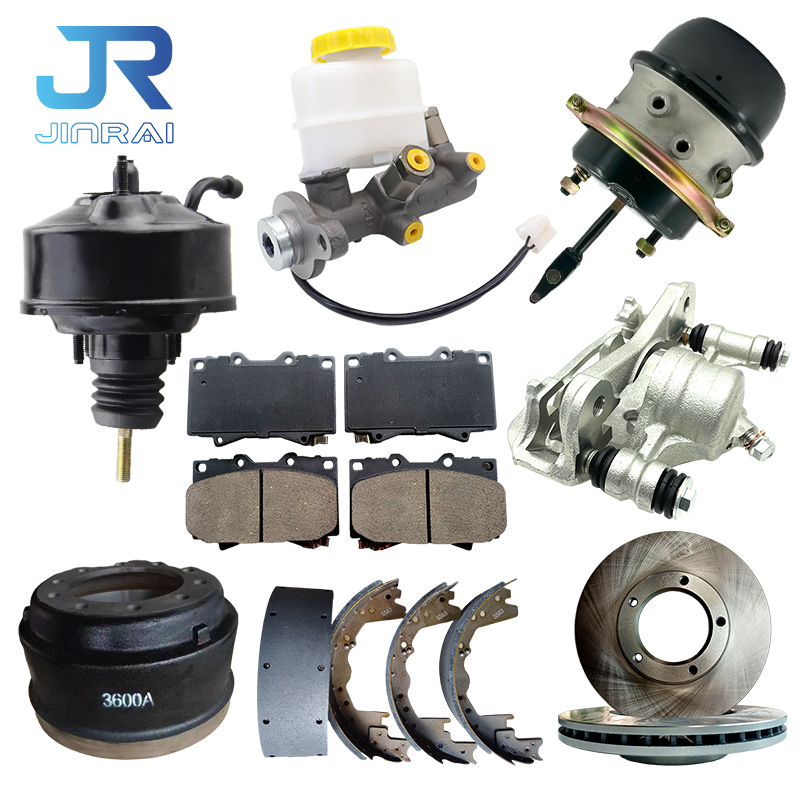

Wholesale Brake Cylinder Manufacturer

We help you spend less, earn more, and unlock bigger margins for your business.

Brake Cylinder Manufacturer in China

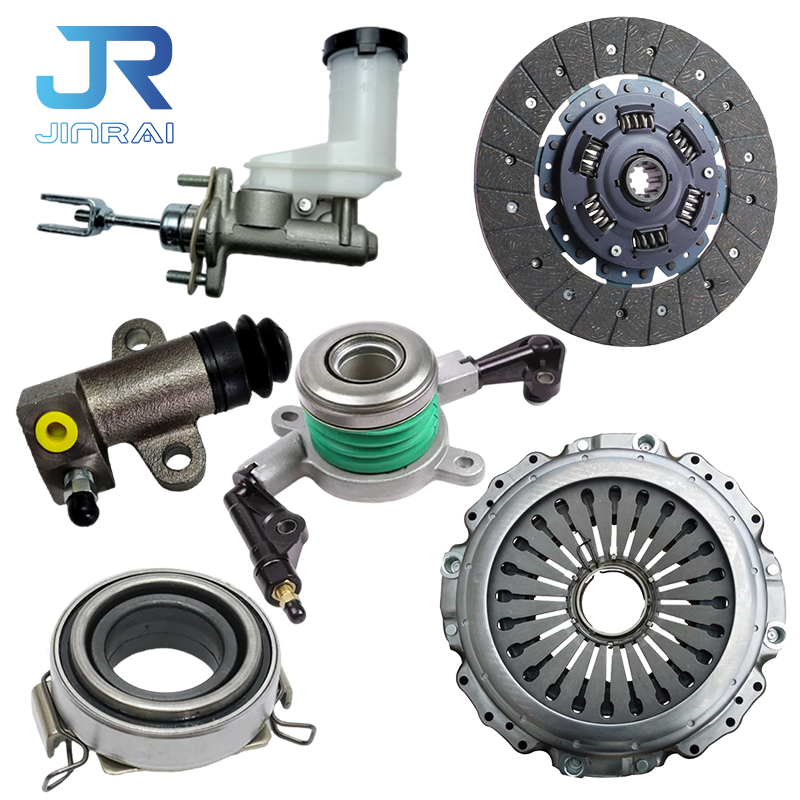

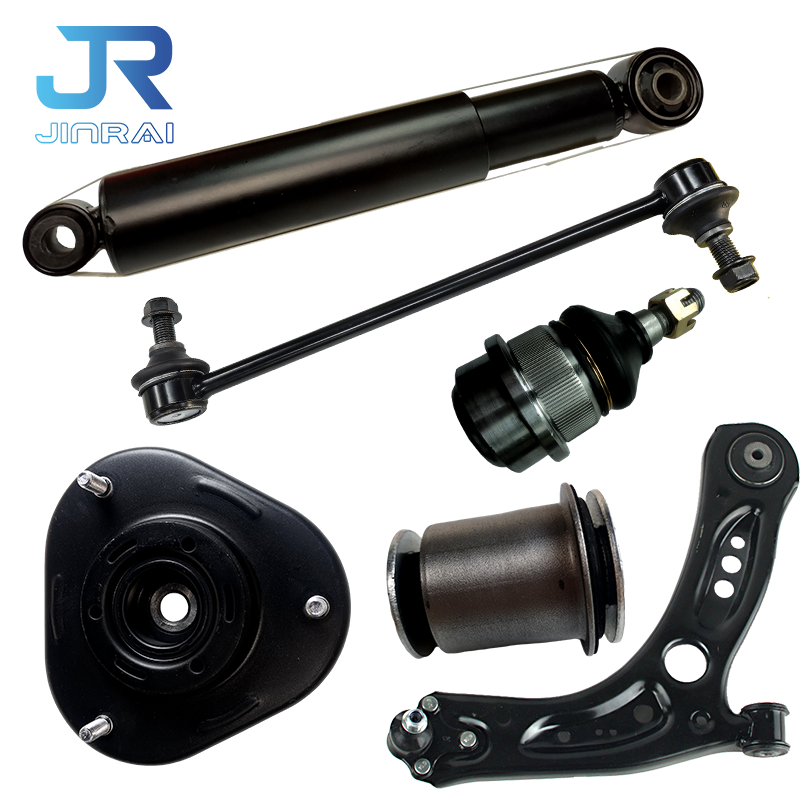

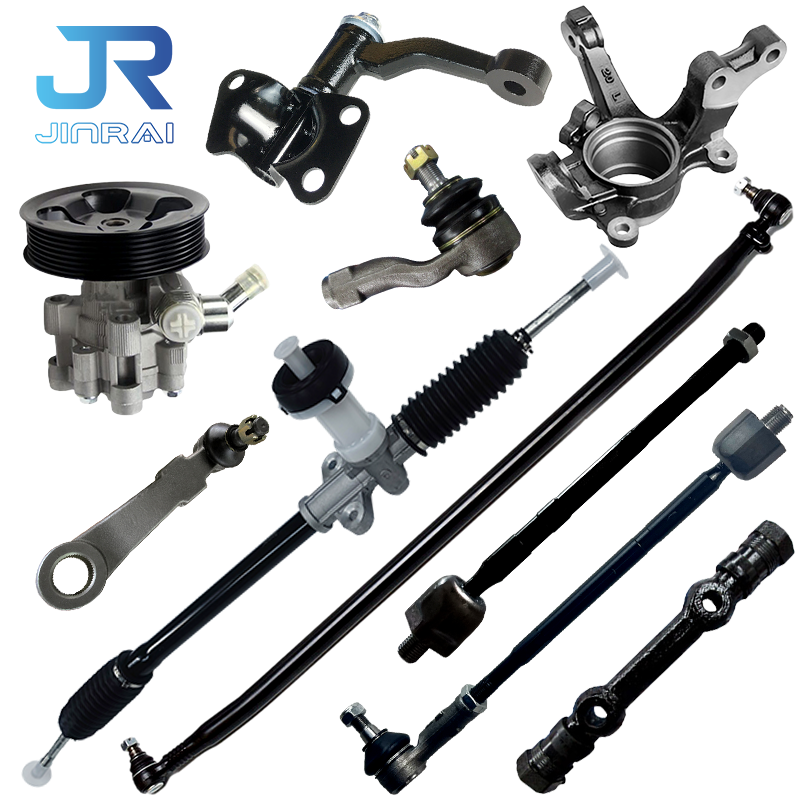

Anhui Goldenstar Auto Parts is a professional brake cylinder manufacturer, supplying high-quality aftermarket brake master cylinder replacements and brake wheel cylinder replacements for cars, trucks, and trailers. Over the years, we’ve focused on doing one thing well—producing reliable hydraulic brake pumps that our customers can trust.

Today, our product range covers the most popular models across Japanese, Korean, European, and American vehicles. Whether your business deals with brake cylinders for any vehicles, you can find all brake cylinders you need here.

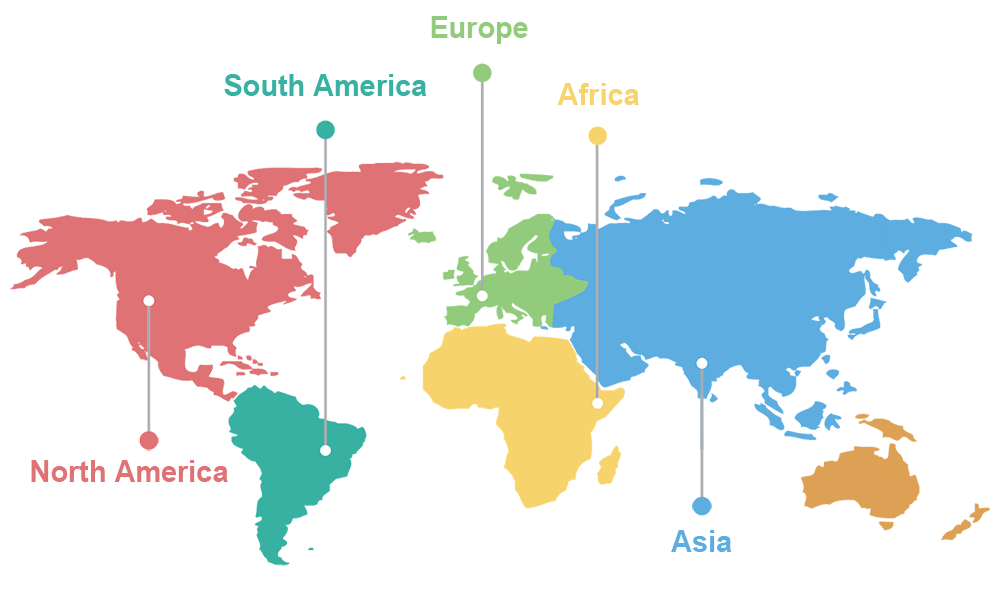

And because of our consistent OE-level quality and excellent service, our brake pumps have earned strong recognition worldwide, and are now sold in more than 80 countries, including South America, North America, Europe, the Middle East, Southeast Asia, and Africa.

Most of our work is helping customers build and grow their own brands. From customized packaging to private-label production, we support each customer in creating products that stand out in their local markets. We’ve already partnered with over 100 brands around the world, and we look forward to building a successful partnership with you too.

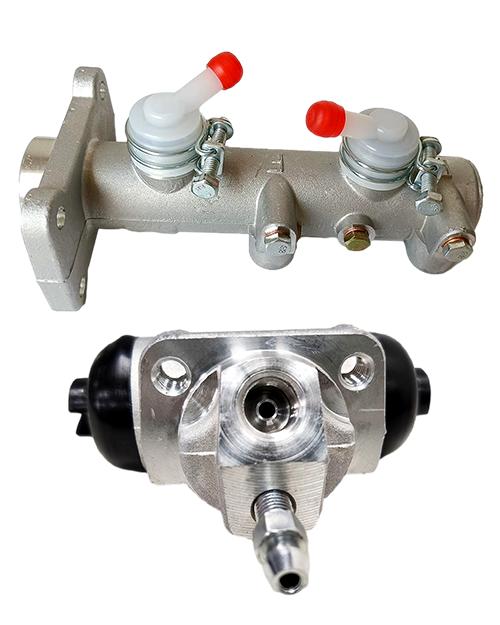

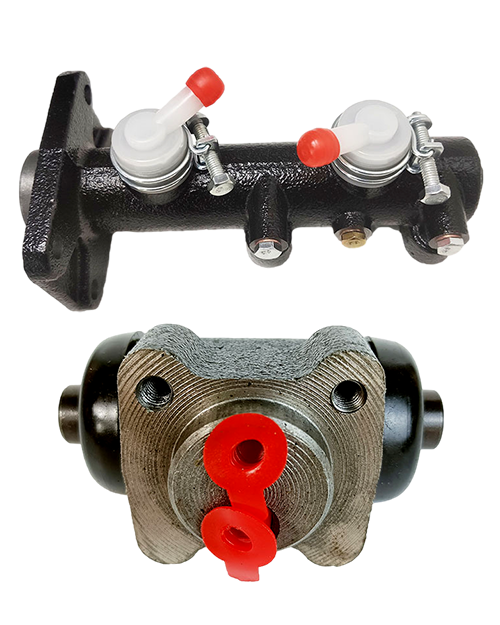

Brake Cylinder Materials

All according to OE standards

Aluminium for Long-Lasting Durability

With excellent resistance to corrosion and brake fluid. Not only extend service life, but also help reduce overall weight.

Iron for High Load Capacity

Offer strong pressure resistance and a stable braking feel, ideal for heavy-duty vehicles that operate under tough conditions.

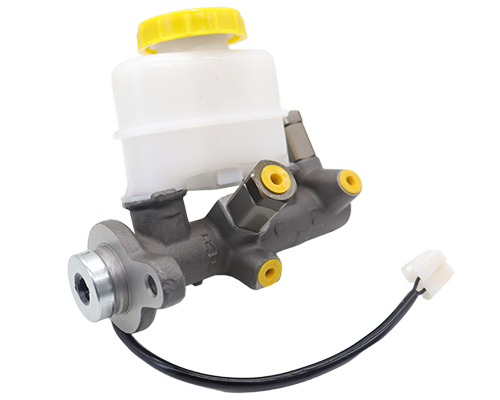

Hydraulic Master Brake Cylinder

The brake master cylinder is a part of the braking system, and its quality directly affects braking response and driving safety. So purchasing the right master cylinder is not just about matching a part number—it’s about ensuring the safety of your clients. When sourcing, pay attention to the material quality, internal seals, machining accuracy, and whether the product meets OE standards. A well-made brake master cylinder keeps your customers safe, reduces complaints, and protects your brand reputation in the market.

Master Brake Cylinder Location?

The brake master cylinder is usually located in the engine bay on the driver’s side, mounted directly on the brake booster, and connected to the brake pedal.

Master Brake Cylinder Function

The brake master cylinder converts the force you apply on the brake pedal into hydraulic pressure. This pressure travels through the brake lines to the wheel cylinders or calipers, allowing the vehicle to slow down or stop.

Brake Master Cylinder Component

- Housing / Body

The main outer shell, usually made of aluminium or iron, which holds all internal parts. - Reservoir (Brake Fluid Tank)

Stores brake fluid and feeds it into the master cylinder. - Pistons (Primary & Secondary Pistons)

Move when you press brake pedal and create hydraulic pressure. - Seals & Rubber Cups

Keep the fluid contained and maintain pressure inside the cylinder. - Return Spring

Pushes the pistons back to their original position after braking. - Snap Rings / Retainers

Hold internal parts in place and ensure the pistons stay aligned.

Signs of a bad brake master cylinder

A failing brake master cylinder can compromise safety, so it’s important to recognize the warning signs:

- Spongy or Soft Brake Pedal

The pedal feels soft or sinks to the floor when pressed. - Brake Fluid Leaks

Fluid around the master cylinder or under the vehicle. - Contaminated Brake Fluid

Dark or dirty fluid in the reservoir. - Brake Warning Light On

Dashboard warning lights may indicate low pressure or a leak. - Poor Braking Performance

Brakes respond slowly or unevenly, requiring more force to stop.

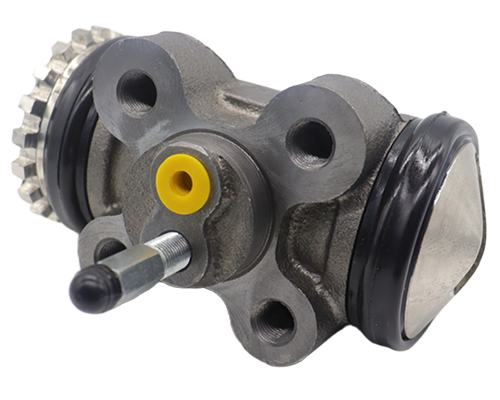

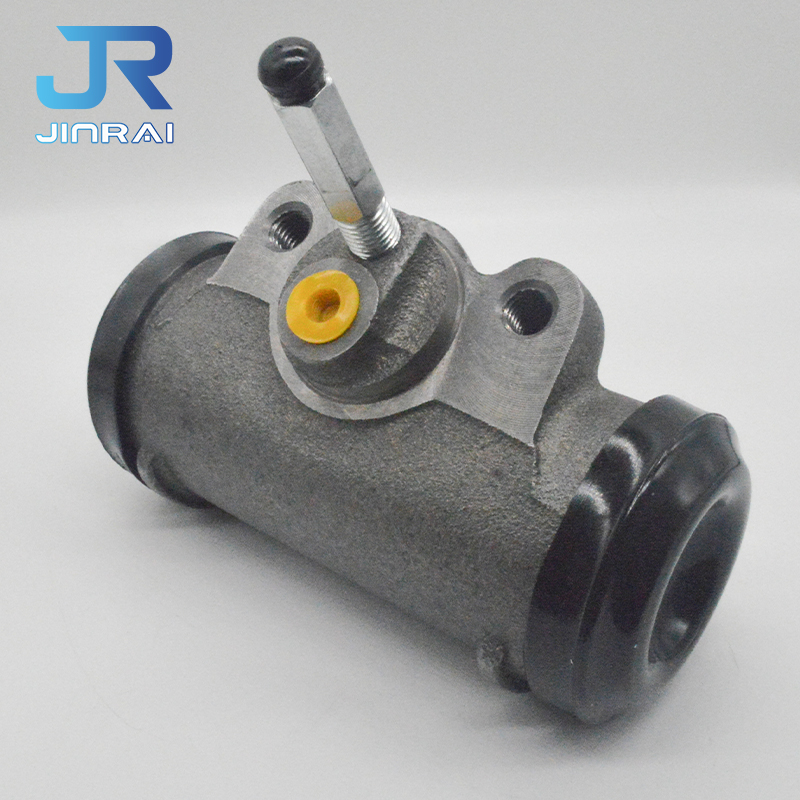

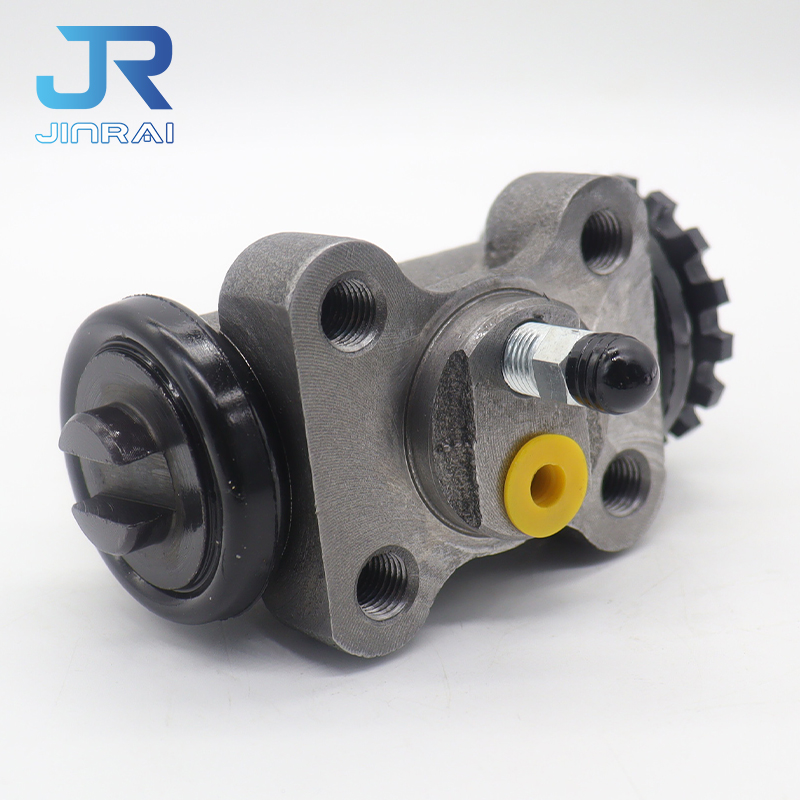

Drum Brake Wheel Cylinder

The brake wheel cylinder is one of the most important parts of the drum brake system. A high-quality wheel cylinder helps prevent fluid leaks, reduces maintenance costs, and keeps customers’ vehicles safe on the road. That’s why choosing a trusted wheel cylinder supplier is essential for long-term performance and confidence.

Brake Wheel Cylinder Location

The brake wheel cylinder is located inside the drum brake assembly, positioned at the top of the brake backing plate, between the two brake shoes.

Wheel Brake Cylinder Function

The brake wheel cylinder’s function is to convert hydraulic brake pressure into mechanical force. When you press the brake pedal, brake fluid pushes the pistons inside the wheel cylinder outward, forcing the brake shoes against the drum. This action generates the friction required for deceleration or stopping.

Brake Wheel Cylinder Component

- Cylinder Body

The metal housing that holds all internal parts and withstands hydraulic pressure. - Pistons (Left & Right)

Two pistons sit at both ends of the cylinder. When brake fluid pressure increases, they push outward to move the brake shoes. - Rubber Boots/ Dust Boots

These rubber covers protect the pistons from dust, dirt, and moisture, preventing corrosion and extending the cylinder’s life. - Cup Seals/ Piston Seals

Rubber seals are fitted on the pistons to keep hydraulic fluid from leaking and to maintain pressure. - Return Springs

Small springs that help retract the pistons after braking. - Bleeder Screw/ Bleeder Valve

A small valve used to bleed air from the brake system during installation or maintenance.

Signs of a bad brake wheel cylinder

- Fluid Around the Wheels

If you find wet or oily spots inside the drum or around the backing plate, that often means the wheel cylinder is leaking. - Your brake pedal feels soft

If the pedal feels soft, spongy, or sinks lower than usual, it could be because the wheel cylinder isn’t holding pressure. - The car doesn’t stop as well as before

Longer stopping distances and weaker braking power. The car may pull left or right when you brake. - Brake shoes wear out unevenly

A sticking or leaking wheel cylinder can make one side wear faster than the other. - Brake warning light turns on

If the system loses too much fluid due to a leak, the brake warning light may come on. - Burning smell or contaminated shoes

Leaking fluid can soak the brake shoes, making them slippery and sometimes causing a burning smell when braking.

Brake Cylinder Factory

Anhui Goldenstar Auto Parts started its brake cylinder factory back in 2005 with a simple goal: to build reliable products that customers can trust. Today, after years of steady growth and customer support, we have more than 100 skilled workers, our own casting plant, and a dedicated assembly factory.

With over twenty CNC machines and more than thirty production lines, our monthly output now reaches 200,000 pieces—a scale that allows us to supply large distributors and markets with confidence.

What really sets Goldenstar apart is not just our equipment, but our commitment. We focus on stable quality, fast delivery, and long-term cooperation. Thanks to this, we have grown into one of China’s leading brake cylinder manufacturers, trusted by partners from many regions around the world.

If you are looking for a supplier who combines capacity, experience, and a down-to-earth attitude toward service, Goldenstar is ready to support your business.

How We Produces OE-Quality Brake Cylinders?

Strong manufacturing. Reliable performance. Consistent quality.

Premium Raw Materials Only

We starts with carefully selected cast iron and aluminum. Every batch is tested before production, ensuring strong, durable brake cylinders that can handle long-term use.

High-Precision Casting & Forging

Our cylinder bodies are formed using advanced casting and forging processes. This gives every part excellent strength and a uniform structure — the foundation of stable braking performance.

CNC Machining for Perfect Accuracy

We uses modern CNC lines to machine every cylinder body with high precision. This guarantees smooth bores, exact dimensions, and a perfect fit — reducing failures and increasing reliability.

Strict Surface Protection

Each brake cylinder receives professional surface treatment, including: Anti-rust coating; Anodizing (for aluminum); Protective plating. This keeps the cylinder corrosion-resistant, even in tough environments.

Professional Assembly Line

Our trained technicians assemble every internal component with care: pistons, seals, springs, dust boots, and bleeder valves. We follow strict assembly standards to ensure stable and consistent performance.

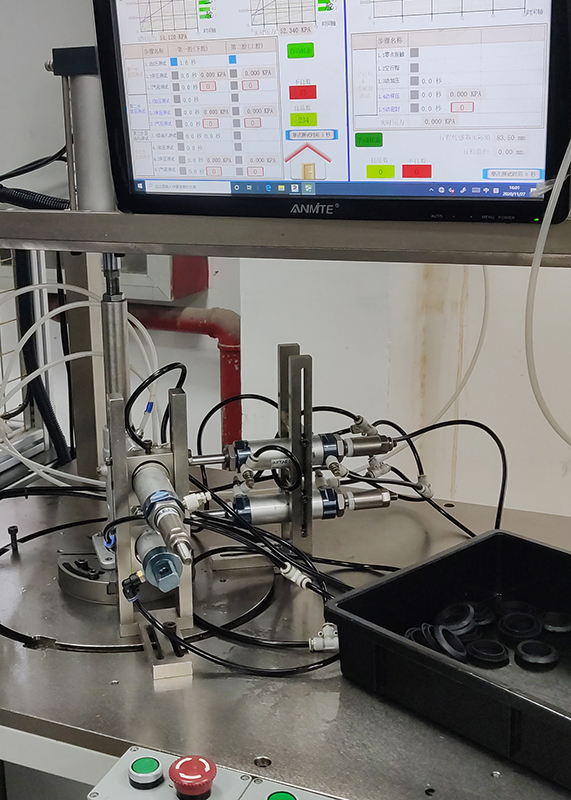

100% Pressure & Leakage Testing

Every brake cylinder is tested. We run high-pressure and leakage tests on all units to make sure they: Seal perfectly; Move smoothly; Hold pressure without failure. Only fully qualified products move to the next step.

Final Quality Inspection

Before packing, each cylinder goes through a final inspection to check appearance, dimensions, and functional performance. This ensures our customers receive products that meet international standards.

Custom Packaging for Your Brand

We provide a full range of packaging options: Custom brand boxes; Barcodes and labels; Protective packing for long-distance shipping. Helping distributors strengthen their market presence.

Our Main Markets

North America

America, Canada, Mexico, Guatemala, El Salvador, Honduras, Costa Rica, Panama

South America

Colombia, Venezuela, Suriname, Ecuador, Peru, Bolivia, Brazil, Argentina, Chile

Europe

Finland, Poland, UK, France, Malta, Spain, Portugal, Andorra, Sweden, Belarus, Monaco

Africa

Egypt, Libya, Sudan, Tunisia, Algeria, Morocco, Kenya, Tanzania, Uganda, Gabon, Burkina Faso, Nigeria, Cape Verde, Côte d’Ivoire, Ghana, Zambia, Angola, Zimbabwe, Malawi, South Africa, Madagascar

Asia

South Korea, Japan, Philippines, Vietnam, Laos, Cambodia, Myanmar, Thailand, Malaysia, Indonesia, Bangladesh, India, Pakistan, Sri Lanka, Iraq, Iran, Syria, Jordan, Lebanon, Israel, Palestine, Saudi Arabia, Bahrain, Qatar, Kuwait, United Arab Emirates, Oman, Yemen, Turkey

Why Choose Us?

As a brake cylinder factory with rich experience, we provide full support to help you grow your business with ease.

OE Quality

Make production according to OE standards

Competitive Price

Give you factory direct selling prices

Lower MOQ

100pcs each model

OEM&ODM

Support do your customized brand package

Warranty

1 Year after you receive our products

Your challenge VS Our solution

We understand your challenges, so we’ve built solutions for you

Your Challenge

- Difficult Communication With Suppliers

“I spend so much time explaining my requirements, but the replies I get are either unclear or come way too late. Some suppliers don’t follow up at all, don’t update me on the order status, or completely misunderstand what I asked for. In the end, it leads to mistakes, delays, and a lot of wasted time on my side.”

- Delivery Delays and Broken Promises

“One of the biggest headaches for me is suppliers who can’t keep their delivery promises. They give me a date, I plan everything around it, and then—right before the deadline—they tell me they need more time. This puts me in a terrible position. My customers start pushing me, my schedule gets messed up, and I’m the one who has to take the blame for something I didn’t cause. Every delay costs me time, trust, and business.”

- Receiving Low or Unstable Quality Products

“I’ve had suppliers send me batches with totally inconsistent quality — some parts are okay, but others fail way too fast. Then I end up dealing with returns, complaints, and extra costs that shouldn’t be my problem in the first place. What’s worse is that some suppliers don’t even take responsibility. They ignore my feedback or pretend nothing is wrong, leaving me to handle the mess.”

- Poor After-Sales Support

“The moment a quality problem happens, some suppliers just disappear. They reply slowly, avoid the issue, or simply refuse to solve it. In the end, I’m the one left dealing with the loss, facing complaints from my customers, and taking the hit to my reputation. It really destroys my confidence in the supplier.”

Our Solution

- Good Communication

We’ve served customers in over 100 countries, so communication is never a barrier. With rich service experience and a deep understanding of brake cylinders, we provide clear, professional support, and we’re available 24/7 to answer your questions quickly.

- Fast Delivery on Time

We produce around 200,000 pieces each month, with a typical lead time of 55 days. Thanks to our strong production capacity, you can count on us to deliver your orders on time, every time, without surprises.

- Only Produce OE Quality Products

From casting to machining to assembly, every step of production is done in-house under our careful supervision. We don’t just finish the products — we test each brake cylinders before it leaves our factory to make sure it meets our strict quality standards.

- Excellent After-Sales Service

We take after-sales support very seriously. If any issue arises, we respond immediately, carefully investigate the problem, and work with you to find a fair solution. Our goal is to make sure your business isn’t affected and that you feel fully supported, giving you peace of mind that we’re always here to back you up.

More Than A Supplier, Your Trusted Partner

Together with our clients, we build stronger markets through trust, quality, and long-term cooperation.

We join in numerous exhibitions every year, including Automechanika Las Vegas, Mexico, Dubai, Shanghai, and the Canton Fair, to connect with customers face-to-face and understand their real market needs.

We warmly welcome customers to visit our factory. Seeing our production, quality control, and teamwork in person builds trust and long-term confidence.

We are more than just a supplier — we share meals, ideas, and moments with our customers, growing together as partners and friends.

Frequently Asked Questions

Everything you want to know about working with us — answered here.

Are you a manufacturer or a trading company?

What is Your MOQ?

Do you offer customized packaging and branding?

What is your warranty policy?

What payment terms do you accept?

Contact Us

You can send us your inquiry lists, requirements, or suggestions using the following form. We will reach you asap.