Wholesale Clutch Cylinder Manufacturer

Lower your costs. Strengthen your margins. Grow your business with confidence.

Clutch Cylinder Manufacturer in China

Anhui Goldenstar Auto Parts is a professional clutch cylinder manufacturer, supplying reliable aftermarket clutch master cylinders and clutch slave cylinders for passenger cars, commercial vehicles, trucks, and trailers.

With years of manufacturing experience, we focus on producing stable, long-lasting hydraulic clutch cylinders designed to meet the demands of global aftermarket purchasers. Each piece is manufactured under strict quality control, ensuring consistent performance, precise fitment, and dependable service life.

Our product range covers popular Japanese, Korean, European, and American vehicle models, making it easy for distributors and wholesalers to source a complete clutch cylinder lineup from one trusted manufacturer.

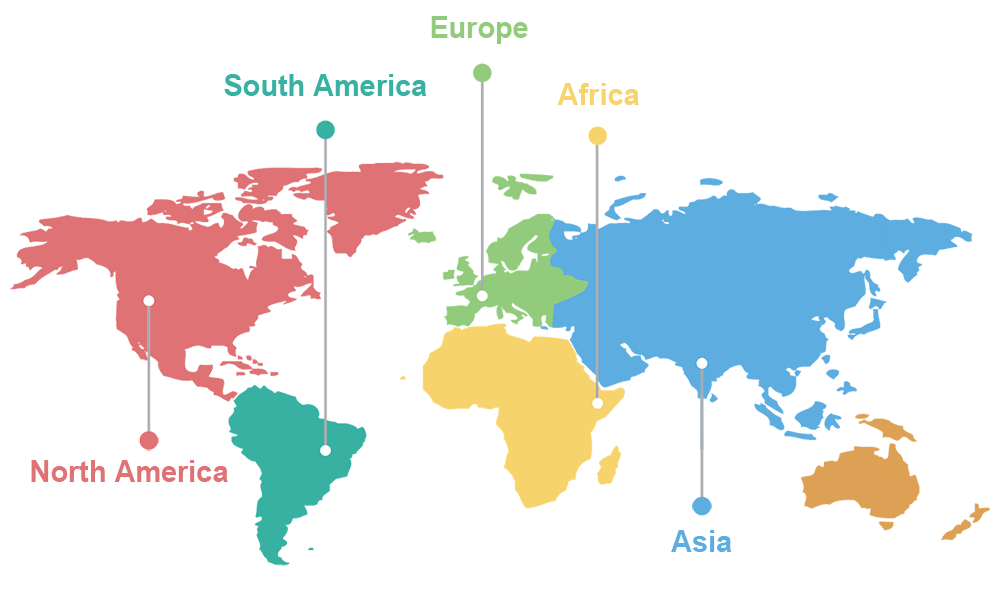

As an experienced clutch cylinder manufacturer, we support customers worldwide with OE-level quality, stable supply, and flexible cooperation. Today, our clutch cylinders are supplied to buyers in over 80 countries, including South America, North America, Europe, the Middle East, Southeast Asia, and Africa.

We also help partners build their own brands through private labeling and customized packaging, supporting long-term growth in local markets.

Our Model Range

What you need is exactly what we offer.

Japanese vehicles

Toyota, Honda, Nissan, Mazda, Subaru, Mitsubishi, Suzuki, Isuzu, Hino, Daihatsu

Korean Vehicles

Hyundai, Kia, Genesis, SsangYong

European Vehicles

DAF, Renault, Peugeot, Citroën, Fiat, Iveco, Volvo, Scania, Land Rover

American Vehicles

Ford, Chevrolet, Dodge, Tesla, Jeep, Cadillac, Buick

German Vehicles

Volkswagen, BMW, Audi, Porsche, Mercedes-Benz, MAN, Opel

Clutch Cylinder Materials

All according to OE standards

Aluminium Clutch Cylinders

offer a balanced combination of lightweight design, corrosion resistance, and cost efficiency.

Iron Clutch Cylinders

focus on high strength and durability, ideal for heavy-duty and high-pressure applications.

Plastic Clutch Cylinders

provide lightweight, corrosion-resistant solutions for cost- and weight-sensitive vehicle models.

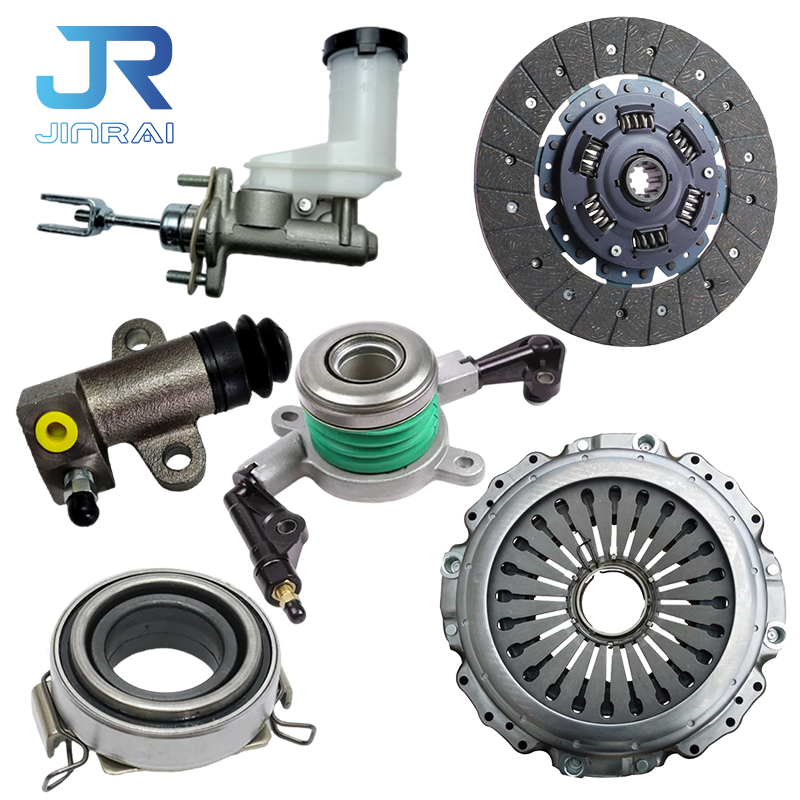

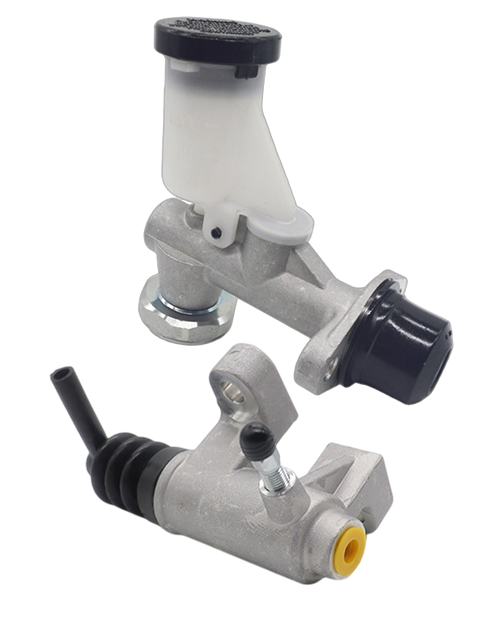

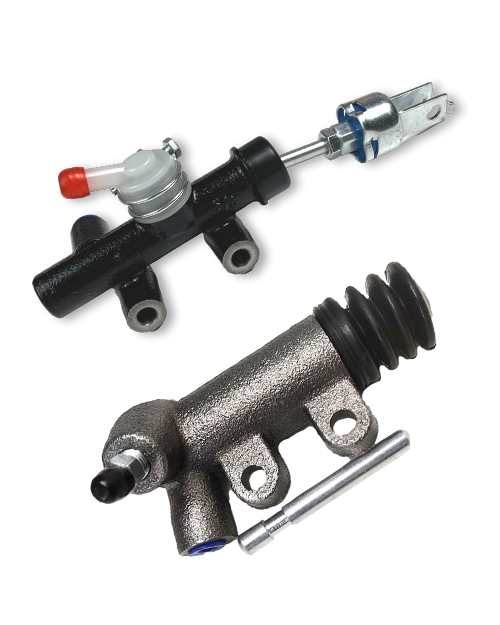

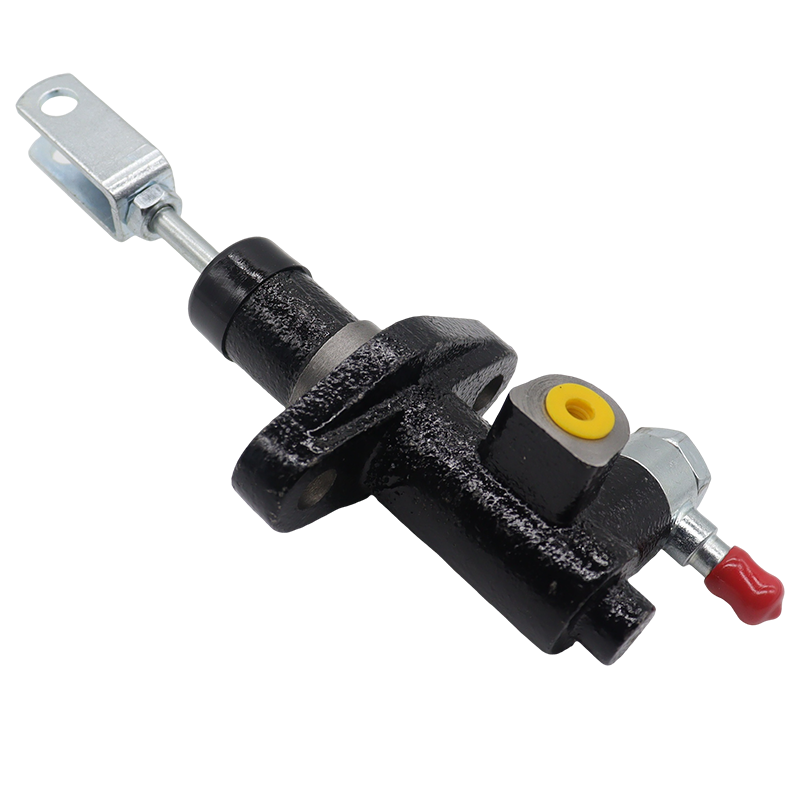

Clutch Master Cylinder

The clutch master cylinder is a vital part of a vehicle’s clutch system, directly affecting pedal response and overall driving performance. Choosing the right clutch master cylinder is more than matching a part number – it ensures reliable operation and customer satisfaction.

When sourcing, pay attention to material quality, internal seals, machining precision, and OE-standard compliance. High-quality clutch master cylinders help you reduce operational issues, minimize complaints, and maintain strong brand reputation in the aftermarket.

Clutch Master Cylinder Location — Why It Matters

Master Clutch Cylinder Function — What You Should Care About

Clutch Master Cylinder Components — Where Quality Makes the Difference

Signs of a Bad Clutch Master Cylinder

Clutch Slave Cylinder

The clutch slave cylinder plays a critical role in smooth clutch disengagement and overall driving performance. A high-quality clutch slave cylinder helps prevent fluid leakage, ensures consistent hydraulic response, and reduces maintenance costs.

Choosing a reliable clutch slave cylinder supplier supports long-term performance, minimizes after-sales issues, and helps you maintain strong brand confidence in the aftermarket.

Clutch Slave Cylinder Location — Why It Matters

Clutch Slave Cylinder Function — What You Should Care About

Clutch Slave Cylinder Components — Where Quality Makes the Difference

Signs of a Bad Clutch Slave Cylinder

Clutch Cylinder Factory

Anhui Goldenstar Auto Parts is a professional clutch cylinder manufacturer since 2005, specializing in high-quality clutch master cylinders and clutch slave cylinders for passenger cars, trucks, and commercial vehicles.

With over 100 skilled workers, our own casting plant, and advanced CNC machines, we produce 200,000 pieces per month, ensuring a stable supply for distributors and wholesalers worldwide.

Focusing on OE-level quality, reliable performance, and timely delivery, Goldenstar helps customers build long-term partnerships and maintain strong brand confidence in the aftermarket.

How We Produces OE-Quality Clutch Cylinders?

Strong manufacturing. Reliable performance. Consistent quality.

Premium Raw Materials Only

Made from high-quality cast iron and aluminum, every clutch cylinder batch is tested before production to ensure long-lasting strength and reliability.

High-Precision Casting & Forging

Each clutch cylinder body is produced with advanced casting and forging, ensuring strong, uniform components that guarantee stable and reliable clutch performance.

CNC Machining for Perfect Accuracy

Each clutch cylinder body is machined on modern CNC lines, delivering accurate bores, consistent dimensions, and perfect fit — providing long-term dependable performance.

Strict Surface Protection

Each clutch cylinder undergoes professional surface treatments, including anti-rust coating, anodizing for aluminum, and protective plating, ensuring excellent corrosion resistance even in demanding environments.

Professional Assembly Line

Our experienced technicians carefully assemble every internal component — including pistons, seals, springs, dust boots, and bleeder valves — in full compliance with strict production standards

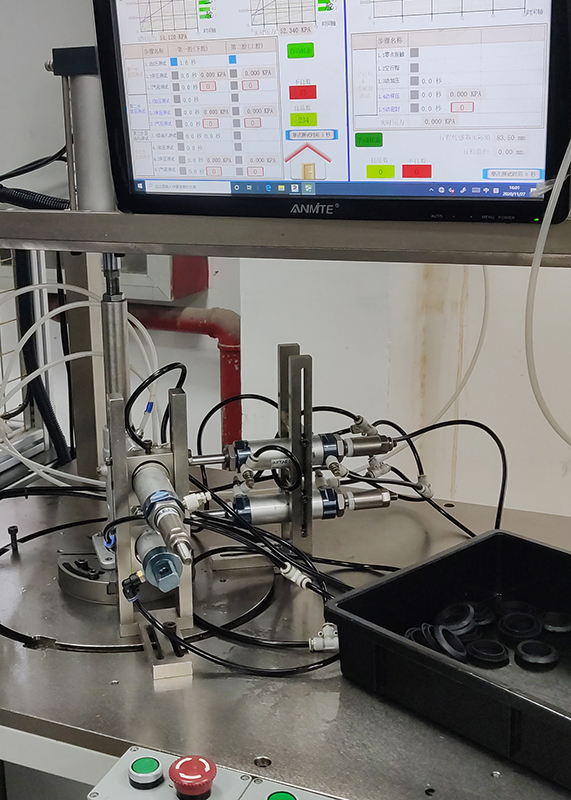

100% Pressure & Leakage Testing

Each clutch cylinder is rigorously tested under high pressure to verify leak-free sealing, smooth movement, and stable pressure performance. Only products that pass all inspections are released for further processing.

Final Quality Inspection

Before packing, each cylinder undergoes a final inspection covering appearance, dimensional accuracy, and functional performance to ensure every product meets international quality standards.

Custom Packaging for Your Brand

We offer a complete range of packaging solutions, including custom brand boxes, barcodes and labeling, helping you strengthen your market presence and brand recognition.

Our Main Markets

North America

America, Canada, Mexico, Guatemala, El Salvador, Honduras, Costa Rica, Panama

South America

Colombia, Venezuela, Suriname, Ecuador, Peru, Bolivia, Brazil, Argentina, Chile

Europe

Finland, Poland, UK, France, Malta, Spain, Portugal, Andorra, Sweden, Belarus, Monaco

Africa

Egypt, Libya, Sudan, Tunisia, Algeria, Morocco, Kenya, Tanzania, Uganda, Gabon, Burkina Faso, Nigeria, Cape Verde, Côte d’Ivoire, Ghana, Zambia, Angola, Zimbabwe, Malawi, South Africa, Madagascar

Asia

South Korea, Japan, Philippines, Vietnam, Laos, Cambodia, Myanmar, Thailand, Malaysia, Indonesia, Bangladesh, India, Pakistan, Sri Lanka, Iraq, Iran, Syria, Jordan, Lebanon, Israel, Palestine, Saudi Arabia, Bahrain, Qatar, Kuwait, United Arab Emirates, Oman, Yemen, Turkey

Why Choose Us?

As a clutch cylinder factory with rich experience, we provide full support to help you grow your business with ease.

OE Quality

Make production according to OE standards

Competitive Price

Give you factory direct selling prices

Lower MOQ

100pcs each model

OEM&ODM

Support do your customized brand package

Warranty

1 Year after you receive our products

Your challenge VS Our solution

We understand your challenges, so we’ve built solutions for you

Your Challenge

- Difficult Communication With Suppliers

“I spend so much time explaining exactly what I need, but the replies are often vague, late, or missing important details. Some suppliers disappear after the order is placed, don’t keep me informed, or completely get my requirements wrong. In the end, I’m the one dealing with mistakes, delays, and wasted time.”

- Delivery Delays and Broken Promises

“One of my biggest headaches is working with suppliers who fail to keep their delivery promises. They give me a shipping date, I plan my entire schedule around it — and then, just before the deadline, they suddenly ask for more time. This puts me in an impossible position. My customers start pressuring me, my schedule is completely disrupted, and I’m the one who has to take responsibility for a problem I didn’t create. Every delay costs me time, trust, and real business.”

- Receiving Low or Unstable Quality Products

“I have experienced serious quality inconsistency in shipments — some parts meet expectations, while others fail prematurely. This leads to returns, customer complaints, and unnecessary costs that significantly impact my business. Unfortunately, some suppliers avoid responsibility, disregard feedback, and leave me to resolve the consequences on my own.”

- Poor After-Sales Support

“When quality problems occur, some suppliers become unresponsive, delay their replies, or avoid taking responsibility.

As a result, I’m left handling financial losses, customer complaints, and damage to my business reputation — which seriously undermines my trust in the supplier.”

Our Solution

- Clear & Efficient Communication

Serving customers in more than 100 countries, we understand how to communicate clearly across markets. Our experienced team, with strong technical knowledge of clutch cylinders, is always available to provide fast, accurate, and professional support whenever you need it.

- Fast Delivery on Time

We manufacture approximately 200,000 units each month, with a typical lead time of 55 days.

Thanks to our robust production capacity and strict scheduling, you can rely on us to deliver your orders on time, every time — no surprises, no delays.

- Only Produce OE Quality Products

From casting to machining to assembly, every step of production is done in-house under our careful supervision. We don’t just finish the products — we test each brake cylinders before it leaves our factory to make sure it meets our strict quality standards.

- Excellent After-Sales Service

We take after-sales support very seriously. If any issue arises, we respond immediately, carefully investigate the problem, and work with you to find a fair solution. Our goal is to make sure your business isn’t affected and that you feel fully supported, giving you peace of mind that we’re always here to back you up.

More Than A Supplier, Your Trusted Partner

Together with our clients, we build stronger markets through trust, quality, and long-term cooperation.

We join in numerous exhibitions every year, including Automechanika Las Vegas, Mexico, Dubai, Shanghai, and the Canton Fair, to connect with customers face-to-face and understand their real market needs.

We warmly welcome customers to visit our factory. Seeing our production, quality control, and teamwork in person builds trust and long-term confidence.

We are more than just a supplier — we share meals, ideas, and moments with our customers, growing together as partners and friends.

Frequently Asked Questions

Everything you want to know about working with us — answered here.

Are you a manufacturer or a trading company?

What is Your MOQ?

Do you offer customized packaging and branding?

What is your warranty policy?

What payment terms do you accept?

Contact Us

You can send us your inquiry lists, requirements, or suggestions using the following form. We will reach you asap.