Wholesale Brake Parts Manufacturer

We make your sourcing easier, your margins higher, and your success bigger — because your growth is our priority.

Brake Parts Manufacturer in China

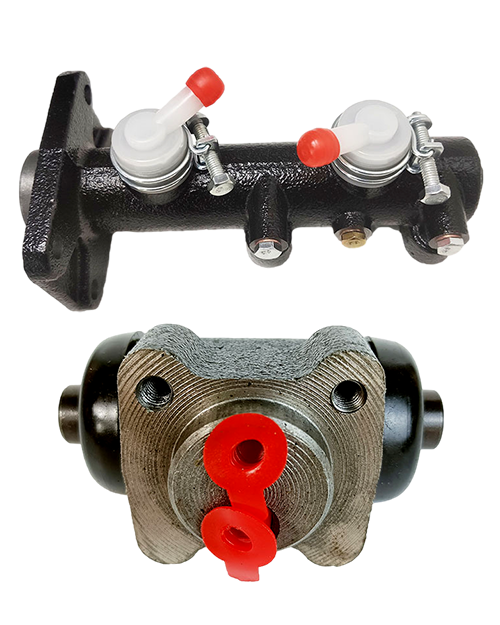

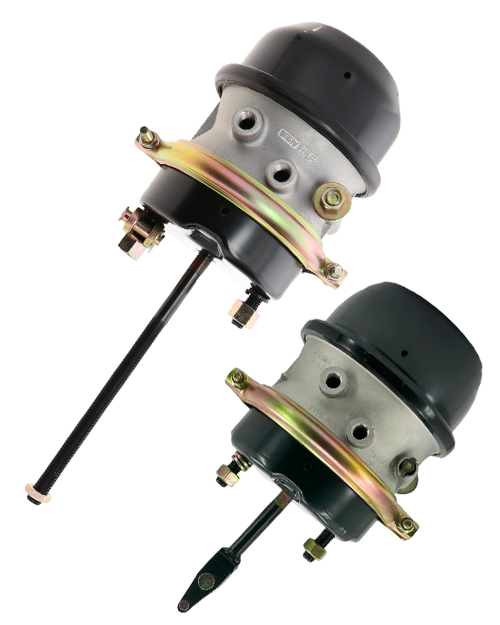

Anhui Goldenstar is a trusted supplier of high-quality brake parts for the global automotive aftermarket. We focus on delivering OE-grade products, including brake cylinders, brake pads, brake shoes, brake calipers, brake discs, brake drums, brake boosters, and repair kits.

Our brake products range covers Japanese, Korean, European, and American vehicles, including passenger cars, trucks, and commercial vehicles — ensuring full coverage of fast-moving models in the market.

Today, Goldenstar brake components are widely sold across North America, South America, Europe, the Middle East, and Southeast Asia. Many of our partners have successfully established and grown their own brands with our support, receiving positive market feedback and strong trust from end users.

Your success starts with a better supplier — choose Goldenstar, choose growth.

Our Brake Parts Range

Cover all you need

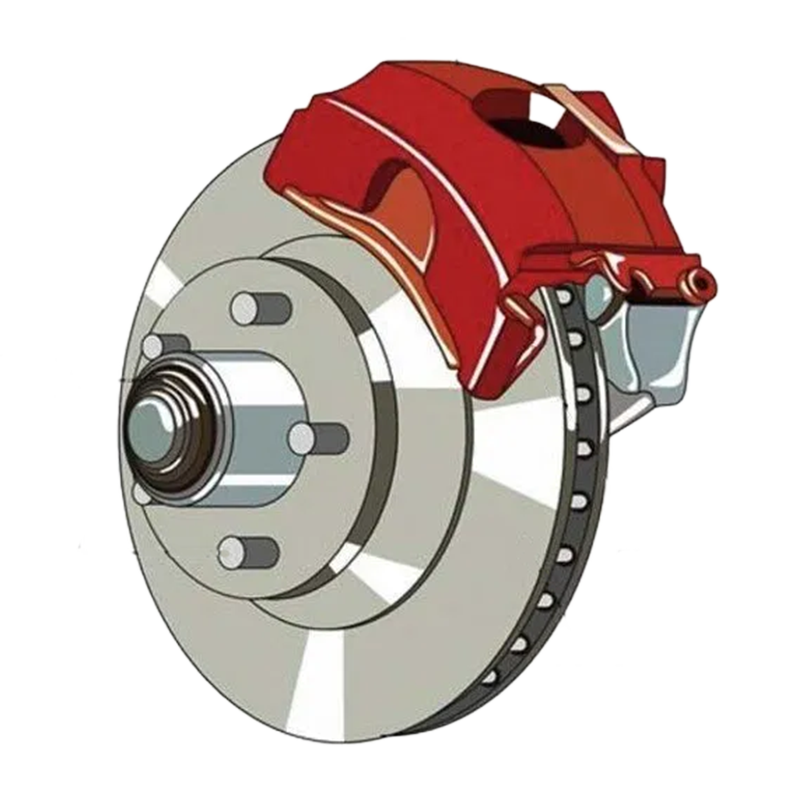

Disc Brake

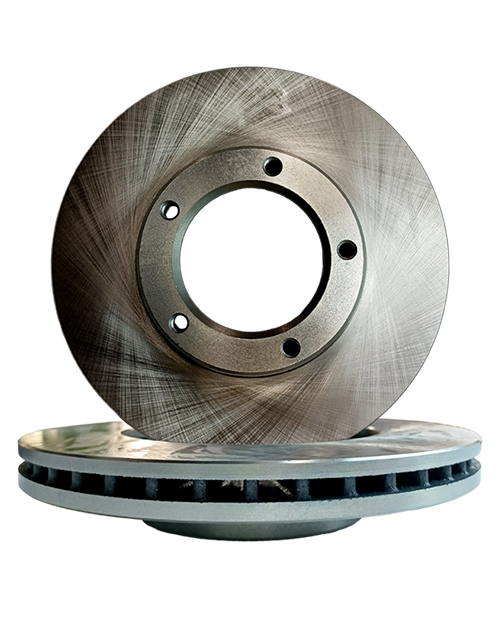

A disc brake system uses brake pads and a caliper to clamp onto a spinning brake disc, giving the vehicle strong, stable stopping power. It handles heat well, performs reliably at high speeds, and offers a smooth, responsive brake feel. A well-maintained disc brake system ensures safer driving and more confident control on every road.

Customers are always looking for stable braking performance, low noise, and long service life, and that’s exactly what Goldenstar is committed to providing.

disc brake system components

A disc brake system is made up of several key parts that work together to safely stop a vehicle:

Brake Disc (Rotor): The round metal plate that spins with the wheel. The brake pads clamp onto it to create friction.

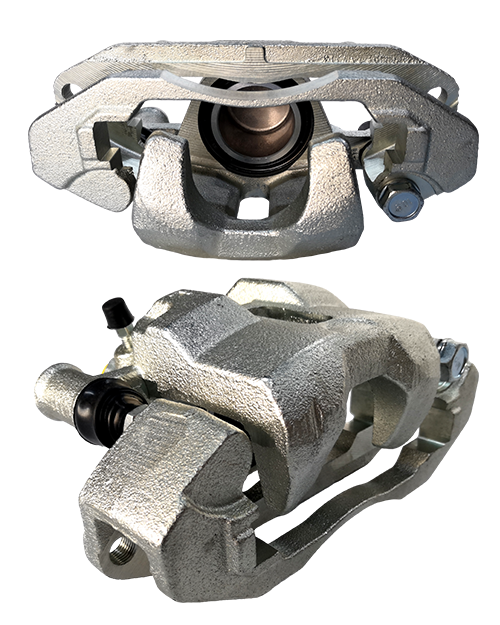

Brake Caliper: The part that houses the brake pads and pushes them against the rotor. Can be fixed or floating type.

Brake Pads: Friction material that grips the disc to slow the wheel. Pads wear over time and need replacement.

Brake Lines and Hydraulic System: Includes brake fluid, hoses, and brake master cylinder that transfer the force from your foot on the pedal to the caliper.

how does a disc brake system work

A disc brake system works by using friction to slow or stop a vehicle. When the brake pedal is pressed, hydraulic pressure pushes the brake pads against a spinning disc (rotor). This contact creates friction, which slows down the wheel. The rotor also helps dissipate heat, keeping the brakes effective and preventing overheating.

Advantage of Disc Brake System

Stronger, More Stable Braking

Disc brakes provide consistent stopping power, even during sudden or repeated braking.Excellent Heat Dissipation

Because the rotor is exposed to open air, heat escapes quickly, reducing brake fade and keeping performance stable.Better High-Speed Performance

Disc brakes maintain strong braking force during highway driving, mountain roads, and long downhill sections.Improved Wet-Weather Braking

Water is quickly pushed away from the disc surface, allowing the brakes to recover faster in rain.Smooth, Responsive Brake Feel

Drivers get a quicker and more controlled braking response, improving overall driving comfort and safety.Lower Risk of Deformation

The rigid structure of the disc reduces the chance of warping compared to drum brakes.Easier Maintenance and Inspection

Discs and pads are exposed and easy to visually check, making maintenance faster and more cost-effective.

Where Disc Brake Systems Are Commonly Used

Passenger Cars

Provide stable, everyday braking for city and highway driving.SUVs and Crossovers

Handle heavier vehicle weight and offer reliable control on varied terrain.Commercial Vehicles

Used on vans, light trucks, and delivery vehicles that require strong, repeated braking.High-Performance and Sports Cars

Deliver precise braking control at high speeds and during aggressive driving.Electric and Hybrid Vehicles

Support regenerative braking systems and maintain smooth stopping performance.Off-Road and Utility Vehicles

Offer consistent braking in muddy, wet, or uneven environments.

Signs Your Disc Brake System Needs Attention

Vibrations in the Steering Wheel or Pedal

Often caused by warped brake discs.Squeaking or Grinding Noises

Indicates worn or damaged brake pads.Longer Braking Distance

Could be due to uneven wear or low brake fluid.Soft or Spongy Brake Pedal

May signal air in the brake lines or hydraulic issues.Uneven Brake Pad or Disc Wear

Shows misalignment or caliper problems.Burning Smell During Braking

Often caused by overheating or dragging brakes.

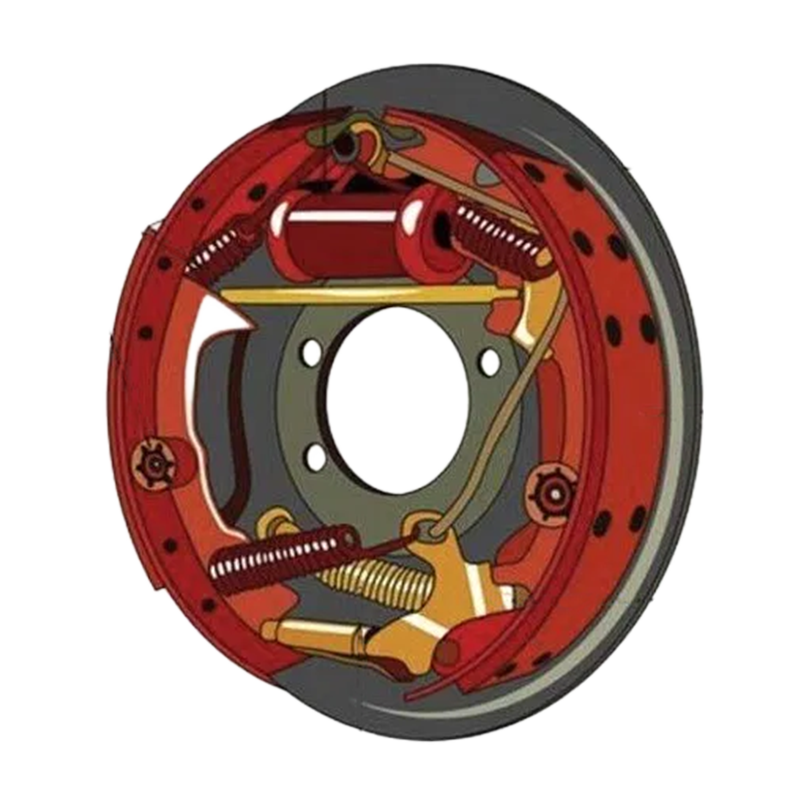

Drum Brake

Drum brakes deliver powerful braking at lower speeds, provide excellent parking brake performance, and offer a cost-effective solution with easy maintenance. With the right design and materials, they remain durable, consistent, and trustworthy throughout years of use.

Partnering with Goldenstar, you will get a competitive price, high-quality products, and long-term success.

Key Components of a Drum Brake System

A drum brake system may look simple, but every part has a precise job:

Brake Drum — Rotates with the wheel; braking force is applied to its inner surface

Brake Shoes & Linings — Create friction when pushed outward

Wheel Cylinder — Uses hydraulic pressure to move the shoes

Return Springs — Pull the shoes back once braking stops

Adjuster — Keeps the gap correct to ensure consistent performance

Backing Plate — The strong foundation that holds everything together

Every component’s quality directly affects braking power and service life.

How a Drum Brake System Stops the Vehicle?

The process is straightforward and highly reliable:

Driver presses the brake pedal

Hydraulic fluid travels to the wheel cylinder

The cylinder pushes the brake shoes outward

Shoes press against the drum and generate friction

The wheel slows and the vehicle stops

When the pedal releases, springs pull the shoes back

The enclosed design helps protect parts from dust and water, maintaining stable performance.

Why Drum Brakes Still Matter?

Even as disc brakes grow more common, drum brakes hold strong advantages:

Excellent braking force at lower speeds

Integrated parking brake capability

Better protection from mud, sand, and water

Lower cost and more economical to maintain

Strong performance for vehicles carrying heavy loads

This is why they remain widely used in many vehicle segments.

Where Drum Brakes Are Commonly Installed?

You’ll still see drum brakes in:

Rear axles of economy cars

Pickup trucks and light commercial vehicles

SUVs in emerging markets

Vans and small buses

Some trucks with heavy-load requirements

They are especially favored in regions where road conditions are rough and maintenance costs matter.

Signs It’s Time to Check or Replace Drum Brakes

If any of these appear, the system may need service:

Longer stopping distance

Grinding or scraping noises

Burning smell during braking

Vehicle pulls to one side

Soft or low brake pedal feel

Parking brake loses effectiveness

Timely inspection means safer driving and fewer costly repairs later.

Why Choose Us?

As a brake parts supplier with rich experience, we provide full support to help you grow your business with ease.

OE Quality

Make production according to OE standards

Competitive Price

Give you factory direct selling prices

Lower MOQ

100pcs each model

OEM&ODM

Support do your customized brand package

Warranty

1 Year after you receive our products

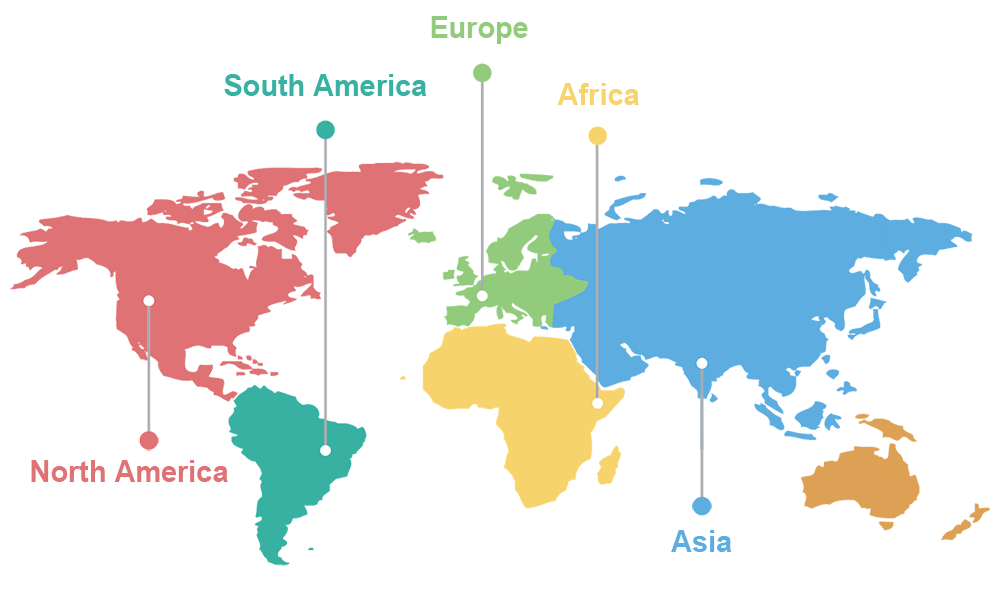

Our Main Markets

North America

America, Canada, Mexico, Guatemala, El Salvador, Honduras, Costa Rica, Panama

South America

Colombia, Venezuela, Suriname, Ecuador, Peru, Bolivia, Brazil, Argentina, Chile

Europe

Finland, Poland, UK, France, Malta, Spain, Portugal, Andorra, Sweden, Belarus, Monaco

Africa

Egypt, Libya, Sudan, Tunisia, Algeria, Morocco, Kenya, Tanzania, Uganda, Gabon, Burkina Faso, Nigeria, Cape Verde, Côte d’Ivoire, Ghana, Zambia, Angola, Zimbabwe, Malawi, South Africa, Madagascar

Asia

South Korea, Japan, Philippines, Vietnam, Laos, Cambodia, Myanmar, Thailand, Malaysia, Indonesia, Bangladesh, India, Pakistan, Sri Lanka, Iraq, Iran, Syria, Jordan, Lebanon, Israel, Palestine, Saudi Arabia, Bahrain, Qatar, Kuwait, United Arab Emirates, Oman, Yemen, Turkey

Frequently Asked Questions

Everything you want to know about working with us — answered here.

Are you a manufacturer or a trading company?

We are a brake parts manufacturer in China, and we are also a trading company, shipping high-quality brake parts to all customers around the world.

What is Your MOQ?

The MOQ is 100pcs each model. For new client who want to check our quality, we also support 50pcs each model if we have assembly stock.

Do you offer customized packaging and branding?

We offer full brand packaging customization, including logo printing on products and designing color bags, color boxes, and outer cartons to make your brand stand out.

What is your warranty policy?

Our warranty is one year after receiving our goods. If any quality issues arise, we will fully cooperate and offer a 100% negotiated compensation to ensure a satisfactory solution.

What payment terms do you accept?

T/T payment, 30% deposit, 70% balance before delivery.

Contact Us

You can send us your inquiry lists, requirements, or suggestions below. We will reach you asap.