Wholesale Brake Pad Manufacturer

We’re here to help you cut costs, grow your profits, and boost your business with confidence.

Brake Pad Manufacturer in China

As one of the well-known disc brake pad manufacturers in China, Anhui Goldenstar Auto Parts has already developed more than 2,000 brake pad models. We focus on ceramic, low-metallic, and semi-metallic materials, and we’ve created 26 different formulas to match different road conditions and market needs.

We have our own lab and testing equipment, which allows us to guarantee that every brake pad is asbestos-free, with no dust, no noise, and a long service life. It’s the kind of quality you can confidently sell to your customers.

All our production processes follow ISO 9001 and IATF 16949 standards to ensure OE-level quality. More than 600 of our brake pad models have ECE R90 and AMECA certifications, and we can also arrange those certifications based on the models you order—making your import process easier and worry-free.

If you’re looking for a reliable brake pad manufacturer with strong quality and competitive prices, feel free to contact us. We’re ready to support your business and help you grow your market.

Brake Pad Materials

Ceramic Brake Pad

Quiet braking

Low dust, cleaner wheels

Smooth and stable performance

Long lifespan

Low-Metallic Brake Pad

Good braking power

Better heat dissipation

Slight noise and some dust

Balance between performance and cost

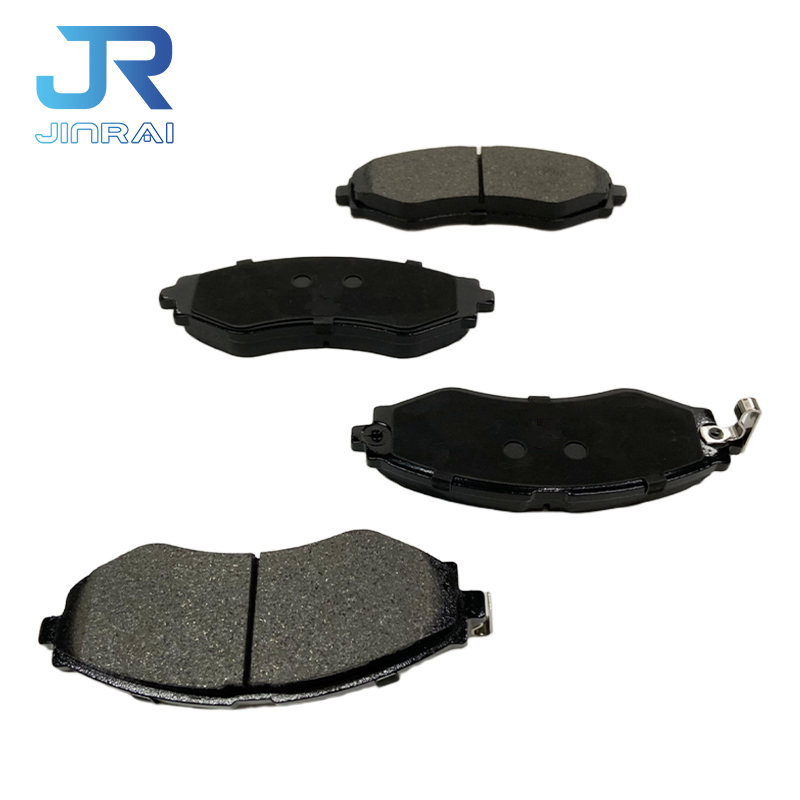

Our Brake Pads Application

What you need is exactly what we offer.

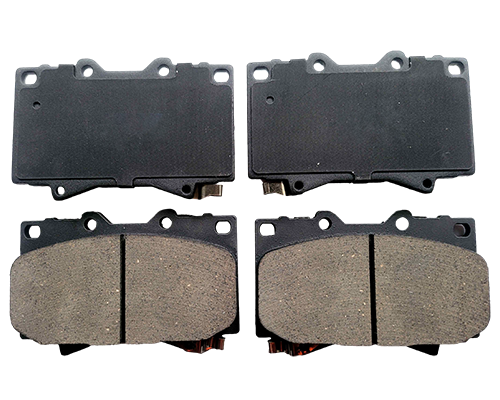

Japanese vehicles

Toyota, Honda, Nissan, Mazda, Subaru, Mitsubishi, Suzuki, Isuzu, Hino, Daihatsu

Korean Vehicles

Hyundai, Kia, Genesis, SsangYong

European Vehicles

DAF, Renault, Peugeot, Citroën, Fiat, Iveco, Volvo, Scania, Land Rover

American Vehicles

Ford, Chevrolet, Dodge, Tesla, Jeep, Cadillac, Buick

German Vehicles

Volkswagen, BMW, Audi, Porsche, Mercedes-Benz, MAN, Opel

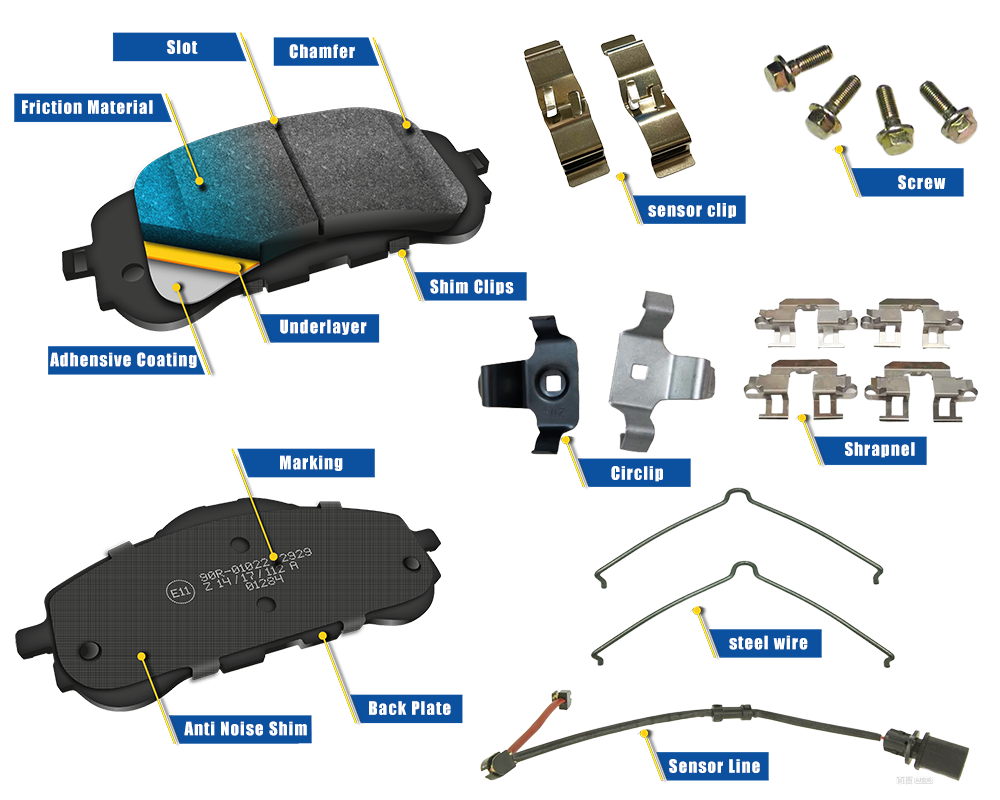

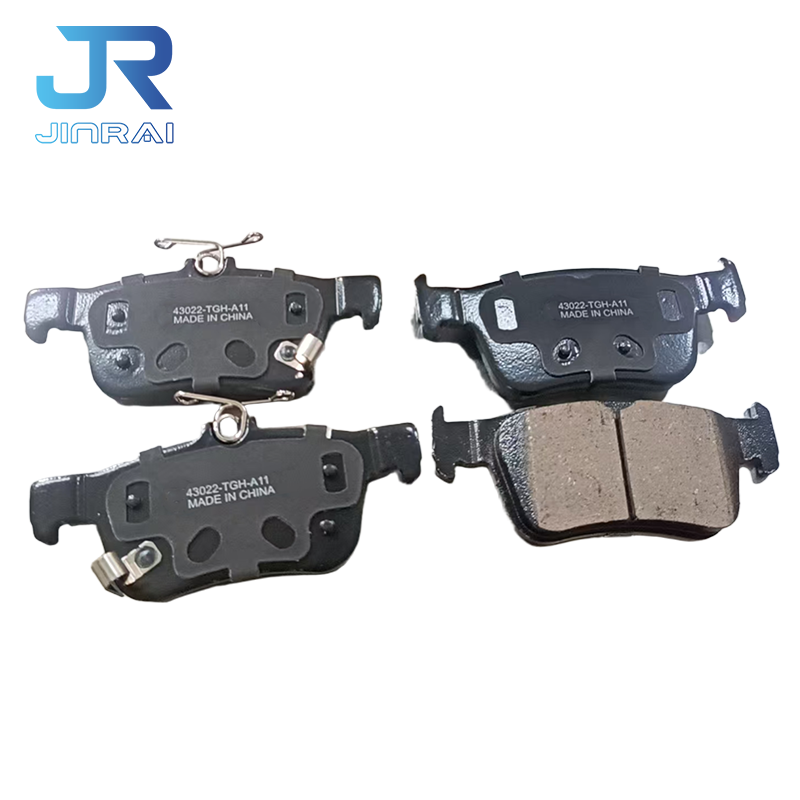

Brake Pad Accessories

By using high-quality materials and tighter production standards, we ensure each component delivers better braking power, longer life, and a smoother driving experience. Below is what goes into our brake pads and why our customers trust our quality.

Made from Q235 low-carbon steel with a hardness of 120–180HB and a thickness of 5–5.5 mm. We control the flatness to 0.01 mm, giving you a strong, accurate back plate that ensures stable braking and reliable bonding.

This is the main working part of the brake pad. We offer ceramic, low-metallic, and semi-metallic material. Standard thickness is 15 mm, and our friction coefficient is set at 0.37 to deliver steady, dependable braking performance.

To keep braking quiet, we provide three shim options: stainless steel, linen finish, and rubber (including Trelleborg and Wolverine). These help reduce vibration and noise, giving drivers a smoother experience.

We also include all necessary accessories for installation, like sensor clip, screw, circlip, shrapnel, steel wire and sensor line, making your product easier to sell and more convenient for your customers.

Ceramic Brake Pad

Our ceramic brake pads are made with copper, zinc, and aluminum, with no steel fiber and less than 3% other metals. The density is 1.8–2.3 g/cm³, giving stable and clean performance. With imported resin and mineral fibers, the pads keep the disc clean, avoid noise, protect the rotor, and never rust. They offer smooth braking, quick response, and reliable insulation—quality you can trust for long-term use.

ceramic brake pads pros and cons

Pros

Cleaner wheels – Ceramic generates light, low-dust particles that don’t stick to the rims.

Quiet performance – Reduced vibration and less squealing for a smoother driving experience.

Long service life – Ceramic material wears slowly, offering longer durability.

Stable braking – Consistent performance across a wide range of temperatures.

Rotor-friendly – Less abrasive, helping protect the brake disc from excessive wear.

Rust-free – Ceramic won’t absorb water or corrode, ideal for wet or humid regions.

Cons

Higher cost – Usually more expensive than semi-metallic pads.

Not for heavy-duty loads – Less suitable for trucks carrying heavy cargo or extreme high-heat conditions.

Softer initial bite – May feel slightly gentler at the first touch of the pedal.

Lower heat dissipation – Releases heat slower than semi-metallic pads in repeated hard braking.

how long do ceramic brake pads last?

Our ceramic brake pads generally last around 40,000–50,000 km, giving customers longer use and fewer replacements.

What Types of Vehicles Are Ceramic Brake Pads Suitable For?

Mainly used in passenger cars, such as sedans, compact cars, and family SUVs. They are ideal for daily driving where quiet, clean, and smooth braking is preferred.

ceramic vs metallic brake pads

Ceramic brake pads focus on comfort and cleanliness, while metallic pads deliver stronger stopping power for demanding conditions. If you care more about smooth driving and low maintenance, ceramic is the better option; if you need durability under heavy loads, metallic is the way to go.

Low-Metallic Brake Pad

Our low-metallic brake pads contain 5–20% steel fiber with a density of 2.0–2.5 g/cm³, giving them strong and stable braking performance. We use high-quality mineral fibers to keep the brake disc from turning black, reduce noise, and prevent rust. The pads offer a comfortable pedal feel, quick braking response, and reliable insulation—making them a solid choice for buyers who want both performance and value.

Low-Metallic Brake Pads Pros and Cons

Pros

Stronger braking power – Higher metal content gives a sharper initial bite and confident stopping performance.

Better heat dissipation – Metal fibers release heat quickly, ideal for higher temperatures or heavier driving conditions.

Quick pedal response – More sensitive and reactive for drivers who want a firm, sporty brake feel.

Cost-effective option – Generally more affordable than ceramic pads while still offering solid performance.

Cons

More brake dust – May darken the wheels and disc over time.

Higher noise levels – Can produce more squeal or vibration compared to ceramic pads.

Faster rotor wear – Metal fibers can be more abrasive on the brake disc.

Less comfort-focused – Not the best choice for buyers who prioritize quiet, clean, and smooth braking.

How Long Do Low-Metallic Brake Pads Last?

Our low-metallic brake pads usually run for about 30,000–40,000 km, offering a good balance of durability and performance.

What Types of Vehicles Are Low-Metallic Brake Pads Suitable For?

Commonly used in mid-size cars, larger SUVs, and small trucks. They fit markets that need stronger braking performance with good heat dissipation.

Semi-Metallic Brake Pad

Our semi-metallic brake pads contain over 20% steel fiber and iron powder, giving them strong durability and reliable braking power. They are widely used in the aftermarket because of their solid performance, stable quality, and excellent value, making them a popular choice for distributors looking for dependable products with high demand.

Semi-Metallic Brake Pads Pros and Cons

Pros

Strong braking power – High metal content delivers excellent stopping performance and a solid initial bite.

Great heat dissipation – Metal fibers conduct heat efficiently, keeping the system stable during repeated or heavy braking.

High durability – handles high temperatures and tough driving conditions better than many ceramic or low-metallic pads.

Cost-effective – A practical choice for buyers looking for reliable performance at a competitive price.

Cons

More noise – Can produce more squeal and vibration than ceramic pads.

Higher dust levels – Generates darker dust that is more visible on wheels and rotors.

Faster rotor wear – Metal fibers can be more abrasive on brake discs.

Less comfort – Braking feel may be rougher compared to ceramic options.

How Long Do Semi-Metallic Brake Pads Last?

Semi-metallic brake pads have a service life of around 30,000 km, which is ideal for heavier or more demanding driving conditions.

What Types of Vehicles Are Semi-Metallic Brake Pads Suitable For?

Suitable for heavy-duty vehicles like pickup trucks, commercial vans, and off-road vehicles. They deliver strong braking for tough roads, heavy loads, and high-temperature conditions.

Brake Pad Factory

Our brake pad factory was established in 2009 in Wuhu, Anhui, covering 50,000 ㎡ and supported by a team of over 100 skilled workers. With more than 20 production lines and 3 fully equipped laboratories, we are able to guarantee not only fast and stable delivery times, but also consistent, reliable quality for every order.

Over the years, thanks to the trust of new customers and the continued support of long-term partners, we’ve grown into one of the leading brake pad manufacturers in China. We understand what distributors and wholesalers really care about — quality that passes the market test, prices that keep you competitive, and a production schedule you can count on.

We’re always here to support your business. Feel free to reach out anytime — we’d be glad to work with you and help you grow your market.

How We Produces OE-Quality Brake Pads?

Strong manufacturing. Reliable performance. Consistent quality.

Material Selection & Formula Control

We start with carefully selected raw materials — high-quality fibers, stable friction modifiers, and premium resin binders. Each batch is weighed according to a fixed formula to ensure consistent braking performance, low dust, and long service life.

Precision Mixing

All materials are placed into high-speed mixers where they are blended until fully uniform. Stable mixing ensures the friction material has the right density, balance, and structure before forming.

Backing Plate Treatment

Backing plates are cleaned, shot-blasted, and coated with adhesive to create a strong bonding surface. This step prevents rust and guarantees that the friction material stays firmly attached during heavy braking.

Molding & Pressing

We use hot molding for all our brake pads. The friction material is pressed under high temperature and high pressure, allowing it to form and pre-cure at the same time.

This process gives the pads stable density, strong bonding, and consistent braking performance.

High-Temperature Curing

Semi-finished pads are placed into large curing ovens, where they undergo several hours of controlled heating. This step enables the resin to harden fully, providing the brake pad with strong wear resistance and stable friction levels.

Scorching Treatment

After curing, the pad surface is rapidly heated to remove gases and improve initial braking performance. This treatment helps reduce noise and shortens the bedding-in period for drivers.

Grinding, Chamfering & Slotting

Each pad is precisely ground to meet thickness requirements. Our CNC machines add chamfers and slots to reduce noise, release dust, and improve heat dissipation. This ensures better comfort and less brake vibration.

Shim, Clips & Hardware Assembly

Noise-reducing shims, clips, and wear indicators are installed according to each model’s requirements. We also apply anti-corrosion coatings to the steel back plates for a cleaner appearance and longer service life.

Strict Quality Control

Before packaging, every batch goes through:

- Dimensional and thickness measurements

- Bonding strength checks

- Hardness and density tests

- Visual inspection for cracks, uneven surfaces, or burrs

Marking & Packaging

Our brake pads are cleaned, laser-marked, and packed in strong export cartons. We support OEM brand packaging, small-order customization, and container mixed loading to help our partners save costs.

Shipping & Delivery

After final inspection and packaging, all brake pads are safely loaded for shipment. We work closely with reliable freight forwarders to ensure on-time delivery, whether by sea, air, or express.

Send Inquiry Now

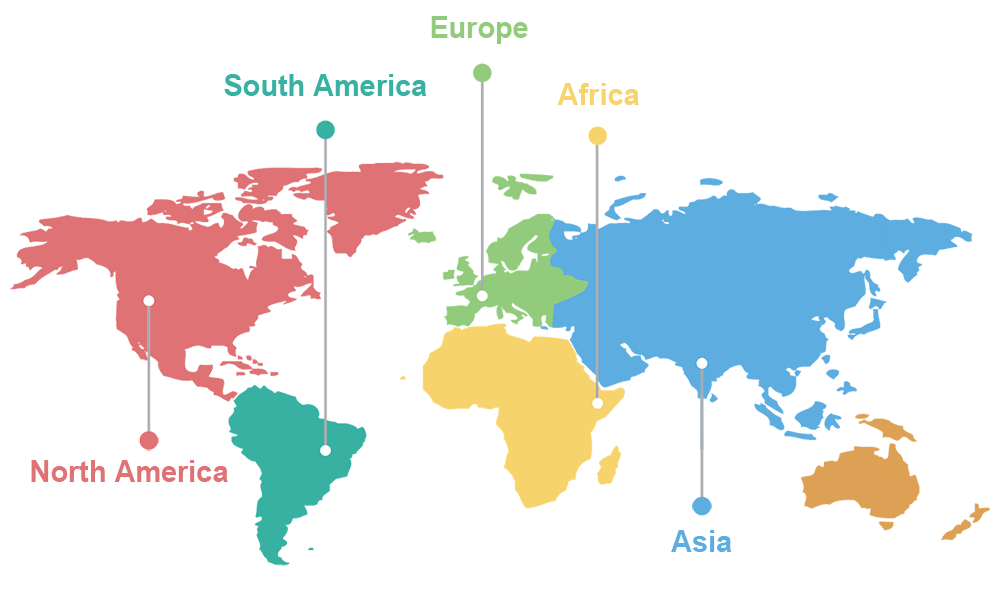

Our Main Markets

North America

America, Canada, Mexico, Guatemala, El Salvador, Honduras, Costa Rica, Panama

South America

Colombia, Venezuela, Suriname, Ecuador, Peru, Bolivia, Brazil, Argentina, Chile

Europe

Finland, Poland, UK, France, Malta, Spain, Portugal, Andorra, Sweden, Belarus, Monaco

Africa

Egypt, Libya, Sudan, Tunisia, Algeria, Morocco, Kenya, Tanzania, Uganda, Gabon, Burkina Faso, Nigeria, Cape Verde, Côte d’Ivoire, Ghana, Zambia, Angola, Zimbabwe, Malawi, South Africa, Madagascar

Asia

South Korea, Japan, Philippines, Vietnam, Laos, Cambodia, Myanmar, Thailand, Malaysia, Indonesia, Bangladesh, India, Pakistan, Sri Lanka, Iraq, Iran, Syria, Jordan, Lebanon, Israel, Palestine, Saudi Arabia, Bahrain, Qatar, Kuwait, United Arab Emirates, Oman, Yemen, Turkey

Why Choose Us?

As a brake pad factory with rich experience, we provide full support to help you grow your business with ease.

OE Quality

Make production according to OE standards

Competitive Price

Give you factory direct selling prices

Lower MOQ

100sets each model

OEM&ODM

Support do your customized brand package

Warranty

1 Year after you receive our products

Why Clients Leave Old Suppliers — And Choose Us Instead?

We understand your challenges, so we’ve built solutions for you

Challenges with Old Suppliers

- Difficult Communication With Suppliers

“They have a hard time understanding my requests, so I keep explaining repeatedly, and occasionally things go wrong because they don’t fully get what I mean.”

- Delivery Delays and Broken Promises

“Their production time was always too long, and they could never ship on time. I couldn’t restock fast enough, and my customers started buying from my competitors.”

- Receiving Low or Unstable Quality Products

“I often received customer complaints about the brake pads—noise, unusual smell, and sometimes even cracking after installation. That was really scary for me.”

- Poor After-Sales Support

“What bothered me the most was that every time an after-sales problem came up, they offered no real help. I was left alone to deal with angry customers, and it seriously hurt my reputation and my brand.”

Our Solution

- Good Communication

With rich service experience and a deep understanding of brake pads, we provide clear, professional support. We have served customers in over 100 countries, so language is never a barrier.

- Fast Delivery on Time

We produce around 200,000 sets each month, with a regular production time of 55 days. Thanks to our robust production capacity, you can rely on us to deliver your orders on time, every time.

- Only Produce OE Quality Products

From brake pad formulas to production, every step is done in-house under our careful supervision, ensuring our brake pad quality.

- Excellent After-Sales Service

If any issue occurs, we respond immediately and work with you to find a fair solution. Our goal is to make sure your business isn’t affected and that you feel fully supported, giving you peace of mind that we’re always here to back you up.

More Than A Supplier, Your Trusted Partner

Together with our clients, we build stronger markets through trust, quality, and long-term cooperation.

Each year, we attend Automechanika exhibitions in Las Vegas, Mexico, Dubai, Shanghai, and the Canton Fair to talk about how to grow your business together face to face.

We sincerely invite customers to visit our factory. Experiencing our production process, quality control, and team collaboration firsthand helps build trust and long-lasting confidence.

Our relationship with customers goes beyond supplier and purchaser; we are also close friends and partners, sharing everyday moments and discussing future opportunities together.

Frequently Asked Questions

Everything you want to know about working with us — answered here.

Are you a manufacturer or a trading company?

What is Your MOQ?

Do you offer customized packaging and branding?

What is your warranty policy?

What payment terms do you accept?

Contact Us

You can send us your inquiry lists, requirements, or suggestions using the following form. We will reach you asap.