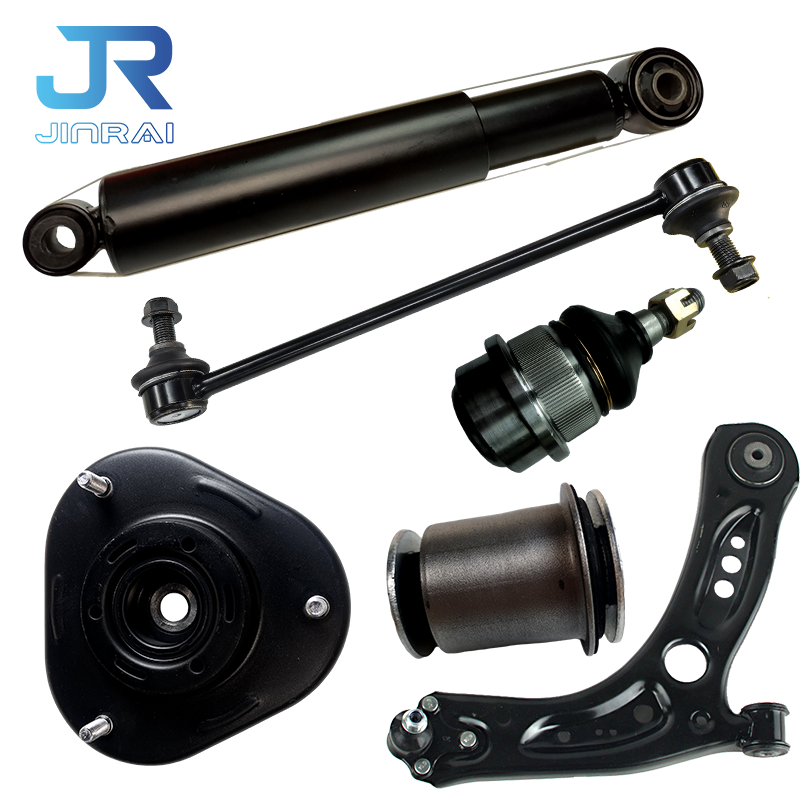

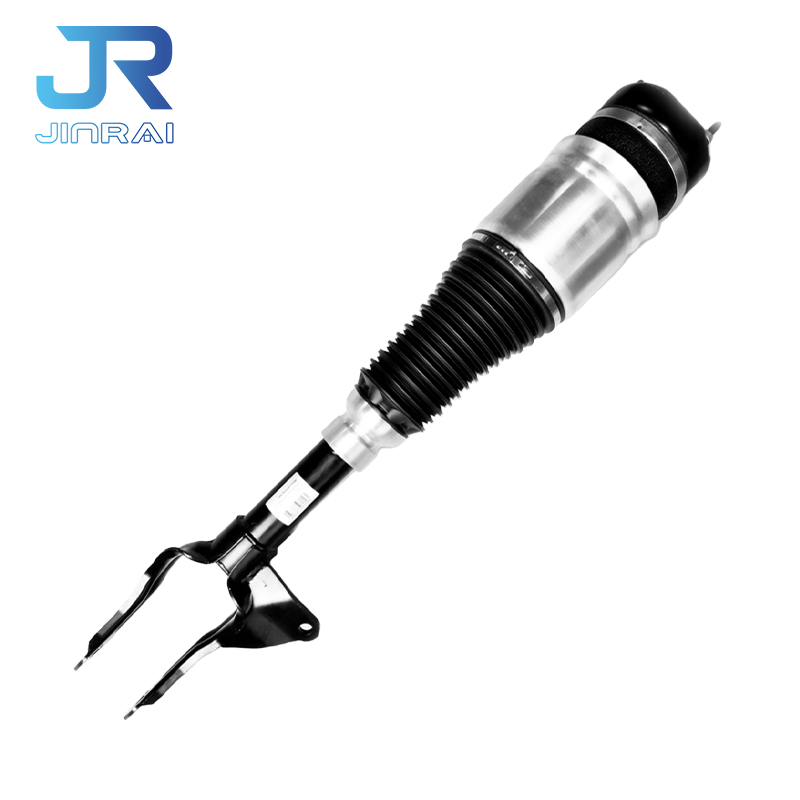

Shock Absorber Manufacturer in China

Anhui Goldenstar Auto Parts is a professional shock absorber manufacturer supplying the global automotive aftermarket with stable quality and competitive pricing. We specialize in automotive shock absorbers designed to deliver reliable damping performance, driving comfort, and long service life.

With over 20 years of factory experience, we produce front shock absorbers and rear shock absorbers for passenger cars, SUVs, pickup trucks, and light commercial vehicles. Our car shock absorbers cover Japanese, Korean, European, and American applications, supporting fast and efficient shock absorber replacement needs in different markets.

Our product range also includes truck shock absorbers, heavy duty shock absorbers, and hydraulic shock absorbers for commercial and high-load applications, providing complete suspension shock absorber solutions for the aftermarket.

As a reliable shock absorber supplier, we focus on aftermarket shock absorbers with services such as private label branding, customized packaging, flexible MOQs, and stable supply, helping you grow your suspension business with confidence.

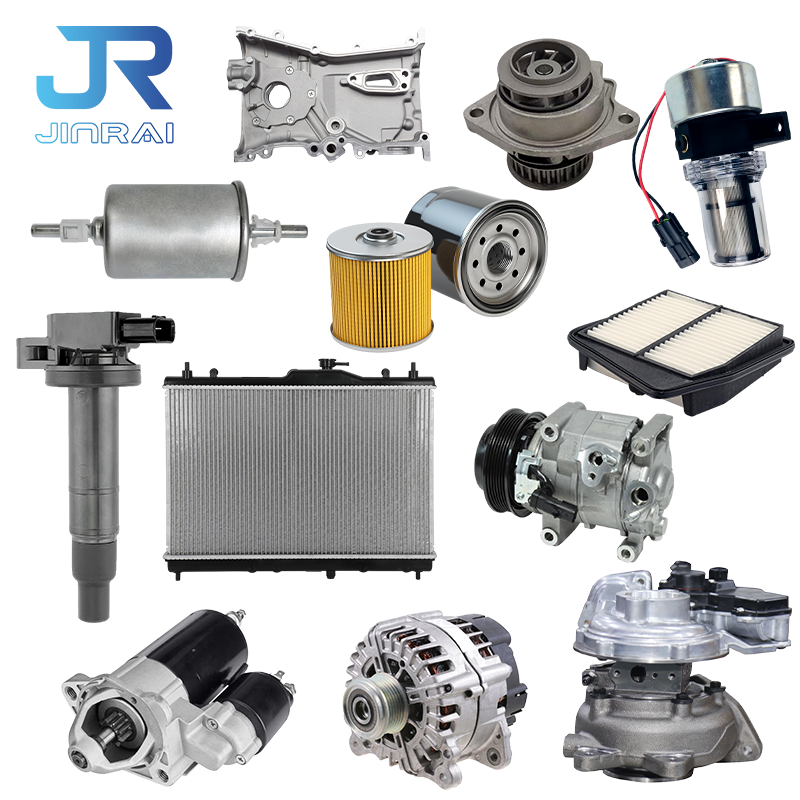

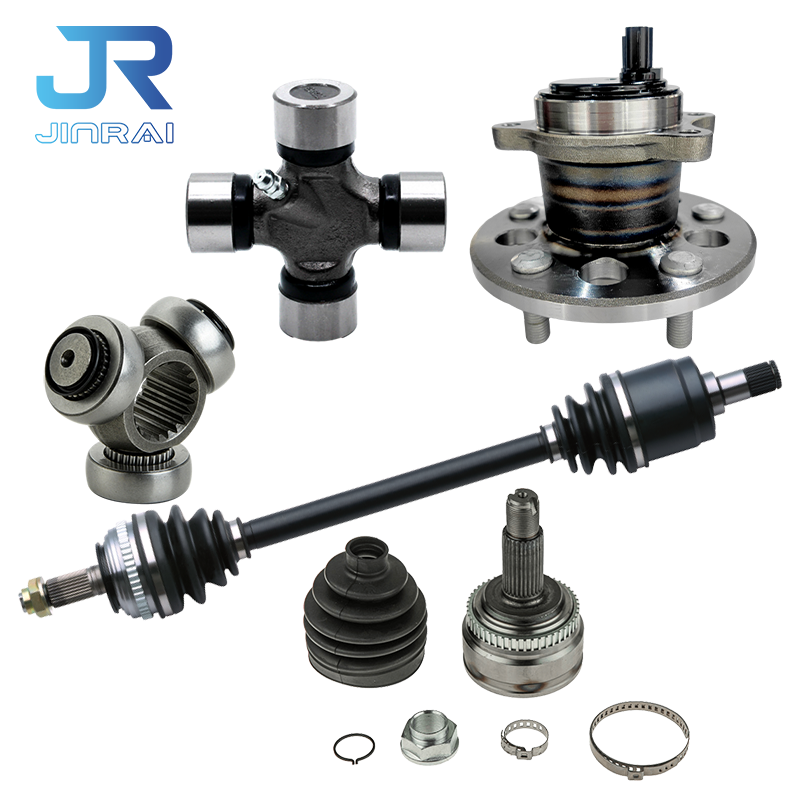

Our Shock Absorbers

A shock absorber is only as good as what it’s made of. That’s why we insist on high-quality materials in every piece we produce, delivering stronger durability, more stable damping, and fewer quality issues for our aftermarket partners.

- High-Strength Piston Rod

We use medium-carbon steel piston rods, finished with micro-crack hard chrome plating, to deliver strong wear resistance and reliable corrosion protection, ideal for long-term aftermarket use. - Sealed with Original NOK Oil Seals (Japan)

Equipped with genuine NOK oil seals, our shock absorbers are designed to minimize oil leakage and keep damping performance stable mile after mile. - Seamless Working Cylinder Construction

Our working cylinder is made from precision seamless steel tubing, providing better strength, smoother internal movement, and resistance to deformation. - Precisely Tuned Damping Valve System

Our optimized valve design ensures balanced compression and rebound force, helping vehicles stay stable while improving overall ride comfort. - Filled with NISSEKI Shock Absorber Oil

We use NISSEKI high-performance shock oil for its excellent anti-foaming properties and consistent damping performance across a wide temperature range.

Our Shock Absorber Application

What you need is exactly what we offer.

Japanese vehicles

Toyota, Honda, Nissan, Mazda, Subaru, Mitsubishi, Suzuki, Isuzu, Hino, Daihatsu

Korean Vehicles

Hyundai, Kia, Genesis, SsangYong

European Vehicles

DAF, Renault, Peugeot, Citroën, Fiat, Iveco, Volvo, Scania, Land Rover

American Vehicles

Ford, Chevrolet, Dodge, Tesla, Jeep, Cadillac, Buick

German Vehicles

Volkswagen, BMW, Audi, Porsche, Mercedes-Benz, MAN, Opel

FAQ of Shock Absorbers

what is a shock absorber?

A shock absorber is a key suspension component designed to control vehicle movement by reducing vibration, bounce, and impact from the road. A car shock absorber or truck shock absorber helps keep tires in contact with the road, improving stability, handling, and driving comfort. In the automotive aftermarket, shock absorbers are commonly replaced as part of regular suspension maintenance.

how long do shock absorbers last?

On average, aftermarket shock absorbers last between 50,000 and 100,000 kilometers, depending on driving conditions, vehicle load, and road quality. Heavy duty shock absorbers used in trucks or commercial vehicles may wear faster under high loads or rough roads. Regular inspection helps determine the right time for shock absorber replacement before performance declines.

how do shock absorbers work?

Automotive shock absorbers work by converting kinetic energy from suspension movement into heat energy, which is dissipated through hydraulic fluid. Inside most hydraulic shock absorbers, a piston moves through oil-filled chambers, controlling compression and rebound. This process limits excessive movement of the suspension, ensuring smoother handling and consistent performance in both front shock absorbers and rear shock absorbers.

signs of a bad shock absorber

- Excessive bouncing after bumps

- Reduced steering control or vehicle instability

- Uneven or accelerated tire wear

- Oil leakage from the shock body

- Longer braking distance

Worn shock absorbers can affect overall suspension balance, making timely replacement essential for safe driving and customer satisfaction.

Shock Absorber Factory

Founded in 2001, our shock absorber factory spans 50,000 m² and is equipped with dedicated facilities for stamped parts and piston rod production. With advanced production lines and complete testing equipment, we ensure every autombile shock absorber meets OE standards and support you stable supply with a monthly production capacity of 100,000 pcs . Our factory is certified with ISO 9001, IATF 16949, and CE, guaranteeing reliable performance and safety.

How We Produces OE-Quality Shock Absorbers?

Strong manufacturing. Reliable performance. Consistent quality.

Material Selection&& Tube Processing

We use high-strength alloy steel & seamless tubes to ensure cylinders maintain shape under high pressure.

- Precision cylinder production: Cold-drawn and ultrasonically inspected to ensure zero micro-cracks.

- Reinforced piston rods: treated with medium-frequency quenching to achieve HRC50-60 for exceptional fatigue resistance.

Core Piston Rod Technology

The piston rod determines the shock absorber’s response speed and smoothness.

- Multi-stage grinding: CNC grinding achieves a mirror-smooth surface with Ra≤0.05µm

- Micro-crack chrome plating: Stores lubrication film, reduces friction, and extends seal life.

Fully Automated Digital Welding

Strong welds are critical to vehicle safety.

- FANUC robotic welding: Ensures consistent, full, and pore-free welds on bases and spring seats.

- Penetration monitoring: Destructive testing on each batch ensures welds withstand extreme shear forces.

Clean Assembly Environment

- Multi-stage ultrasonic cleaning: Every component is thoroughly cleaned before assembly.

- High-purity nitrogen filling: 99.9% pure nitrogen prevents hydraulic oil foaming and ensures consistent damping.

- Premium seals: Imported NOK or equivalent multi-lip oil seals guarantee zero leakage from -40℃ to 120℃.

Advanced Surface Protection

Electrophoresis & powder coating: Eco-friendly corrosion-resistant coatings withstand 240–480 hours of salt spray tests, keeping every piece durable and visually flawless.

Rigorous 100% Performance Testing

We don’t rely on sampling; every piece is tested.

- Damping force testing: High- and low-speed performance is measured on computer-controlled test rigs with a strict ±5% tolerance.

- Durability testing: Simulated 5 million-cycle tests ensure long-term performance without loss of damping force.

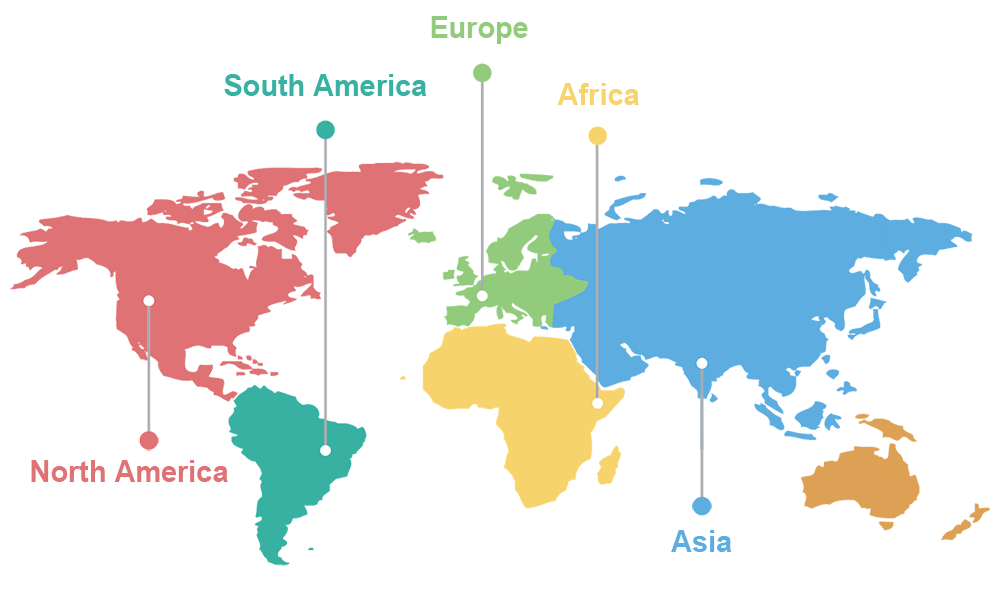

Our Main Markets

North America

America, Canada, Mexico, Guatemala, El Salvador, Honduras, Costa Rica, Panama

South America

Colombia, Venezuela, Suriname, Ecuador, Peru, Bolivia, Brazil, Argentina, Chile

Europe

Finland, Poland, UK, France, Malta, Spain, Portugal, Andorra, Sweden, Belarus, Monaco

Africa

Egypt, Libya, Sudan, Tunisia, Algeria, Morocco, Kenya, Tanzania, Uganda, Gabon, Burkina Faso, Nigeria, Cape Verde, Côte d’Ivoire, Ghana, Zambia, Angola, Zimbabwe, Malawi, South Africa, Madagascar

Asia

South Korea, Japan, Philippines, Vietnam, Laos, Cambodia, Myanmar, Thailand, Malaysia, Indonesia, Bangladesh, India, Pakistan, Sri Lanka, Iraq, Iran, Syria, Jordan, Lebanon, Israel, Palestine, Saudi Arabia, Bahrain, Qatar, Kuwait, United Arab Emirates, Oman, Yemen, Turkey

Why Choose Us?

As a shock absorber factory with rich experience, we provide full support to help you grow your business with ease.

OE Quality

Make production according to OE standards

Competitive Price

Give you factory direct selling prices

Lower MOQ

100pcs each model

OEM&ODM

Support do your customized brand package

Warranty

1 Year after you receive our products

Your challenge VS Our solution

We understand your challenges, so we’ve built solutions for you

Your Challenge

- Difficult Communication With Suppliers

“I frequently need to repeat my requests, yet many suppliers still respond unclearly or too slowly. Updates on orders are often missing, communication is inconsistent, and misunderstandings happen regularly, causing delays, mistakes, and wasted time on my end.”

- Delivery Delays and Broken Promises

“Delivery delays are a constant problem with my old supplier. The delivery date gets confirmed, I arrange my plans, and then right before shipment, it’s delayed again. This causes all kinds of trouble on my end, upset customers, rushed explanations, and damage to my reputation, even though I didn’t do anything wrong.”

- Receiving Low or Unstable Quality Products

“Some parts simply aren’t finished well enough. Poor sealing and rough machining have led to oil leakage after installation. Once that happens, customers come back with complaints, request returns or refunds, and I have to cover the cost, even though the problem started with manufacturing quality.”

- Poor After-Sales Support

“When problems happened, it felt like my supplier disappeared. I kept chasing replies, but nothing moved forward. In the end, I took the loss, dealt with customer complaints, and tried to protect my reputation on my own.”

Our Solution

- Good Communication

We’ve worked with customers in over 100 countries, so we know how to keep communication simple and clear. You get direct answers, practical advice, and quick responses, without chasing or misunderstandings.

- Fast Delivery on Time

Producing roughly 100,000 pieces each month with a strict 55-day lead time, we make sure your orders arrive on time, every time. Our production capacity and planning discipline give you confidence and peace of mind in your supply chain.

- Only Produce OE Quality Products

All production, from casting and machining to final assembly, is carried out in-house under strict quality control. Every shock absorber is individually tested before shipment, giving you confidence that it meets OE standards and performs consistently.

- Excellent After-Sales Service

We offer a one-year warranty and lifetime after-sales support. If any quality issue comes up, we take full responsibility; you won’t have to bear any loss. Our team is always ready to step in, answer your questions, and fix any issues quickly, so you can focus on your business without worrying.

More Than A Supplier, Your Trusted Partner

Together with our clients, we build stronger markets through trust, quality, and long-term cooperation.

Each year, we take part in top automotive exhibitions across the globe — from Las Vegas and Mexico to Dubai, Shanghai, and the Canton Fair. It’s a great way for us to show our products, meet customers face-to-face, and keep up with what the international market really needs.

Customers are always welcome to come by our factory. Watching our production lines, quality checks, and teamwork up close lets you see exactly what we can do and helps build trust for a long-term relationship.

To us, our customers aren’t just clients. We share ideas, meals, and experiences together, learning and growing as we go. That way, we really understand what they need, offer better solutions, and build partnerships that feel more like friendship than business.

Frequently Asked Questions

Everything you want to know about working with us — answered here.

Are you a manufacturer or a trading company?

What is Your MOQ?

Do you offer customized packaging and branding?

What is your warranty policy?

What payment terms do you accept?

Contact Us

You can send us your inquiry lists, requirements, or suggestions using the following form. We will reach you asap.