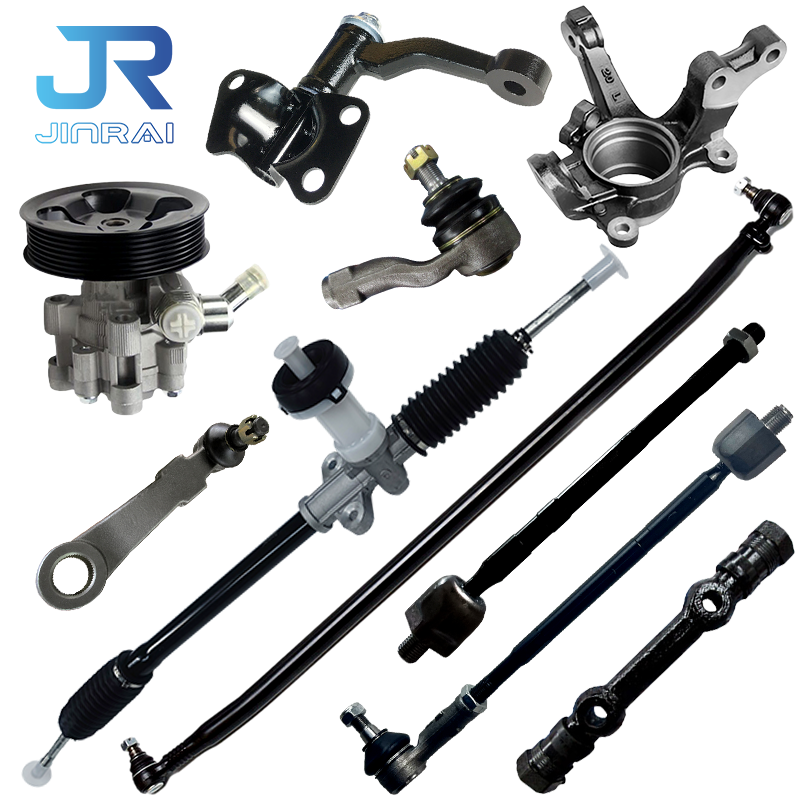

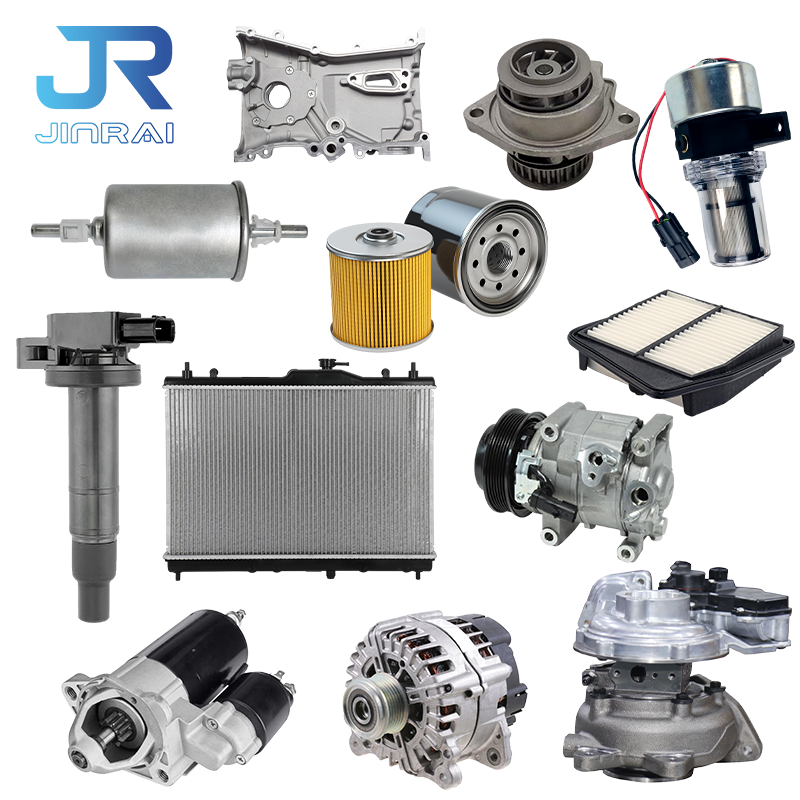

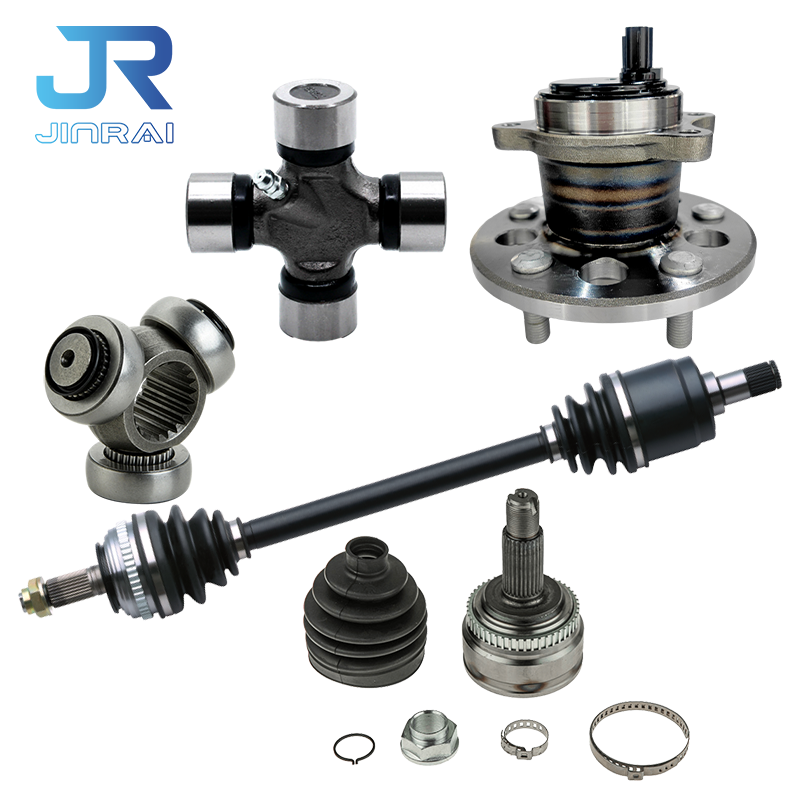

Wholesale Rack End Manufacturer

Factory Prices | OE Quality | Customization Service

Rack End Manufacturer in China

Anhui Goldenstar Auto Parts is a professional rack end manufacturer with over 20 years of experience in producing steering system components for the global automotive aftermarket. As a direct rack end factory, we focus on delivering OE-quality rack ends with stable performance, precise fitment, and long service life, helping aftermarket brands and distributors build reliable steering product lines.

As an experienced rack end supplier, we offer a comprehensive range of rack end models covering Japanese, Korean, European, American, and Chinese vehicles. Our product catalog supports passenger cars, light trucks, commercial vehicles, and heavy-duty applications. With thousands of rack end references available, we help our partners avoid lost sales caused by limited coverage or slow model development.

Beyond manufacturing, we support aftermarket brand growth through customized branding services. As a full-service rack end factory, we provide customization options including laser marking, brand labels, color bags, inner boxes, and outer cartons, helping our partners strengthen brand recognition while maintaining competitive pricing.

If you are searching for a reliable rack end manufacturer, Anhui Goldenstar Auto Parts is ready to support your business. Contact us today to discuss your rack end requirements and explore stable, long-term cooperation.

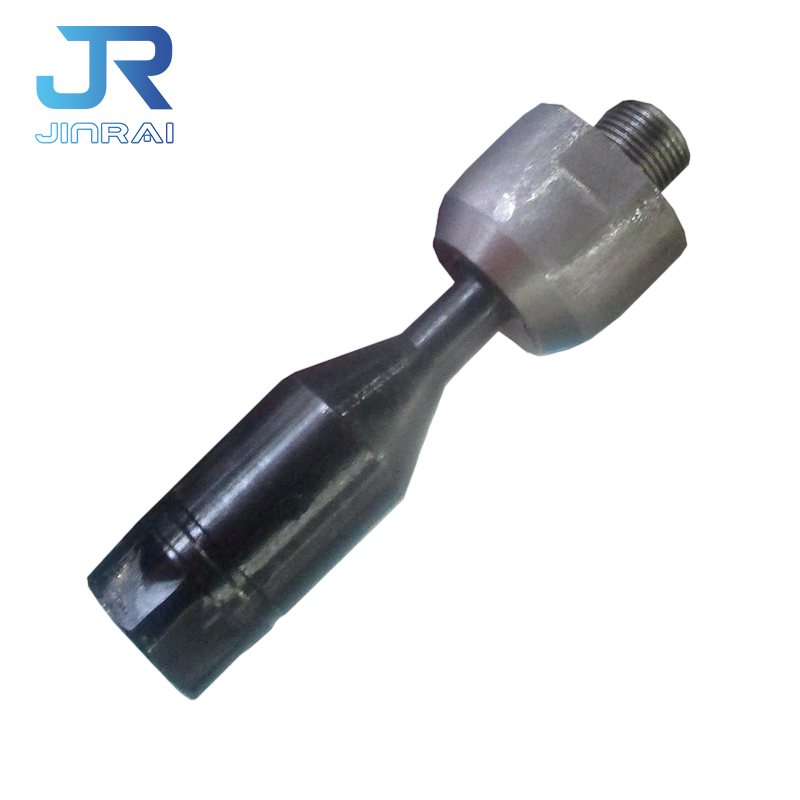

Our Rack Ends Advantages

- Accurate Thread & Perfect Fit

Precisely machined threads ensure correct fitment with steering racks, making installation easy and reducing looseness after installation. - High-Strength Forged Housing

Forged steel construction improves resistance to impact and deformation, ensuring durability under rough roads and heavy-use conditions. - Hardened Ball Stud

Heat-treated ball studs provide strong wear resistance, maintaining smooth movement and extending service life. - Smooth Steering Response

Controlled internal clearances deliver stable, responsive steering with minimal play during operation. - Durable Dust Boot & Sealing

Oil- and tear-resistant dust boots protect internal components from dust and water, extending product lifespan.

Our Rack Ends Application

What you need is exactly what we offer.

Japanese vehicles

Toyota, Honda, Nissan, Mazda, Subaru, Mitsubishi, Suzuki, Isuzu, Hino, Daihatsu

Korean Vehicles

Hyundai, Kia, Genesis, SsangYong

European Vehicles

DAF, Renault, Peugeot, Citroën, Fiat, Iveco, Volvo, Scania, Land Rover

American Vehicles

Ford, Chevrolet, Dodge, Tesla, Jeep, Cadillac, Buick

German Vehicles

Volkswagen, BMW, Audi, Porsche, Mercedes-Benz, MAN, Opel

FAQ of Rack Ends

What is a Rack End?

A rack end, also known as a inner tie rod end, is a key component of the vehicle’s steering system. It connects the steering rack to the steering knuckle, allowing the wheels to turn according to the driver’s input. Rack ends are essential for precise steering control and safe vehicle handling. High-quality rack ends ensure smooth steering operation and long-term reliability.

How Long Does a Rack End Last?

The lifespan of a rack end depends on driving conditions, road quality, and maintenance, but a standard rack end can last 50,000 to 100,000 km under normal driving conditions. Harsh roads, heavy loads, or lack of protective maintenance (like damaged dust boots) can shorten service life. Replacing worn rack ends on time helps prevent steering problems and uneven tire wear.

What Does a Rack End Do?

A rack end translates the steering rack’s movement into wheel movement. It ensures:

- Smooth steering response

- Accurate wheel alignment

- Proper suspension geometry

By maintaining a stable connection between the steering rack and wheels, a healthy rack end contributes to safe handling and predictable vehicle performance.

Bad Rack End Symptoms

A worn or damaged rack end can affect safety and handling. Common signs include:

- Loose or sloppy steering: excessive play in the steering wheel

- Uneven tire wear: caused by misalignment due to loose rack ends

- Clunking or knocking noises: when turning or driving over bumps

- Steering pull: vehicle drifts to one side when driving straight

- Vibration in the steering wheel: noticeable at higher speeds

Early detection and replacement of faulty rack ends prevent more serious steering or suspension damage and ensure driving safety.

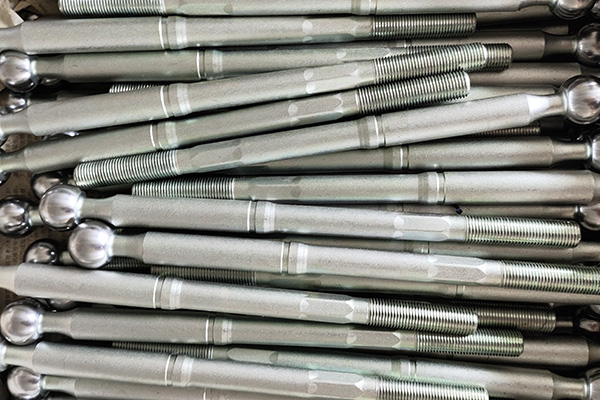

Rack End Factory

Founded in 2005, our rack end factory spans over 120,000 m² and is backed by more than 500 skilled professionals dedicated to producing high-quality steering components.

We run a fully integrated, in-house production system, featuring forging lines, CNC machining centers, stamping and laser cutting lines, robotic welding systems, automated assembly lines, and precision finishing processes. This complete control over every step from raw material to finished rack end ensures consistent quality and reliable performance in every product.

By managing all key production processes internally, we maintain strict quality standards across all batches. With a monthly production capacity of 300,000 rack ends, we can reliably meet large-volume orders while keeping lead times consistent.

Our end-to-end manufacturing capability allows us to provide stable, OE-quality rack ends, support long-term supply agreements, and help our clients grow their aftermarket and distribution businesses with confidence.

Production Process of OE-Quality Rack Ends

Strong manufacturing. Reliable performance. Consistent quality.

Material Preparation

High-strength steel is carefully chosen for each rack end. Incoming materials undergo strict quality checks to ensure durability, toughness, and consistency.

Forging Key Components

The ball stud and housing are forged to achieve optimal density and structural strength, providing resistance to impact, deformation, and long-term wear.

Precision Machining

Forged components are CNC-machined to precise dimensions, ensuring perfect thread accuracy, proper fitment, and smooth movement for steering performance.

Heat Treatment

Critical parts, including the ball stud, undergo controlled heat treatment to achieve hardness and wear resistance, ensuring long service life under different road conditions.

Surface Finishing & Coating

Rack ends receive corrosion-resistant surface treatments or color coatings based on market preferences, protecting components from rust and enhancing appearance.

Assembly & Lubrication

The ball stud is assembled into the housing with high-quality grease applied to minimize friction and allow smooth articulation throughout its service life.

Quality Checks

Every rack end undergoes rigorous inspection, including dimensional checks, load testing, and visual verification, ensuring that only products meeting strict standards move forward.

Packaging & Delivery

Rack Ends are packed according to customer needs, including:

- Neutral packaging

- Customized brand packaging

- Barcode and labeling support

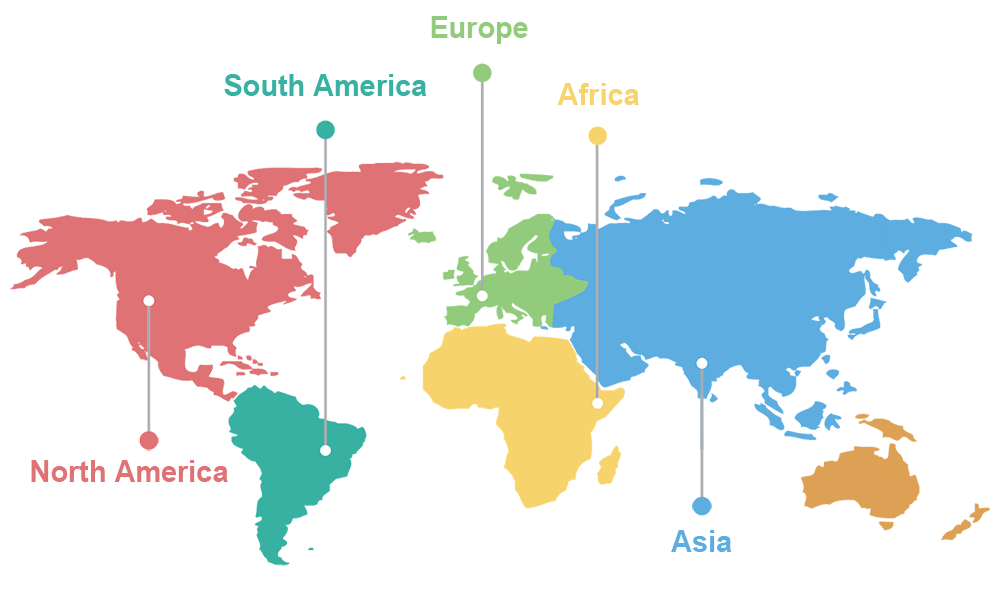

Our Main Markets

North America

America, Canada, Mexico, Guatemala, El Salvador, Honduras, Costa Rica, Panama

South America

Colombia, Venezuela, Suriname, Ecuador, Peru, Bolivia, Brazil, Argentina, Chile

Europe

Finland, Poland, UK, France, Malta, Spain, Portugal, Andorra, Sweden, Belarus, Monaco

Africa

Egypt, Libya, Sudan, Tunisia, Algeria, Morocco, Kenya, Tanzania, Uganda, Gabon, Burkina Faso, Nigeria, Cape Verde, Côte d’Ivoire, Ghana, Zambia, Angola, Zimbabwe, Malawi, South Africa, Madagascar

Asia

South Korea, Japan, Philippines, Vietnam, Laos, Cambodia, Myanmar, Thailand, Malaysia, Indonesia, Bangladesh, India, Pakistan, Sri Lanka, Iraq, Iran, Syria, Jordan, Lebanon, Israel, Palestine, Saudi Arabia, Bahrain, Qatar, Kuwait, United Arab Emirates, Oman, Yemen, Turkey

Why Choose Us?

As a rack end factory with rich experience, we provide full support to help you grow your business with ease.

OE Quality

Make production according to OE standards

Competitive Price

Give you factory direct selling prices

Lower MOQ

120pcs each model

OEM&ODM

Support do your customized brand package

Warranty

1 Year after you receive our products

Your challenge VS Our solution

We focus on solving these problems before they become your problems.

Your Challenge with other suppliers

- Difficult Communication

“I’ve shared my requirements multiple times, yet I still receive unclear answers or delayed responses, forcing me to repeat myself over and over.”

- Delivery Delays and Broken Promises

“The delivery date initially seemed acceptable, but it keeps being postponed with varying reasons each time.”

- Receiving Low or Unstable Quality Products

“The sample looked acceptable and met my expectations, but when I received the bulk order, the quality and details felt completely different.”

- Poor After-Sales Support

”When problems surface afterward, communication suddenly slows down, messages go unanswered, and clear solutions are hard to get.”

Our Solution

- Good Communication

Serving 800+ customers has taught us one thing: clear communication prevents problems. We make sure everything is confirmed before production, and we stay responsive long after it starts.

- Fast Delivery on Time

Because all key processes are handled in-house, our capacity is predictable. That allows us to give achievable lead times and deliver exactly as promised.

- Only Produce OE Quality Products

By keeping every production stage in-house, we ensure consistent quality and nothing leaves our factory without a complete final inspection.

- Excellent After-Sales Service

Delivery is not the finish line for us. We take ownership of post-delivery issues and respond promptly because we value long-term collaboration over one-off orders.

More Than A Supplier, Your Trusted Partner

Let’s work together — your success is our mission.

Across major automotive exhibitions worldwide, we meet our customers in person, exchange insights, and keep pace with evolving market demands, turning conversations into stronger partnerships.

We encourage customers to visit our factory and see how things are actually made, from production flow to quality control. Transparency builds trust, and we have nothing to hide.

We see our customers as long-term partners. Through open communication and collaborative problem-solving, we build trust, understand your business, and support your growth in the market.

Frequently Asked Questions

Everything you want to know about working with us — answered here.

Are you a manufacturer or a trading company?

What is Your MOQ?

Do you offer customized packaging and branding?

What is your warranty policy?

What payment terms do you accept?

Contact Us

You can send us your inquiry lists, requirements, or suggestions using the following form. We will reach you asap.