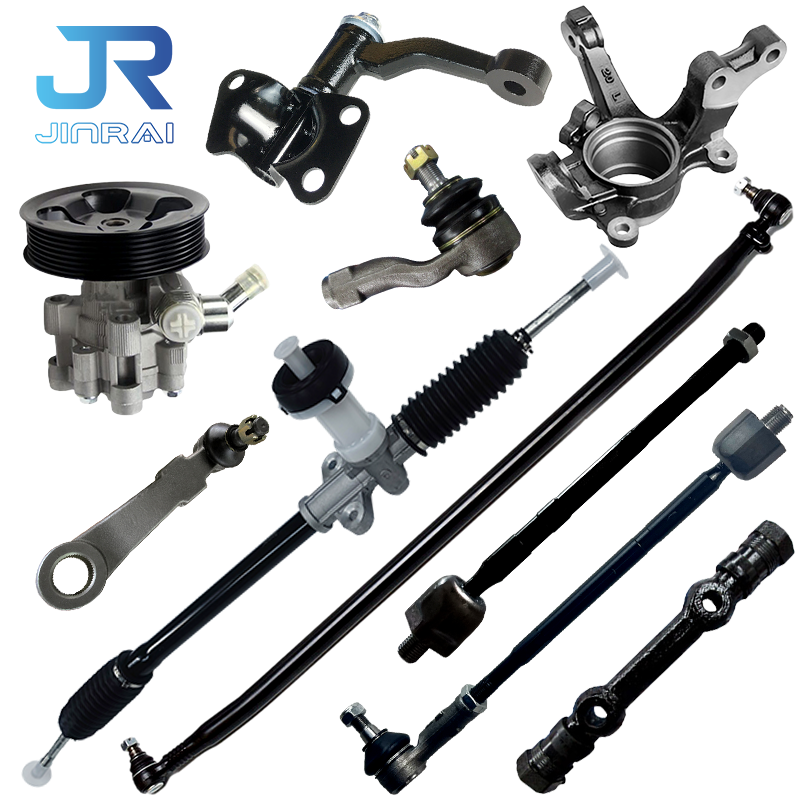

Wholesale Ball Joint Manufacturer

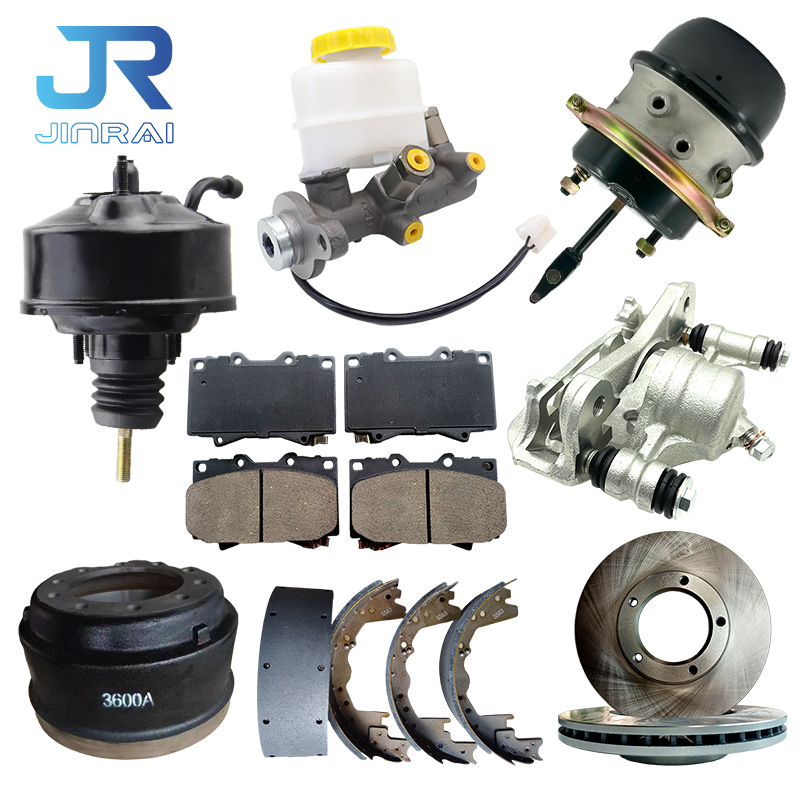

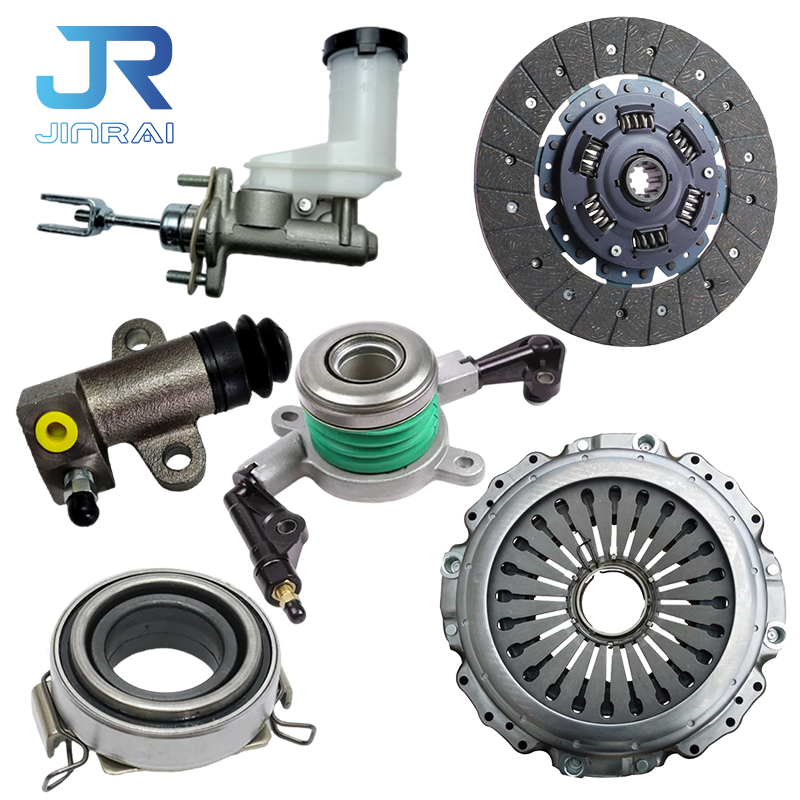

Factory Prices | OE Quality | Customization Service

Ball Joint Manufacturer in China

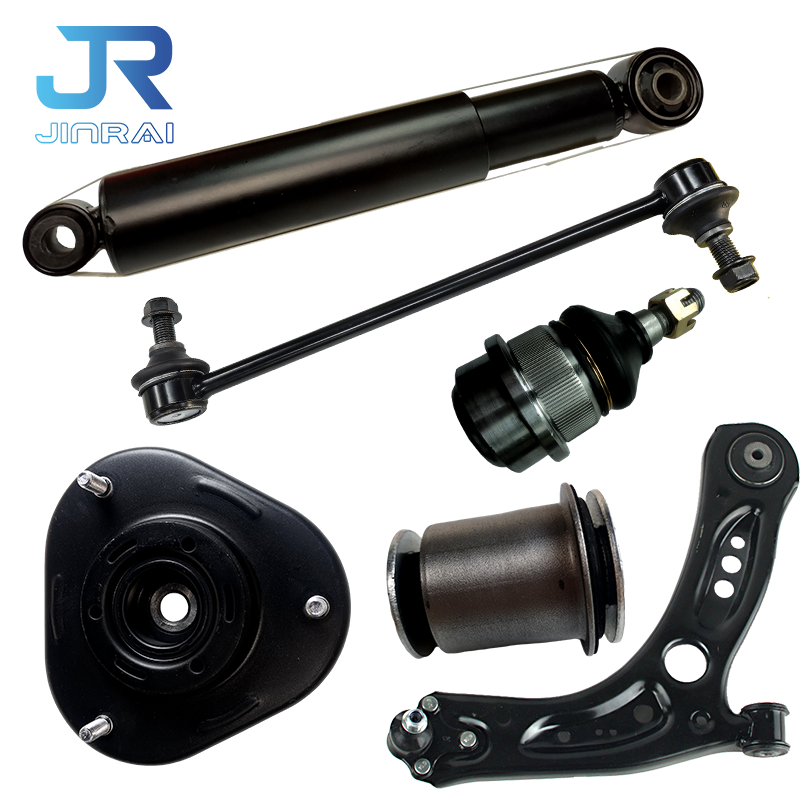

Anhui Goldenstar Auto Parts is a professional ball joint manufacturer with over 20 years of experience in producing suspension and steering components. As a trusted ball joint factory, we focus on delivering OE-quality products for global automotive aftermarket brands, helping our partners build reliable product lines and long-term market confidence.

With over 2,000 ball joint models in our range, we cover Japanese, Korean, European, American, and Chinese vehicles, including passenger cars, light trucks, medium- and heavy-duty trucks, and commercial vehicles. Backed by our strong R&D and tooling team, we can support both fast-moving and hard-to-find ball joint replacement parts, ensuring our customers never miss market opportunities due to limited model coverage.

Beyond product range, we understand the importance of brand differentiation in the aftermarket. As an experienced ball joint supplier, we offer full customization services to support private-label and branded projects. From laser marking and logo printing on products to brand labels, color poly bags, inner boxes, and outer cartons, every detail can be customized to strengthen your brand presence in your target market.

If you are looking for a reliable ball joint manufacturer who can give you high-quality, competitive pricing, responsive after-sales support, and flexible customization, Anhui Goldenstar Auto Parts is ready to support your business. Feel free to contact us to discuss your requirements and explore long-term cooperation.

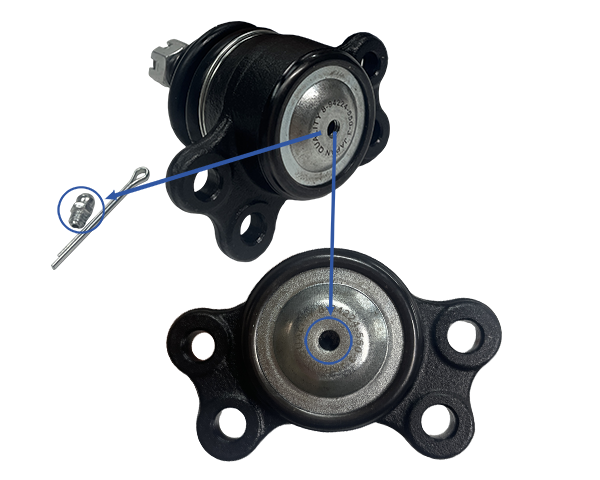

Our Ball Joints Advantages

- High-Strength Forged Ball Stud

Made from quality steel, offering excellent strength and impact resistance without deformation. - Precision Machined Ball Surface

Tight tolerances ensure smooth rotation, stable steering performance, and reduced noise. - Durable Wear-Resistant Bearing

High-quality internal bearing material minimizes friction and extends service life. - Reliable Dust Boot Sealing

Premium rubber dust boot effectively blocks dirt and moisture under harsh road conditions. - Stable Structural Design

Well-engineered assembly ensures secure fitment and lowers the risk of premature failure.

Our Ball Joints Application

What you need is exactly what we offer.

Japanese vehicles

Toyota, Honda, Nissan, Mazda, Subaru, Mitsubishi, Suzuki, Isuzu, Hino, Daihatsu

Korean Vehicles

Hyundai, Kia, Genesis, SsangYong

European Vehicles

DAF, Renault, Peugeot, Citroën, Fiat, Iveco, Volvo, Scania, Land Rover

American Vehicles

Ford, Chevrolet, Dodge, Tesla, Jeep, Cadillac, Buick

German Vehicles

Volkswagen, BMW, Audi, Porsche, Mercedes-Benz, MAN, Opel

Ball Joint Ordering Notes

Details should be confirmed with our sales team before purchase

Surface Finish & Color

We offer multiple surface finish options to meet different market preferences. According to our experience, customers in South America prefer black color, and clients in North Africa widely accept black or silver color.

Natural Color

Black Color

Silver Color

Ball Joint Grease Nipple Design

Ball joints are available in different structural designs. Different markets have different design preferences. Design selection should be confirmed in advance.

Ball Joint With grease nipple

Advantages:

- Allows regular lubrication, helping reduce friction and wear

- Service life can be extended under heavy load or harsh road conditions

- Preferred in markets where routine maintenance is common

Disadvantages:

- Requires periodic greasing during service

- Improper lubrication may lead to contamination or uneven performance

Ball Joint Without grease nipple

Advantages:

- Maintenance-free design, no lubrication required

- Cleaner structure with lower risk of dirt or water ingress

- Suitable for users who prefer simple installation and minimal maintenance

Disadvantages:

- Cannot be re-lubricated once internal grease is depleted

- Service life depends heavily on initial grease quality and sealing performance

Thread Stud & Accessories Assemble

The assembly method can be adjusted according to your installation process and logistics requirements.

Pre-assembled on the ball joint

- Bolts, nuts, and related accessories are installed in advance

- Reduces installation steps and improves assembly efficiency

- Due to the irregular shape, this option occupies more packing volume

Separately packed

- Ball joint and accessories are separate in bags

- More compact packing structure, helping save space and reduce shipping volume

- Suitable for buyers who focus on container optimization and logistics efficiency

Twist Force

The video shows the ball joint with standard twist force, which is suitable for most common applications. If a higher tightening torque is required, please inform us before placing your order. The torque requirement will be clearly noted in the order for production confirmation.

Ball Joint Factory

Established in 2005, our ball joint manufacturing facility covers over 120,000 m² and is supported by a workforce of 500+ skilled workers.

We operate a fully in-house production system, including a forging production line, laser cutting line, stamping line, robotic automatic welding line, machining center production line, automated assembly line, rubber injection molding, and vulcanization lines.

From raw material processing to final assembly, all key production processes are completed within our own factory, ensuring consistent quality control at every stage.

With a monthly output of 300,000 ball joints, we maintain stable quality while reliably fulfilling bulk orders on time. Our integrated manufacturing capability allows us to deliver quality products and support long-term cooperation with all clients.

How We Produces OE-Quality Ball Joints?

Strong manufacturing. Reliable performance. Consistent quality.

Material Preparation

We start by selecting suitable steel materials that meet our strength and durability requirements, laying a solid foundation for long service life.

Forging Key Components

The ball stud and housing are forged in-house to form a dense structure, giving the ball joint the strength it needs to handle real road loads.

Precision Machining

After forging, we machine key areas using CNC equipment, keeping tolerances tight so the ball joint moves smoothly without unwanted play.

Heat Treatment & Finishing

We apply heat treatment to improve wear resistance, then finish the surface based on the confirmed specification and market requirements.

Dust Boot & Sealing

Dust boots and seals are produced in our own rubber molding lines, helping protect the internal structure from dirt, water, and moisture.

Assembly

Assembly is completed on automated lines. Torque levels and design options, such as grease nipple or sealed type, are applied according to the order.

Quality Checks

We have a complete laboratory system from raw material testing to whole-component fatigue testing, strictly adhering to the IATF16949 quality management system.

Packaging & Delivery

Ball joints are packed according to customer needs, including:

- Neutral packaging

- Customized brand packaging

- Barcode and labeling support

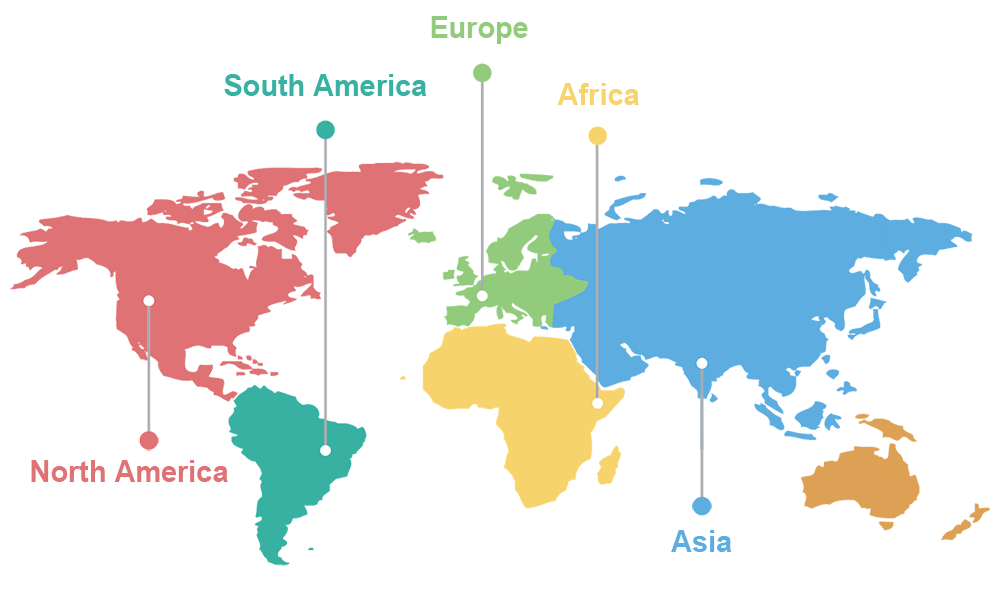

Our Main Markets

North America

America, Canada, Mexico, Guatemala, El Salvador, Honduras, Costa Rica, Panama

South America

Colombia, Venezuela, Suriname, Ecuador, Peru, Bolivia, Brazil, Argentina, Chile

Europe

Finland, Poland, UK, France, Malta, Spain, Portugal, Andorra, Sweden, Belarus, Monaco

Africa

Egypt, Libya, Sudan, Tunisia, Algeria, Morocco, Kenya, Tanzania, Uganda, Gabon, Burkina Faso, Nigeria, Cape Verde, Côte d’Ivoire, Ghana, Zambia, Angola, Zimbabwe, Malawi, South Africa, Madagascar

Asia

South Korea, Japan, Philippines, Vietnam, Laos, Cambodia, Myanmar, Thailand, Malaysia, Indonesia, Bangladesh, India, Pakistan, Sri Lanka, Iraq, Iran, Syria, Jordan, Lebanon, Israel, Palestine, Saudi Arabia, Bahrain, Qatar, Kuwait, United Arab Emirates, Oman, Yemen, Turkey

Why Choose Us?

As a ball joint factory with rich experience, we provide full support to help you grow your business with ease.

OE Quality

Make production according to OE standards

Competitive Price

Give you factory direct selling prices

Lower MOQ

120pcs each model

OEM&ODM

Support do your customized brand package

Warranty

1 Year after you receive our products

Your challenge VS Our solution

We focus on solving these problems before they become your problems.

Your Challenge with other suppliers

- Difficult Communication

“I’ve already explained my requirements, but I still get vague answers or very late replies. I end up repeating the same things again and again.”

- Delivery Delays and Broken Promises

“The delivery date sounds fine at first, then it keeps getting pushed back with different explanations.”

- Receiving Low or Unstable Quality Products

“The sample looks acceptable, but the bulk order feels completely different.”

- Poor After-Sales Support

“Once the goods are delivered, responses become slow or unclear when issues come up.”

Our Solution

- Good Communication

With experience of serving 800+clients, we confirm details clearly before production and keep communication smooth.

- Fast Delivery on Time

With full in-house production and stable capacity, we offer realistic delivery schedules and stick to what we confirm.

- Only Produce OE Quality Products

We control every production step in our own factory and 100% quality check before delivery.

- Excellent After-Sales Service

We respond quickly and take responsibility after delivery, focusing on long-term cooperation rather than one-time deals.

More Than A Supplier, Your Trusted Partner

Let’s work together — your success is our mission.

From Automechanika Las Vegas, Mexico, Dubai, Shanghai, to the Canton Fair, we keep in touch with the latest market trends, and meet clients face-to-face, building stronger connections and understanding your needs better.

We warmly invite our customers to visit our factory anytime. Seeing our production lines, quality control processes, and in-house capabilities helps you feel confident in the products you order and in our reliability.

We treat our customers like friends and long-term partners. From daily communication to solving challenges together, we focus on building trust, understanding your business, and helping you succeed in the market.

Frequently Asked Questions

Everything you want to know about working with us — answered here.

Are you a manufacturer or a trading company?

What is Your MOQ?

Do you offer customized packaging and branding?

What is your warranty policy?

What payment terms do you accept?

Contact Us

You can send us your inquiry lists, requirements, or suggestions using the following form. We will reach you asap.