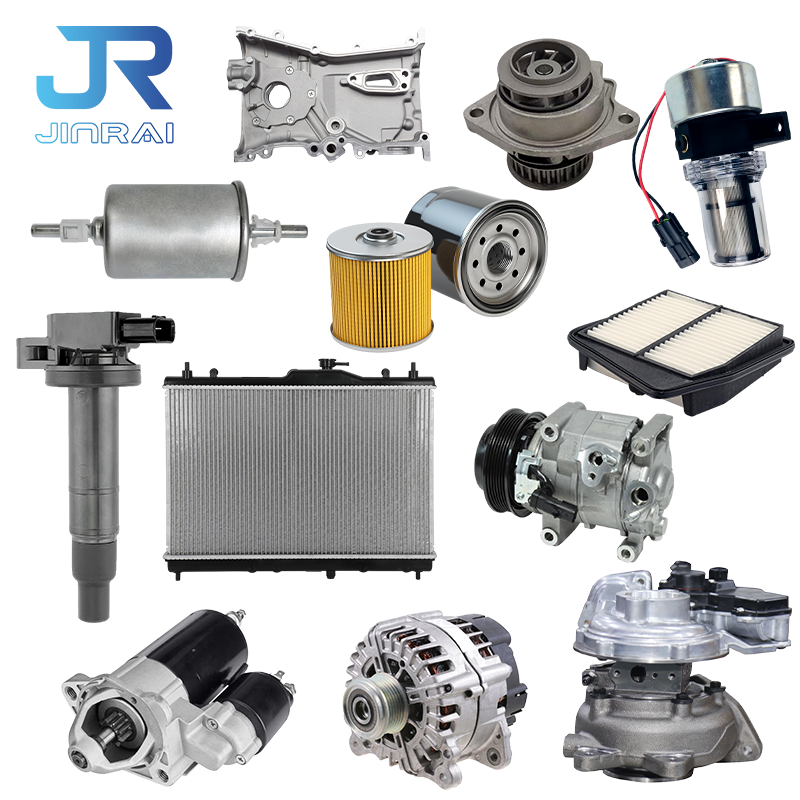

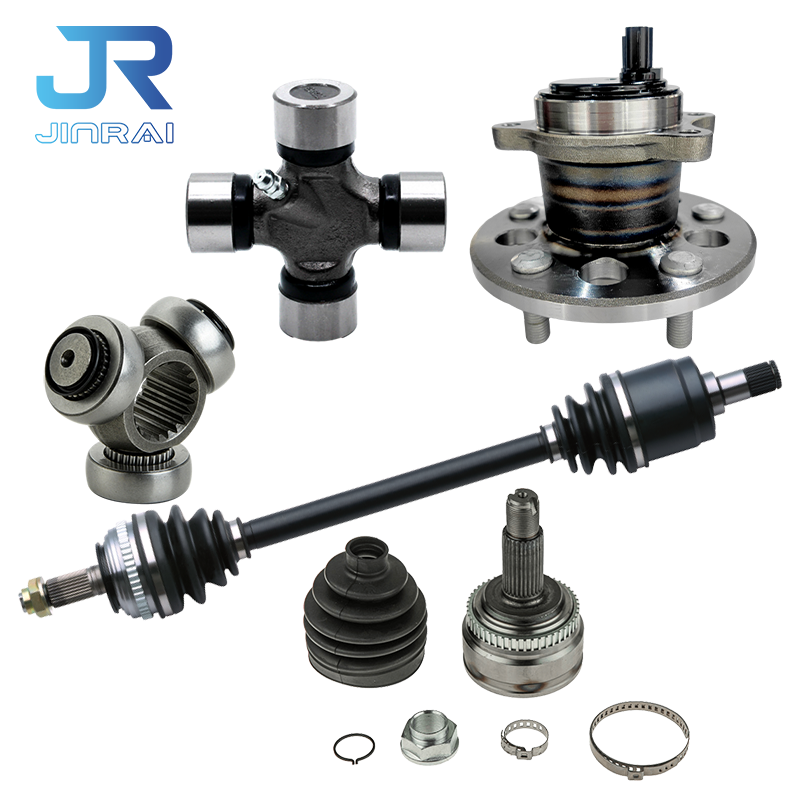

Wholesale Brake Caliper Manufacturer

We offer OE-quality brake calipers with factory prices, helping you increase profits and win your local market.

Brake Caliper Manufacturer in China

As a professional brake caliper manufacturer, Anhui Goldenstar Auto Parts is dedicated to delivering high-quality brake caliper replacements to the global aftermarket. With strong production experience and consistent quality control, we provide durable, OE-standard brake calipers that help our partners grow their business with confidence.

Our brake calipers cover European, American, Japanese, and Korean vehicles such as Iveco, Land Rover, BMW, Chrysler, Fiat, Ford, GM, Honda, Hyundai, Opel, Vauxhall, Toyota, Mazda, Nissan, Mitsubishi, Volvo, Mercedes-Benz, Audi, VW, Renault, Kia, and many more, if you need a brake caliper, we most likely have it.

In addition to our wide range, we also support custom brake calipers based on your samples. Thanks to our strong R&D and manufacturing capabilities, more and more customers choose us to meet their market demands quickly and with stable quality.

If you’re looking for a reliable brake caliper supplier who understands your needs and helps grow your market, feel free to contact us. We’re here to support your success.

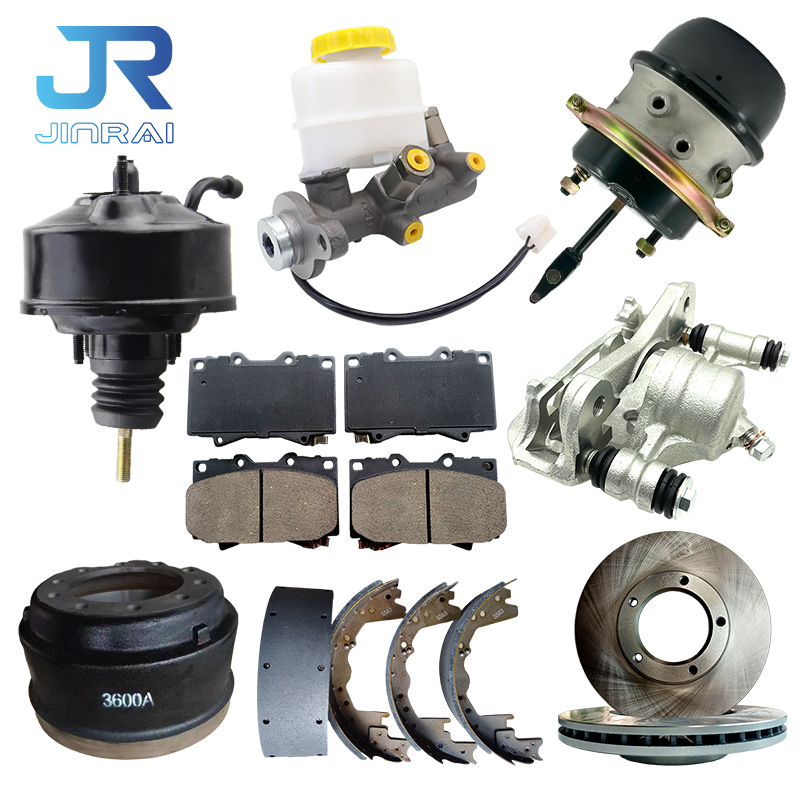

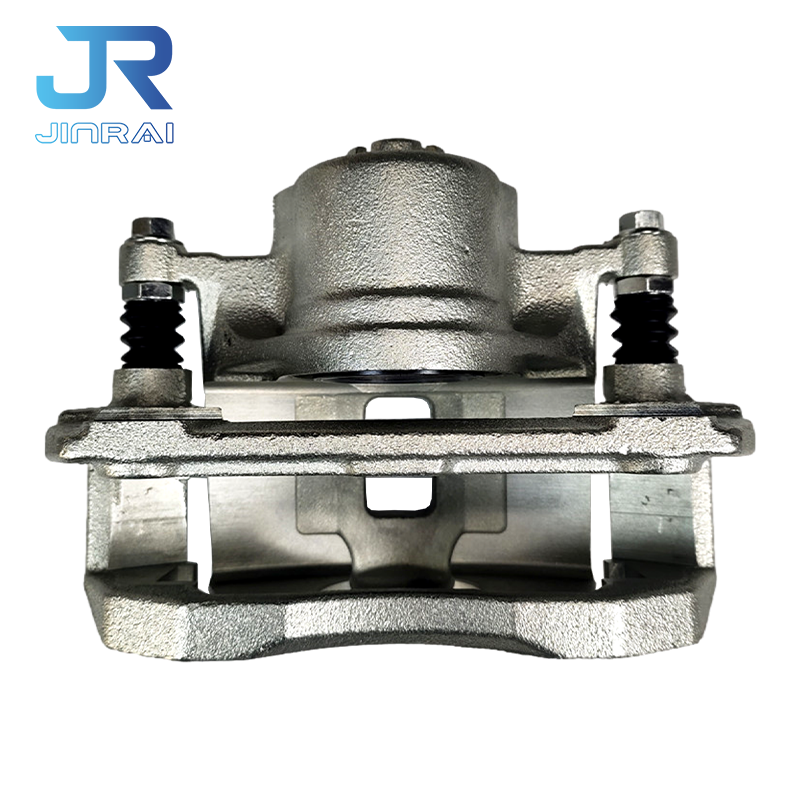

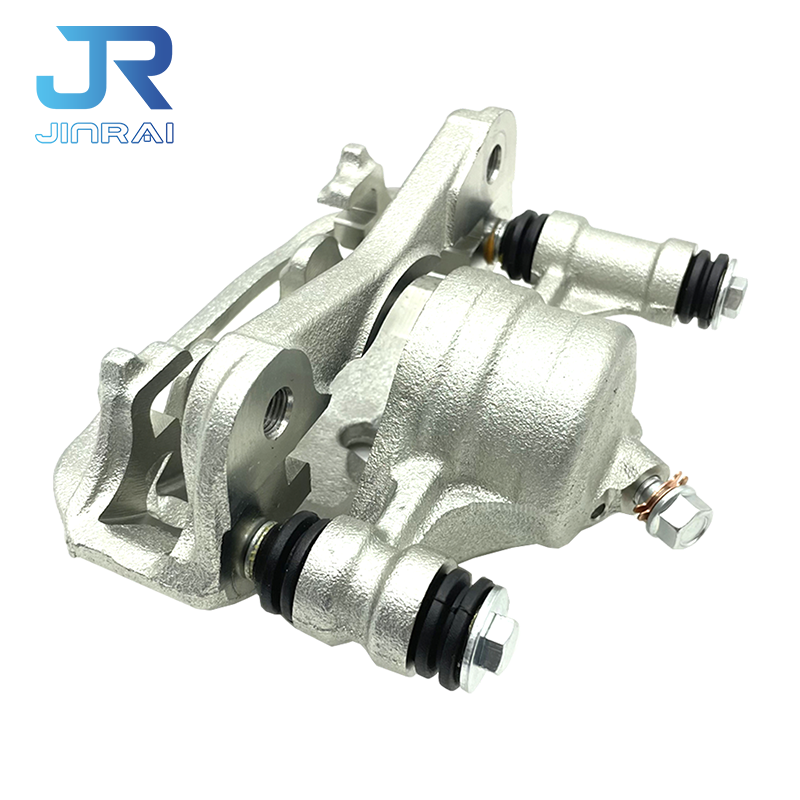

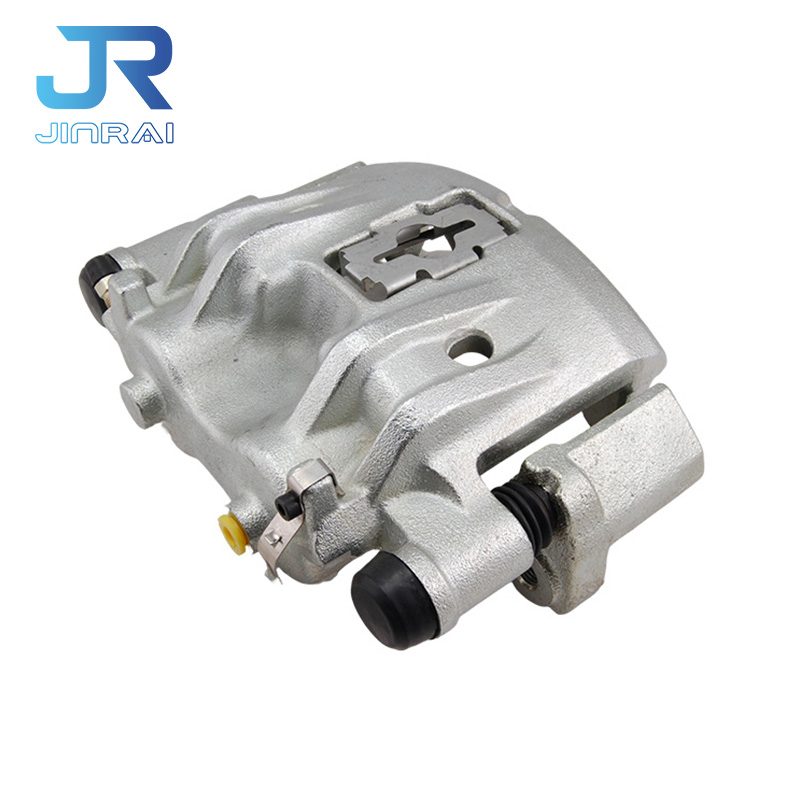

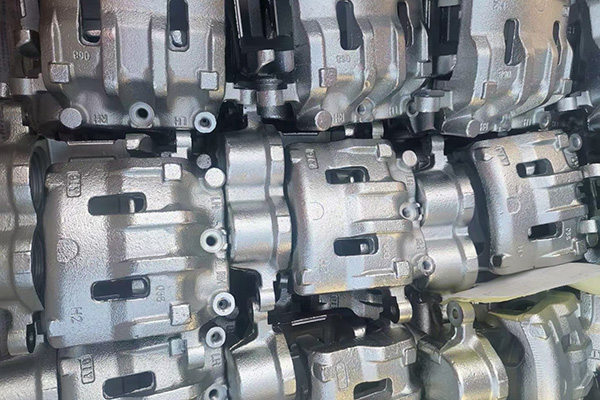

Our Brake Calipers

OE Quality Brake Calipers for the Aftermarket

We focus on what matters most to you and your customers: reliable, high-quality brake calipers that sell well and perform even better.

- High-quality casting with durable anti-rust coating

OE-standard sizing ensures quick installation with zero adjustment

Smooth piston movement for strong, stable braking power

Premium rubber seals for long-lasting reliability

Aluminum or steel piston options based on market needs

Very low defective rate—ideal for building trust with your customers

Our Brake Caliper Materials

Good Materials, Good Brake Caliper

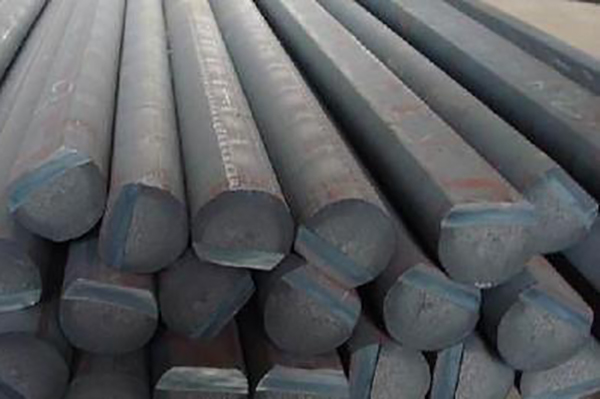

Cast Iron

The most widely used material in the aftermarket.

- High strength and durability

- Excellent heat resistance

- Cost-effective

- Ideal for standard passenger cars and commercial vehicles

Cast Aluminum

Lightweight and commonly used in modern cars and performance vehicles.

- Much lighter than cast iron

- Better heat dissipation

- Corrosion resistant

- Allows more complex shapes

Our Brake Caliper Types

We manufacture high-quality brake calipers according to OE standards, and also support custom brake calipers for you.

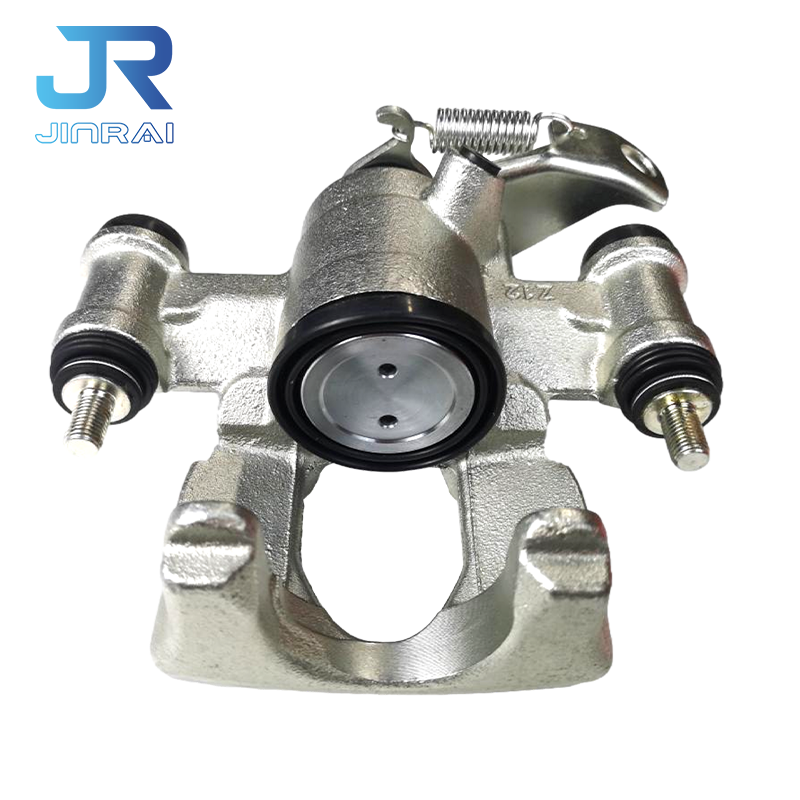

Floating Caliper

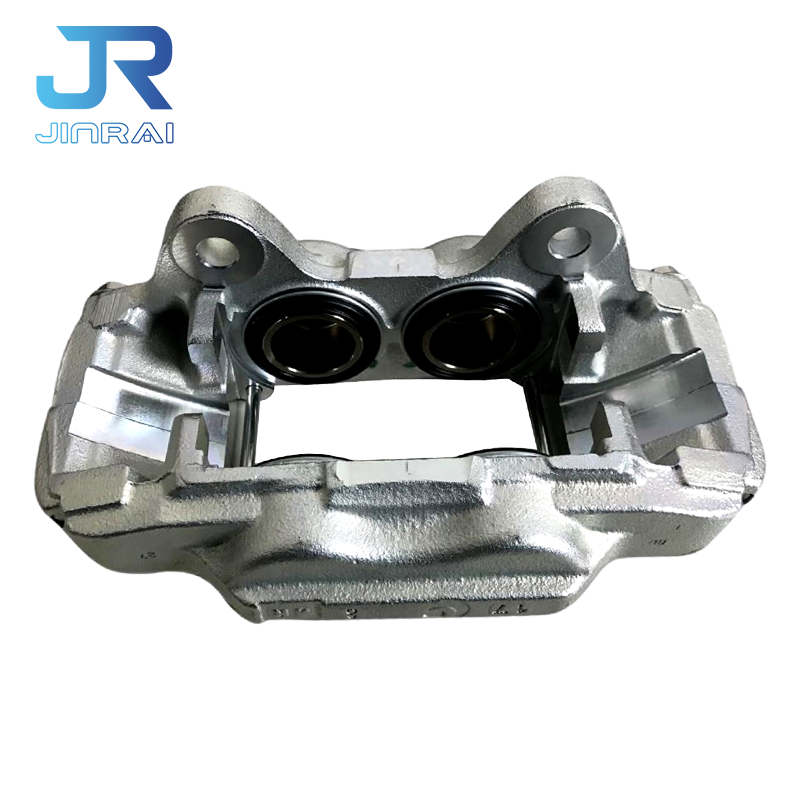

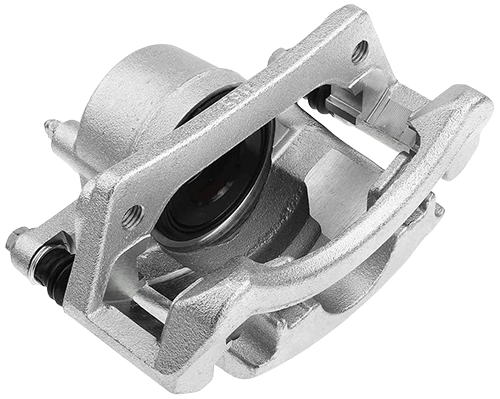

Fixed Caliper

Monoblock Caliper

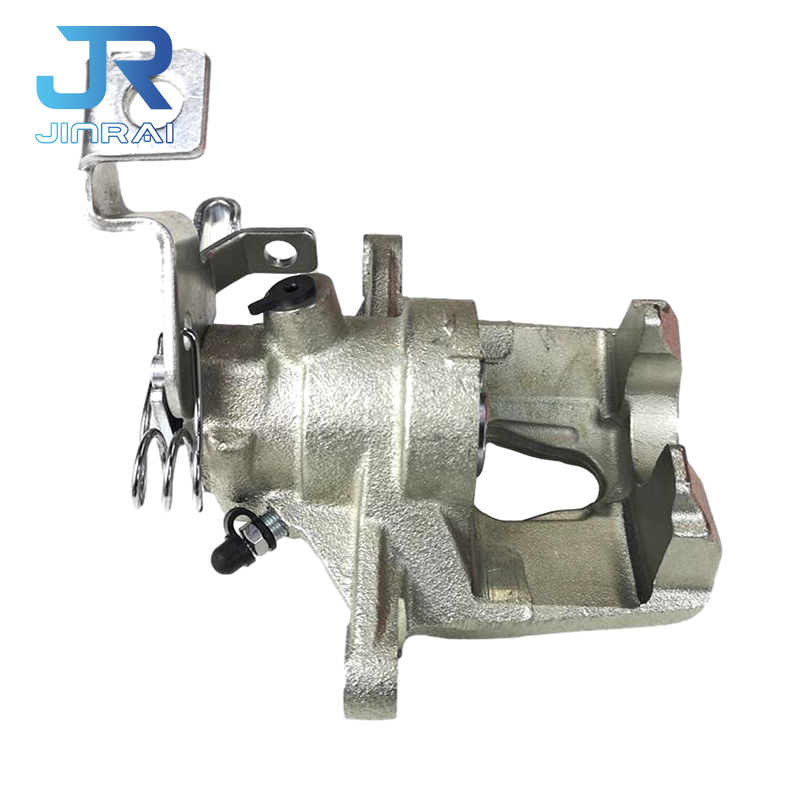

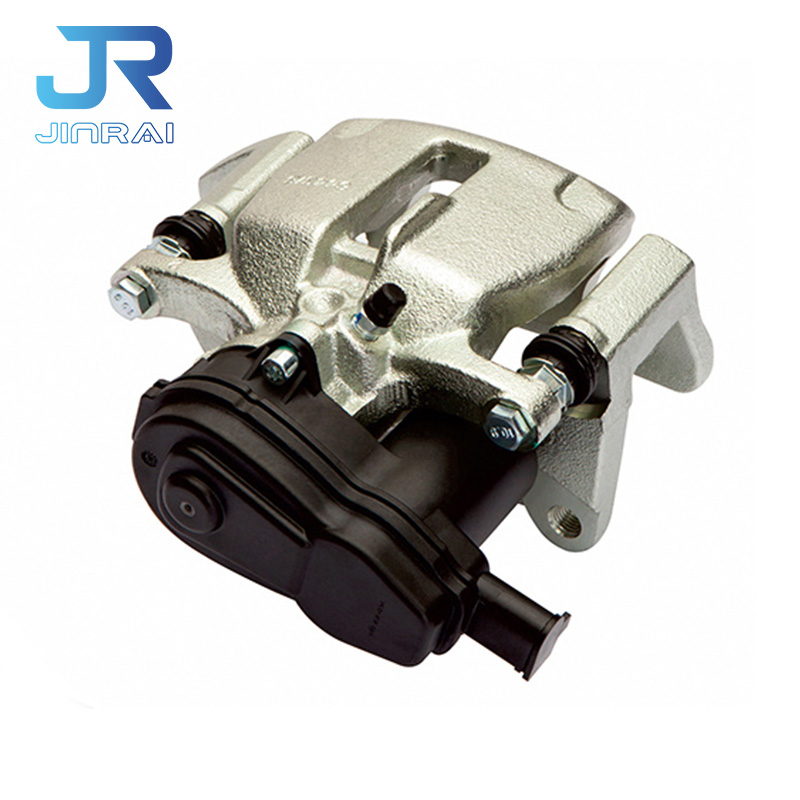

EPB Caliper

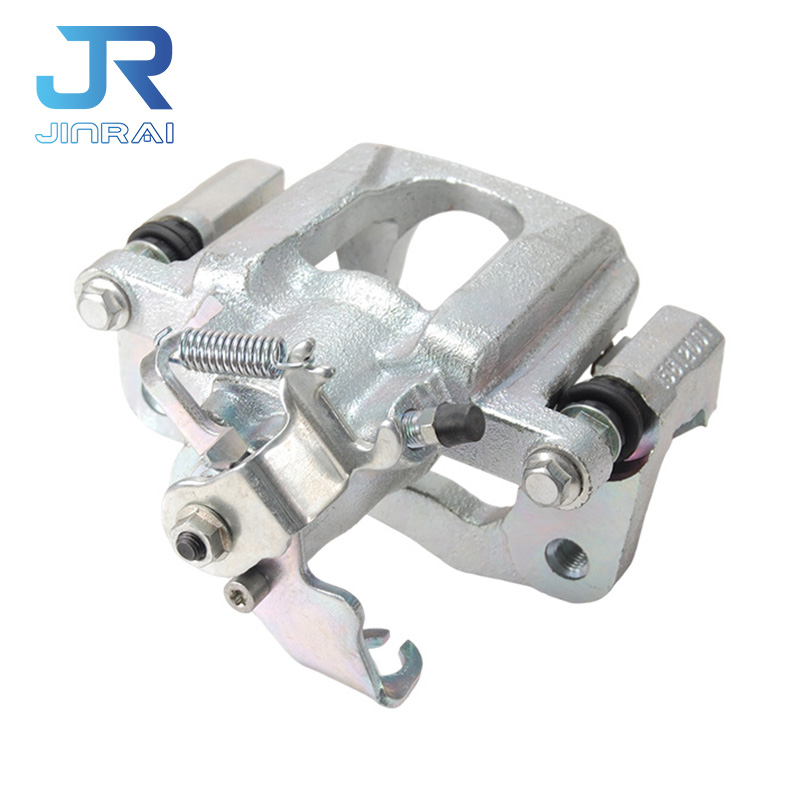

IPB Caliper

| Type | Structural Features | Braking Power | Maintenance Difficulty | Common Vehicle Types |

|---|---|---|---|---|

| Floating Caliper | Single-piston with sliding guide pins | Medium | Easy | Most passenger cars |

| Fixed Caliper | Fixed housing with multiple pistons on both sides | High | Medium | Luxury & performance vehicles |

| Monoblock Caliper | One-piece fixed housing, usually 4–8 pistons | Very High | Medium | Sports cars, performance cars, premium SUVs |

| EPB Caliper | Floating caliper with an integrated electric motor | Medium | Medium | New energy vehicles & modern models |

| IPB Caliper | Mechanical parking mechanism built inside the caliper | Medium | Easy | Certain European models |

Brake Calipers

Brake calipers are one of the most important parts of a disc brake system. For you, knowing the basics about brake calipers can help you choose better products, avoid returns, and support your customers with confidence.

what brake calipers do?

Brake calipers are the key components that allow a vehicle to slow down smoothly and safely.

When you press the brake pedal, hydraulic pressure is sent to the caliper. The caliper then pushes the brake pads directly onto the brake disc. This contact creates the friction needed to reduce the vehicle’s speed.

Every caliper contains pistons, seals, and guide mechanisms that ensure the brake pads move correctly and apply even pressure. If the caliper works well, braking feels stable, the response is quick, and the car stops as expected.

how many calipers on a car?

Most cars have four brake calipers, one on each wheel.

Front wheels: 2 calipers

Rear wheels: 2 calipers

Exceptions:

Cars with rear drum brakes only have 2 calipers on the front wheels.

Some high-performance vehicles may use multi-piston calipers for extra braking power, but still typically have 4 calipers in total.

how long do calipers last?

The lifespan of a brake caliper depends on driving habits, vehicle type, environment, and maintenance. Typically:

Average lifespan: 8–12 years or 100,000–150,000 km (60,000–90,000 miles)

Heavy-duty or high-performance calipers may wear faster under demanding conditions.

Regular inspections and maintenance can extend caliper life and ensure safe braking.

bad brake caliper symptoms

A failing brake caliper can affect braking performance and vehicle safety. Watch for:

- Vehicle pulls to one side during braking

- Spongy or soft brake pedal

- Uneven or accelerated brake pad wear

- Brake fluid leaks around the caliper

- Squealing, grinding, or unusual noises during braking

- Overheating or burning smell near the wheels

how to replace brake calipers?

Replacing a brake caliper requires proper tools and care. General steps:

Lift the vehicle and remove the wheel.

Disconnect the brake hose carefully to avoid fluid loss.

Unbolt and remove the old caliper.

Remove brake pads and any hardware.

Install the new caliper, attach the brake hose, and secure with bolts.

Reinstall brake pads, ensuring proper alignment.

Bleed the brake system to remove air and restore hydraulic pressure.

Test brakes carefully before driving normally.

⚠️ If you are not experienced, have a certified mechanic perform the replacement.

Brake Caliper Factory

Established in 2001, our brake caliper factory is recognized as one of China’s most professional brake caliper manufacturers. With over 20 years of industry experience, we have developed more than 5,000 brake caliper models, covering both passenger cars and commercial vehicles for the global aftermarket.

Our 20,000-square-meter facility employs over 200 skilled workers and is equipped with advanced CNC machines along with complete production and testing equipment. With a stable monthly output of up to 150,000 brake calipers, we ensure consistent quality, efficient production, and reliable delivery.

If you are seeking a dependable brake caliper manufacturing partner with competitive and strong production capacity, we are ready to support your business. Let’s explore long-term cooperation and grow your market together.

How We Produces OE-Quality Brake Calipers?

Strong manufacturing. Reliable performance. Consistent quality.

Raw Material Selection

Brake calipers are usually made from cast iron or aluminum, depending on OE standards. Only qualified materials with verified chemical composition and mechanical properties are accepted to ensure strength, heat resistance, and long-term durability.

Melting & Casting

Molten metal is poured into molds to form the basic caliper body. This method is widely used for standard floating and fixed calipers. After forming, rough castings are cleaned, deburred, and visually inspected.

Heat Treatment

Heat treatment improves the hardness, strength, and structural stability of the caliper body, helping prevent deformation under high braking temperatures and ensuring consistent performance over time.

CNC Machining

- Machining piston bores

Threading mounting holes

Milling sealing grooves

Machining guide pin and bracket interfaces

Surface Treatment & Coating

To improve corrosion resistance and appearance, calipers undergo surface treatment such as:

Zinc plating

Electro-coating (E-coating)

Phosphating or anti-rust coating

Assembly

Each caliper is assembled with:

Pistons

Seals and dust boots

Guide pins and hardware

Assembly is carried out under controlled conditions to prevent contamination and ensure sealing reliability.

Quality Testing

Every batch undergoes strict inspection, including:

Dimensional measurement

Pressure and leakage testing

Piston movement testing

Visual and coating inspection

Final Inspection & Packaging

After final quality checks, brake calipers are cleaned, labeled, and packaged according to customer requirements, including neutral packaging, brand packaging, or customized labeling.

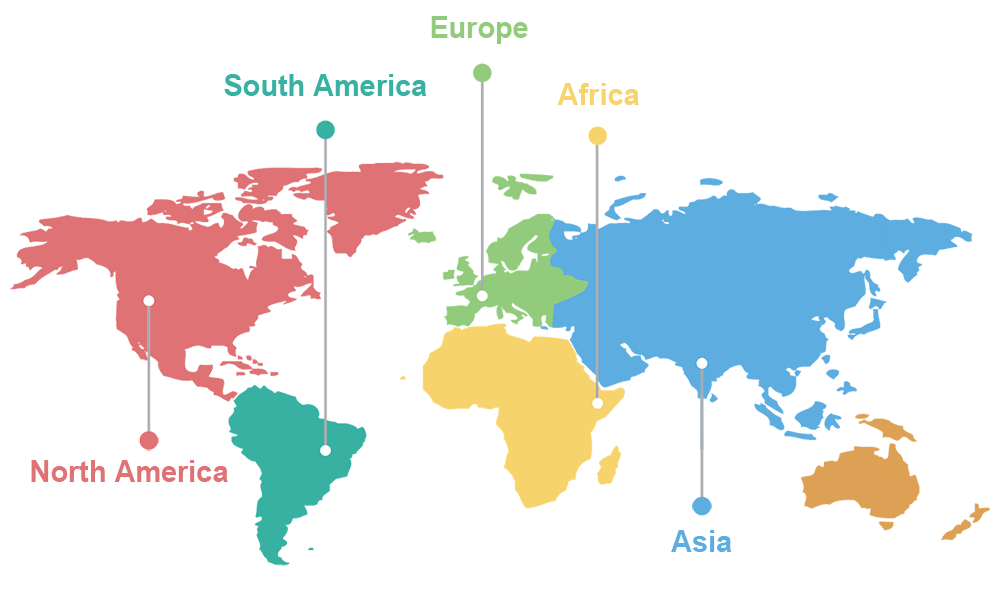

Our Main Markets

North America

America, Canada, Mexico, Guatemala, El Salvador, Honduras, Costa Rica, Panama

South America

Colombia, Venezuela, Suriname, Ecuador, Peru, Bolivia, Brazil, Argentina, Chile

Europe

Finland, Poland, UK, France, Malta, Spain, Portugal, Andorra, Sweden, Belarus, Monaco

Africa

Egypt, Libya, Sudan, Tunisia, Algeria, Morocco, Kenya, Tanzania, Uganda, Gabon, Burkina Faso, Nigeria, Cape Verde, Côte d’Ivoire, Ghana, Zambia, Angola, Zimbabwe, Malawi, South Africa, Madagascar

Asia

South Korea, Japan, Philippines, Vietnam, Laos, Cambodia, Myanmar, Thailand, Malaysia, Indonesia, Bangladesh, India, Pakistan, Sri Lanka, Iraq, Iran, Syria, Jordan, Lebanon, Israel, Palestine, Saudi Arabia, Bahrain, Qatar, Kuwait, United Arab Emirates, Oman, Yemen, Turkey

Why Choose Us?

As a brake caliper factory with rich experience, we provide full support to help you grow your business with ease.

OE Quality

Make production according to OE standards

Competitive Price

Give you factory direct selling prices

Lower MOQ

50pcs each model

OEM&ODM

Support do your customized brand package

Warranty

1 Year after you receive our products

Your challenge VS Our solution

We understand your challenges, so we’ve built solutions for you

Your Challenge with Old Supplier

- Difficult Communication With Suppliers

“When working with some suppliers, communication often feels slow and unclear. I struggle to get precise information about brake caliper specifications, pricing, or production progress, and even simple questions can take days to be answered, which disrupts my business planning.”

- Delivery Delays and Broken Promises

“Some suppliers promise one delivery schedule and then miss it by weeks. That leaves me dealing with unhappy customers, reputational risk, and extra expenses.”

- Receiving Low or Unstable Quality Products

“I’ve received brake calipers with defects such as sticking pistons, seal leaks, uneven movement, or misalignment. I lose many customers and have to handle complaints. So terrible!!!”

- Poor After-Sales Support

“I’ve had suppliers disappear after sending the goods. If something goes wrong, there’s no help or explanation, and I’m left to handle the consequences myself.”

Our Solution

- Good Communication

With customers across 80+ countries, we ensure communication is never a problem. Our experienced team understands brake calipers thoroughly and is here to provide support whenever you need it.

- Fast Delivery on Time

Our factory manufactures approximately 150,000 brake calipers per month, and our typical lead time is 45 days. We offer dependable, on-schedule delivery to keep your business running smoothly.

- Only Produce OE Quality Products

Every brake caliper undergoes strict dimensional inspections, piston movement and sliding tests, leak and pressure tests, and thorough coating and corrosion checks. Only calipers that pass all quality standards are approved for shipment.

- Excellent After-Sales Service

Your satisfaction is our priority. If any problem arises, we provide fair, timely solutions to keep your business running smoothly and assure you of our ongoing support.

More Than A Supplier, Your Trusted Partner

Together with our clients, we build stronger markets through trust, quality, and long-term cooperation.

We join in numerous exhibitions every year, including Automechanika Las Vegas, Mexico, Dubai, Shanghai, and the Canton Fair, to connect with customers face-to-face and understand their real market needs.

We warmly welcome customers to visit our factory. Seeing our production, quality control, and teamwork in person builds trust and long-term confidence.

We are more than just a supplier — we share meals, ideas, and moments with our customers, growing together as partners and friends.

Frequently Asked Questions

Everything you want to know about working with us — answered here.

Are you a manufacturer or a trading company?

What is Your MOQ?

Do you offer customized packaging and branding?

What is your warranty policy?

What payment terms do you accept?

Contact Us

You can send us your inquiry lists, requirements, or suggestions using the following form. We will reach you asap.