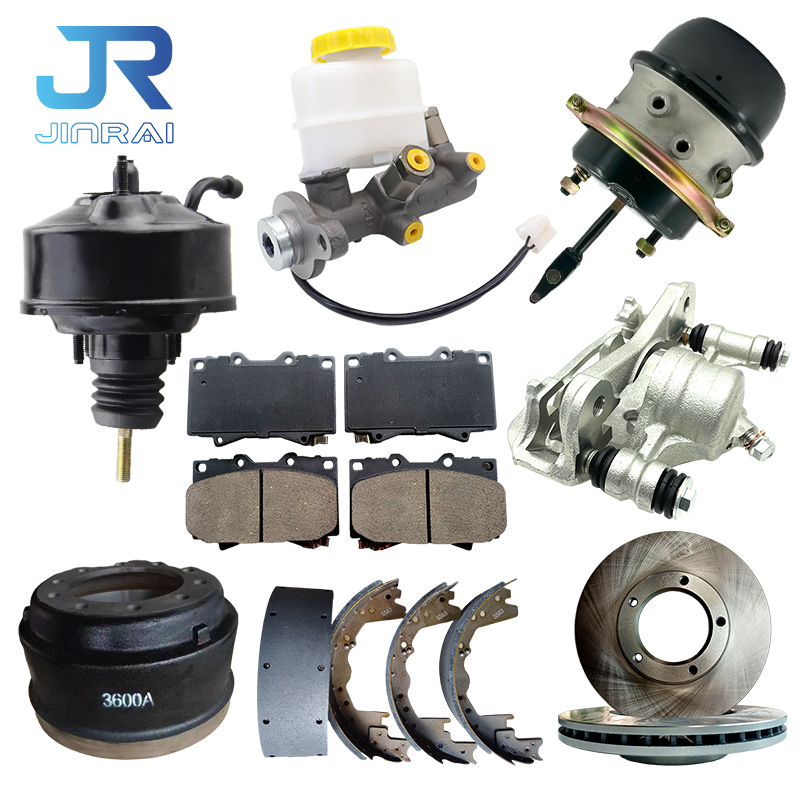

Wholesale Brake Disc Manufacturer

Precise braking, reliable performance – 20 years of experience, exporting to 80+ countries

Brake Disc Manufacturer in China

Anhui Goldenstar Auto Parts is a professional brake disc manufacturer you can truly rely on. For years, we’ve been supplying high-quality brake disc replacements for passenger cars, trucks, and even performance racing vehicles to customers around the world.

Our catalog covers Japanese, Korean, European, and American vehicles. Whether you’re looking for a new supplier you can trust, or planning to expand your current product line, we’re here to help you grow with confidence.

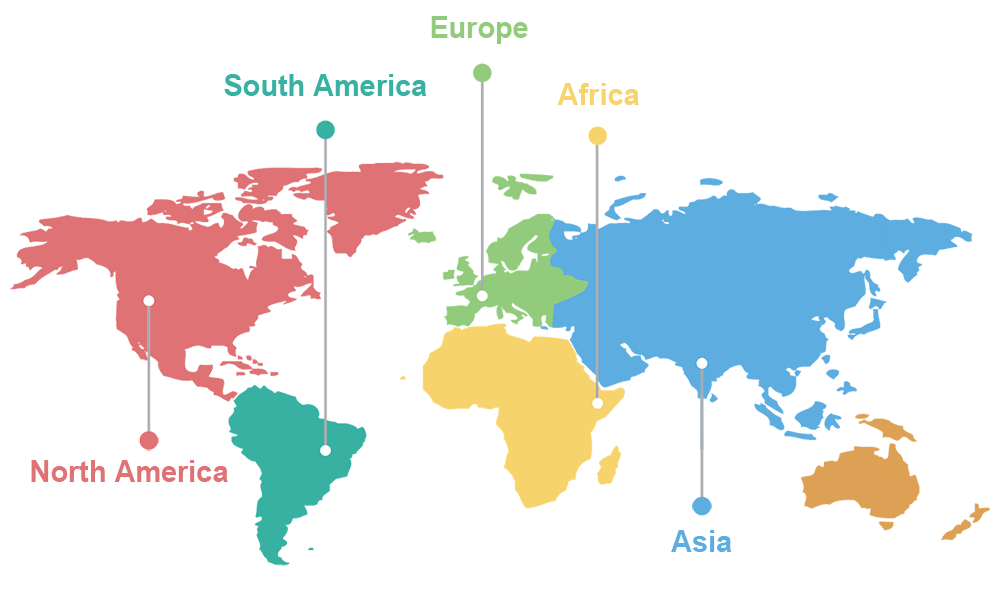

Because of our consistent quality and the way we take care of every customer, our brake discs are now sold in more than 80 countries—including South America, North America, Europe, the Middle East, Africa, and Southeast Asia. Many of our long-term partners started with one order, and now we develop new items together every year.

If you’re searching for a reliable brake disc manufacturer and you’re also thinking about building your own brand, we would be more than happy to support you. From stable quality to flexible customization, we’re ready to help you create products your market will trust.

Let’s build something successful together!

Our Brake Disc Types

All sizes according to OE standards, but we can make types according to your request

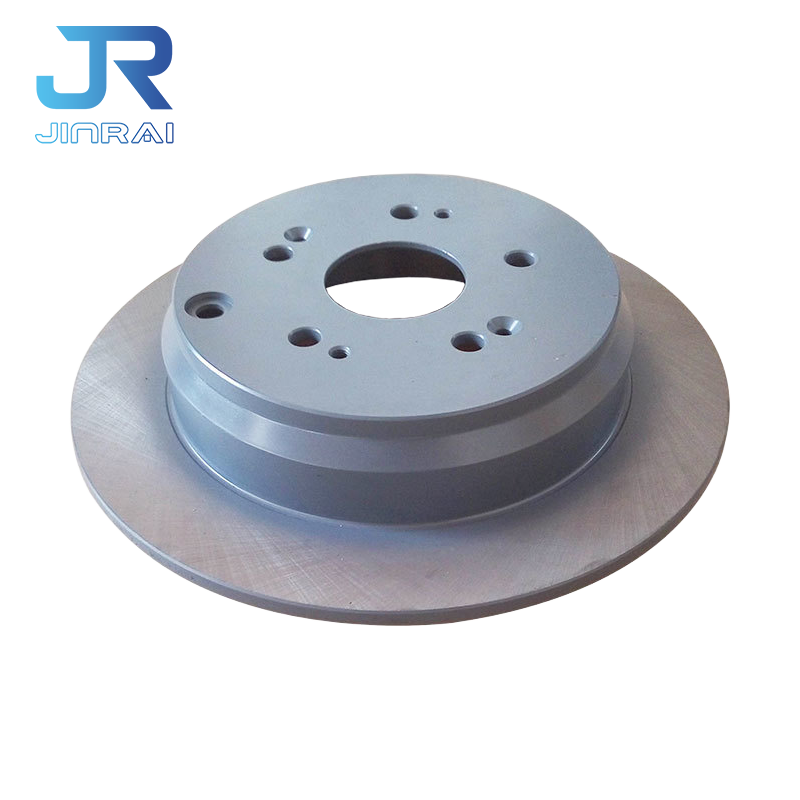

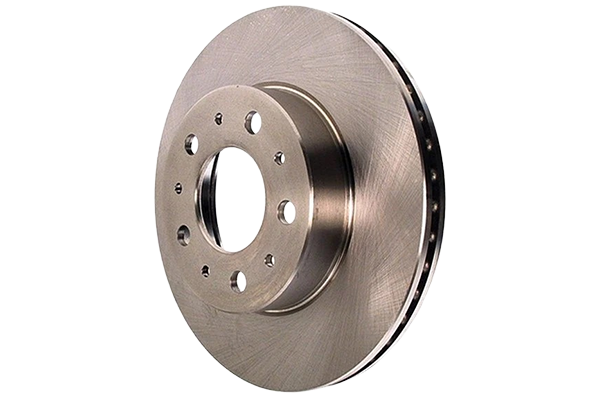

Solid Brake Disc

Structure: One solid piece of cast iron.

Features: Strong, simple, cost-effective; basic heat dissipation.

Best for: Small cars, rear axles, daily driving.

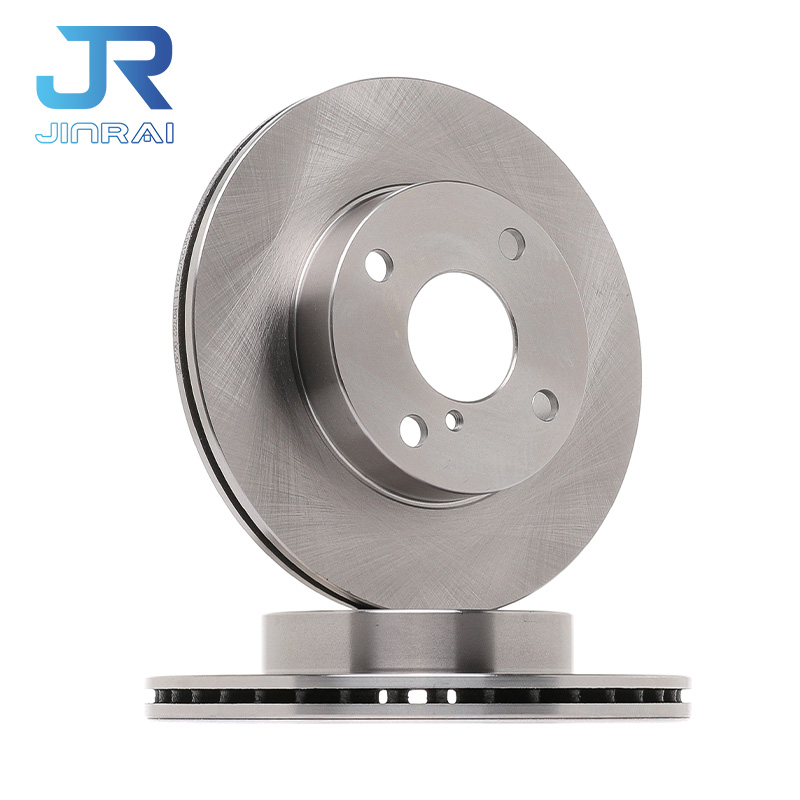

Vented Brake Disc

Structure: Two discs with internal vanes for airflow.

Features: Excellent cooling, reduces brake fade, most common design.

Best for: Front axles, sedans, SUVs, trucks.

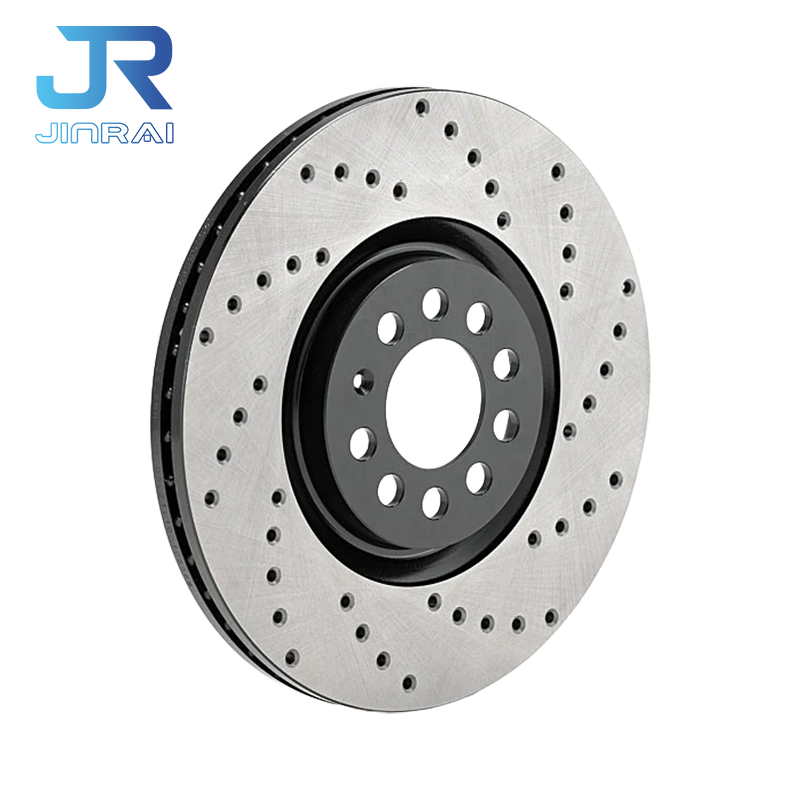

Drilled Brake Disc

Structure: Holes drilled across the disc surface.

Features: Better heat and gas release, improved wet braking, sporty look.

Best for: Performance cars, wet climates, style-focused upgrades.

Slotted Brake Disc

Structure: Grooves machined into the rotor surface.

Features: Cleans pads, stable under repeated braking, high durability.

Best for: SUVs, pickups, heavy vehicles, aggressive driving.

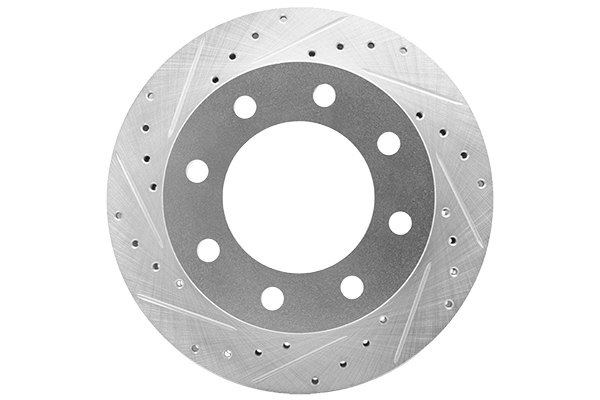

Slotted and Drilled Brake Disc

Structure: Combination of drilled holes and slots.

Features: Maximum cooling and pad cleaning; premium appearance.

Best for: Modified cars, racing use, and high-performance upgrades.

Waved Edge Brake Disc

Structure: Wave-shaped outer edges.

Features: Lighter weight, faster cooling, motorsport look.

Best for: Racing, high-performance vehicles, premium aftermarket.

Our Brake Disc Material

Good Materials, Good Brake Discs

Cast Iron Brake Disc

- Strong and durable

- Cost-effective

- Excellent heat resistance

- Stable braking performance

- Most widely used for passenger cars, SUVs, and trucks

Carbon Ceramic Brake Disc

- Extremely lightweight

- Handles very high temperatures

- Delivers superior braking performance

- Long lifespan and corrosion-free

- Used in supercars, racing, and high-performance vehicles

Our Brake Disc Coating

Advanced coating technology designed for cleaner, stronger, and longer-lasting brake discs.

Geomet Coating

Water-based, environmentally friendly anti-rust coating

Silver or grey appearance

Excellent corrosion resistance, especially in humid or coastal regions

Keeps the hub area clean and prevents rust stains

Very popular in aftermarket premium discs

UV Coating

Applied by spraying and cured with UV light

Smooth, clean finish with strong anti-rust protection

Highly resistant to chemicals and temperature changes

Good for markets that prefer clean, premium-looking discs

Anti-Rust Paint Coating

Typically black or silver high-temperature paint

Basic corrosion protection at an affordable cost

Commonly used for standard aftermarket brake discs

Ideal for cost-sensitive markets

Zinc Phosphate Coating

Chemical treatment that forms a crystal-like protective layer

Improves anti-rust ability and helps paint adhere better

Provides good initial protection before the disc is used

Dacromet Coating

High-temperature, high-strength anti-rust coating

Often used in heavy-duty or commercial vehicle brake discs

Excellent resistance to salt spray and harsh environments

Black E-Coating

Even and durable black coating

Strong corrosion resistance

Very stable and long-lasting compared to normal paint

Popular in North America and Europe

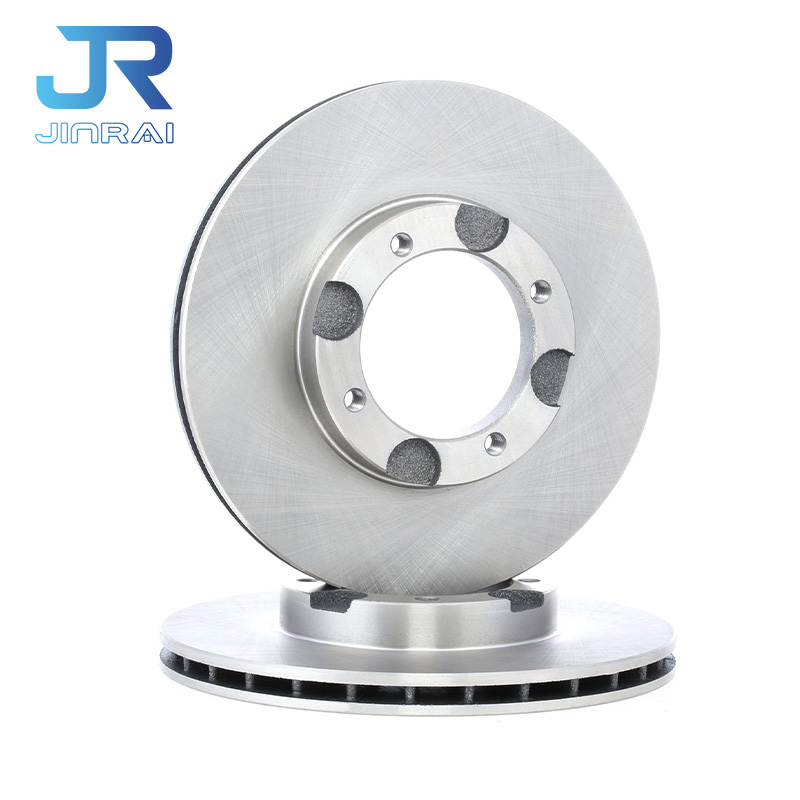

Our Brake Discs

The brake disc, also called a brake rotor, is a vital part of a vehicle’s braking system, working with brake pads to provide consistent stopping power, enhance vehicle control, and ensure driver and passenger safety. High-quality brake discs reduce wear, prevent deformation, and deliver stable performance even under extreme conditions.

Strong heat dissipation to prevent brake fade

Precision machining for perfect fitment and smooth braking

Warp-resistant for long service life

Low noise & low vibration for a comfortable driving experience

Uniform hardness for even wear and consistent performance

Anti-rust coating for long-lasting protection

Stable braking feel in both high and low temperatures

NA01-33-25X

Front Axle

Height: 45 mm

Diameter: 235 mm

Centering Diameter: 55 mm

Pitch Circle Diameter: 100 mm

Brake Disc Thickness: 18.0 mm

Minimum Thickness: 16 mm

Num. of holes: 4

Solid or Vented: V

Weight: 3.7 kg

34216764655

Rear Axle

Height: 67.3 mm

Diameter: 336 mm

Centering Diameter: 75 mm

Pitch Circle Diameter: 120 mm

Brake Disc Thickness: 22.0 mm

Minimum Thickness: 20.4 mm

Num. of holes: 5

Solid or Vented: V

Weight: 8.2 kg

42431-33050

Rear Axle

Height: 64 mm

Diameter: 288 mm

Centering Diameter: 62 mm

Pitch Circle Diameter: 114 mm

Brake Disc Thickness: 10 mm

Minimum Thickness: 8.5 mm

Num. of holes: 5

Solid or Vented: S

Weight: 5 kg

1907725

Front Axle

Height: 129 mm

Diameter: 304 mm

Centering Diameter: 165 mm

Pitch Circle Diameter: 205 mm

Brake Disc Thickness: 30 mm

Minimum Thickness: 27.8 mm

Num. of holes: 6

Solid or Vented: V

Weight: 13.8 kg

DD32-33-25X

Front Axle

Height: 43.4 mm

Diameter: 258 mm

Centering Diameter: 63.5 mm

Pitch Circle Diameter: 108 mm

Brake Disc Thickness: 22.0 mm

Minimum Thickness: 20 mm

Num. of holes: 4

Solid or Vented: V

Weight: 5.1 kg

42510-SR3-G00

Rear Axle

Height: 47.6 mm

Diameter: 239 mm

Centering Diameter: 61 mm

Pitch Circle Diameter: 100 mm

Brake Disc Thickness: 9.0 mm

Minimum Thickness: 8 mm

Num. of holes: 4

Solid or Vented: S

Weight: 2.9 kg

51712-24100

Front Axle

Height: 41 mm

Diameter: 242 mm

Centering Diameter: 86 mm

Pitch Circle Diameter: 104 mm

Brake Disc Thickness: 19 mm

Minimum Thickness: 17.7 mm

Num. of holes: 4

Solid or Vented: V

Weight: 4.25 kg

1244211512

Front Axle

Height: 49.5 mm

Diameter: 295 mm

Centering Diameter: 67 mm

Pitch Circle Diameter: 112 mm

Brake Disc Thickness: 22.0 mm

Minimum Thickness: 19.4 mm

Num. of holes: 5

Solid or Vented: V

Weight: 6.6 kg

Brake Disc Factory

Our brake disc factory was established in 1958, and for decades, we’ve focused on producing reliable, high-quality replacement brake discs for the global aftermarket.

Today, our facility spans 100,000 ㎡ and is equipped with everything necessary for professional, large-scale production, including fully automatic casting lines, automated coating lines, CNC machining centers, and comprehensive laboratory and physical testing equipment. Every disc goes through strict production and inspection processes before it reaches your hands.

If you’re looking for a brake disc manufacturer you can count on for quality, capacity, and honest cooperation, we would be excited to work with you and support the growth of your business.

How We Produces OE-Quality Brake Discs?

Strong manufacturing. Reliable performance. Consistent quality.

Raw Material Selection

We start with strict material control. All our brake discs use premium gray cast iron. Every batch of molten iron is tested in our laboratory to ensure the right balance of carbon, silicon, manganese, and other elements. Stable material composition is the foundation of heat resistance, durability, and braking performance.

Melting & Casting

Once the molten iron reaches the required temperature, it enters our fully automatic casting line. The automated pouring system ensures each blank has consistent dimensions and uniform structure. This stage forms the “skeleton” of the brake disc—if the casting is solid, the product will be reliable.

Cooling & Cleaning

After casting, the brake disc blank is left to cool naturally. Proper cooling ensures the internal structure is stable. Once cooled, the blank goes through shot-blasting and cleaning to remove burrs, sand, and any surface defects—preparing it for precision machining.

Precision CNC Machining

Machining is one of the most important steps. With multiple automated machining lines, every disc goes through turning, drilling, chamfering, and dynamic balancing.

- Double-side machining ensures perfectly flat surfaces

- Dynamic balance testing prevents vibration during braking

- Precision measurement keeps all dimensions within tolerance

Anti-Rust Treatment & Coating

After machining, the discs go to our automatic coating line. We apply an environmentally friendly anti-rust coating to protect the product during storage and transport. This also gives the brake disc a clean, professional appearance.

Final Inspection & Packaging

Before shipment, our QC team performs a full inspection of each disc:

- Thickness

- Runout and flatness

- Weight

- Balance value

- Surface condition

Only discs that pass all tests are packed and shipped to customers.

Our Main Markets

North America

America, Canada, Mexico, Guatemala, El Salvador, Honduras, Costa Rica, Panama

South America

Colombia, Venezuela, Suriname, Ecuador, Peru, Bolivia, Brazil, Argentina, Chile

Europe

Finland, Poland, UK, France, Malta, Spain, Portugal, Andorra, Sweden, Belarus, Monaco

Africa

Egypt, Libya, Sudan, Tunisia, Algeria, Morocco, Kenya, Tanzania, Uganda, Gabon, Burkina Faso, Nigeria, Cape Verde, Côte d’Ivoire, Ghana, Zambia, Angola, Zimbabwe, Malawi, South Africa, Madagascar

Asia

South Korea, Japan, Philippines, Vietnam, Laos, Cambodia, Myanmar, Thailand, Malaysia, Indonesia, Bangladesh, India, Pakistan, Sri Lanka, Iraq, Iran, Syria, Jordan, Lebanon, Israel, Palestine, Saudi Arabia, Bahrain, Qatar, Kuwait, United Arab Emirates, Oman, Yemen, Turkey

Why Choose Us?

As a brake disc factory with rich experience, we provide full support to help you grow your business with ease.

OE Quality

Make production according to OE standards

Competitive Price

Give you factory direct selling prices

Lower MOQ

50pcs each model

OEM&ODM

Support do your customized brand package

Warranty

1 Year after you receive our products

Your challenge VS Our solution

We understand your challenges, so we’ve built solutions for you

Your Challenge

- Difficult Communication With Suppliers

“When I work with some suppliers, communication is slow and confusing. I can’t get clear answers about brake disc specifications, prices, or production updates. Sometimes I wait days for a simple reply, and it affects my business schedule.”

- Delivery Delays and Broken Promises

“I’ve had suppliers promise one lead time but deliver weeks late. This puts me under pressure with my own customers, damages my reputation, and creates unnecessary costs.”

- Receiving Low or Unstable Quality Products

“I have received brake discs with runout issues, uneven thickness, rust problems, or noisy performance. When quality is unstable, I lose customers and have to handle complaints.”

- Poor After-Sales Support

“Some suppliers disappear after shipping the goods. When an issue happens, I can’t get help, solutions, or even explanations. I’m left alone to handle all the losses.”

Our Solution

- Good Communication

With customers in more than 80 countries, communication has never been an issue for us. Our team understands brake discs well and knows how to support you clearly and professionally. Whenever you need help, we’re here.

- Fast Delivery on Time

We produce about 400,000 brake discs per month, and our standard lead time is 45 days. With this strong production capacity, you can rely on us for stable, on-time delivery with no unexpected delays.

- Only Produce OE Quality Products

Every brake disc goes through strict dimensional measurements, dynamic balance testing, and thorough coating inspections. Only the discs that meet all quality standards, are approved for packing.

- Excellent After-Sales Service

We take after-sales support seriously. If any issue occurs, we will work closely with you to find a fair solution. We aim to keep your business running smoothly and give you confidence that we’re always here to support you.

More Than A Supplier, Your Trusted Partner

Together with our clients, we build stronger markets through trust, quality, and long-term cooperation.

We join in numerous exhibitions every year, including Automechanika Las Vegas, Mexico, Dubai, Shanghai, and the Canton Fair, to connect with customers face-to-face and understand their real market needs.

We warmly welcome customers to visit our factory. Seeing our production, quality control, and teamwork in person builds trust and long-term confidence.

We are more than just a supplier — we share meals, ideas, and moments with our customers, growing together as partners and friends.

Frequently Asked Questions

Everything you want to know about working with us — answered here.

Are you a manufacturer or a trading company?

What is Your MOQ?

Do you offer customized packaging and branding?

What is your warranty policy?

What payment terms do you accept?

Contact Us

You can send us your inquiry lists, requirements, or suggestions using the following form. We will reach you asap.