Wholesale Brake Drum Manufacturer

Buy from us to save your costs and get more profits, with 1-year warranty

Brake Drum Manufacturer in China

We are a professional brake drum manufacturer specializing in high-quality replacement brake drums for heavy trucks and trailers in the global aftermarket. Our brake drums cover a full selection of models for Benz, MAN, Scania, Volvo, DAF, SAF, Hino, Mitsubishi, Daewoo, Hyundai, BPW, Iveco, ROR, Fruehauf, Renault, Nissan, Isuzu, and Mazda commercial vehicles.

Today, our brake drums are exported to North America, Europe, the Middle East, Africa, and other regions, earning strong recognition in global markets. Many long-term partners continue to choose us because our products help reduce complaints, improve customer satisfaction, and keep their business running smoothly.

If you are looking for a dependable brake drum supplier to strengthen your product line and grow your business, contact us today. Send us your OE numbers list, and we’ll provide fast quotes, stable quality, and long-term support.

Our Brake Drums Application

Cover all models you need

Heavy-Duty Trucks

Mercedes-Benz Actros / Axor

MAN TGX / TGS

Volvo FM / FH

Scania R-Series / P-Series

DAF XF / CF

HINO 500 / 700

Mitsubishi Fuso

Trailers / Semi-Trailers

SAF axles

BPW axles

FUWA axles

York axles

Light Commercial Vehicles

Isuzu N-Series

JAC N-Series

Foton Aumark / Forland

Older Passenger Cars

Toyota Corolla

Honda Fit

Nissan Sunny

Volkswagen Jetta

Hyundai Accent / Kia Rio

Our Brake Drums

Brake drum is an important part of the brake system; choosing a reliable brake drum means fewer complaints, stronger customer trust, and long-term business growth. That’s why a high-quality brake drum is not just important—it’s a key advantage in the aftermarket.

- Stable braking power under high load

- Excellent heat dissipation for longer service life

- High-strength cast iron to resist wear and deformation

- Precision machining for low vibration and smooth operation

- Anti-rust surface treatment for better protection

43206-08G11

Rear Axle

Height: 73 mm

Inner Brake Drum Height: 63.5 mm

Diameter: 300 mm

Drum Diameter: 260 mm

Center Diameter: 100.5 mm

Pitch Circle Diameter: 139.7 mm

Num. of holes: 6

81501100232

Front Axle

Drum diameter: 410mm

Bolt Hole Circle Ø: 335mm

Weight: 42,7kg

Height: 232mm

Hub Bore Diameter: 298mm

Bore Diameter: 23mm

Number of holes: 10

Brake Surface: 187mm

3464230501

Rear Axle

Height: 280mm

Inner brake drum height: 192mm

Drum Diameter: 410mm

Hub Bore Diameter: 298mm

Bore Diameter: 23mm

Weight: 192

Number of Holes: 10

Brake Surface: 192mm

601 423 51 01

Rear Axle

Height: 72 mm

Inner Brake Drum Height: 43 mm

Diameter: 266 mm

Drum Diameter: 230 mm

Center Diameter: 85 mm

Pitch Circle Diameter: 130 mm

Num. of holes: 5

3600A

Rear Axle

Height: 269 mm

Bolt Hole Circle Ø: 286mm

Bolt Hole: 25.4mm

Number of Holes: 10

Brake Size: 420*178mm

8-98030-385-0

Rear Axle

Height: 80.4 mm

Inner Brake Drum Height: 60.5 mm

Diameter: 339.5 mm

Drum Diameter: 295 mm

Center Diameter: 101 mm

Pitch Circle Diameter: 139.7 mm

Number of Holes: 6

7 296 356

Rear Axle

Height: 76 mm

Inner Brake Drum Height: 41.5 mm

Diameter: 216 mm

Drum Diameter: 180 mm

Center Diameter 1: 63.2 mm

Center Diameter 2: 50.2 mm

Pitch Circle Diameter: 108 mm

Num. of holes: 4

MK321338

Front Axle

Height: 155.2 mm

Inner Brake Drum Height: 120 mm

Diameter: 374 mm

Drum Diameter: 320 mm

Center Diameter: 175 mm

Pitch Circle Diameter: 222 mm

Number of Holes: 6

Brake Drum Factory

Founded in 1958, our brake drum factory boasts full in-house capabilities—from raw casting and precision machining to surface treatment and rigorous testing—we ensure that every product meets the highest standards.

Equipped with over 50 advanced machining lines, we produce 300,000pcs per month, delivering consistent quality with reliable lead times you can count on. To date, we have developed over 1,000 brake drum models. For models not within our range, we offer custom solutions based on your samples.

Looking forward to working with us soon!

How We Produces OE-Quality Brake Drums?

Strong manufacturing. Reliable performance. Consistent quality.

Premium Raw Materials

Only high-quality cast iron is selected to ensure strength, heat resistance, and long-lasting durability. Every batch is tested for consistency before production.

Advanced Casting Process

Our controlled melting and precision casting techniques produce brake drums with uniform density and minimal defects, forming a strong foundation for superior performance.

Heat Treatment

Each drum undergoes heat treatment to relieve internal stresses and enhance hardness, ensuring it withstands heavy loads and high temperatures without warping.

Precision CNC Machining

Critical dimensions, including inner diameter, thickness, and bolt holes, are machined with CNC accuracy to match OE specifications perfectly.

Dynamic Balancing

Every drum is balanced to minimize vibrations and ensure smooth, safe braking under all driving conditions.

Surface Treatment

- Shot Blasting: Strengthens the surface and removes impurities.

- Anti-Rust Coating: Keeps the drum protected during storage and transport, ensuring it arrives in perfect condition.

Strict Quality Control

We inspect every drum for dimensions, hardness, and run-out. Only products that meet our stringent OE-level standards are approved for shipment.

Packaging and Shipping

Finally, the brake drums are carefully packaged to prevent damage during transit and delivered with reliable lead times for global customers.

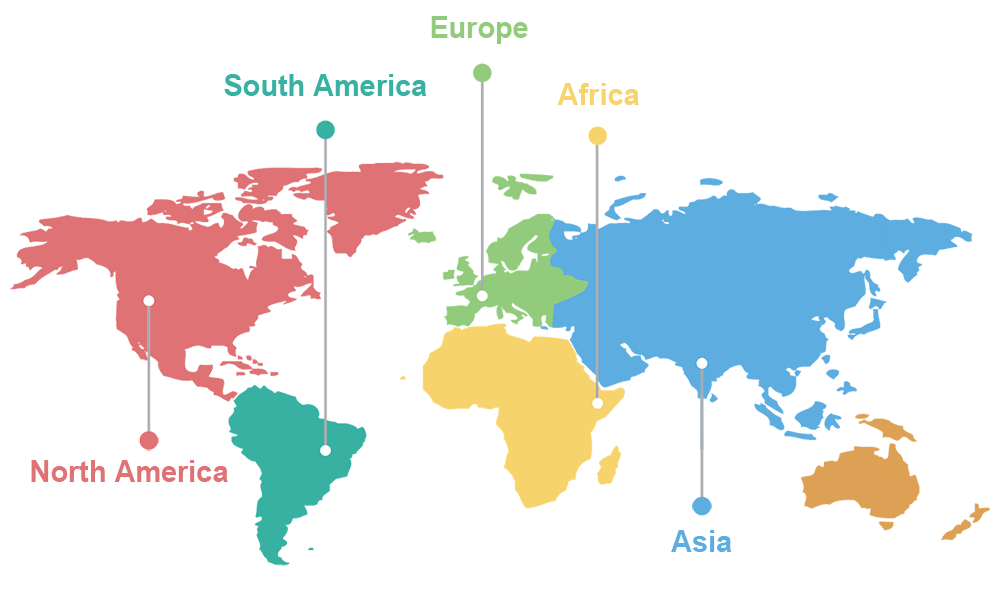

Our Main Markets

North America

America, Canada, Mexico, Guatemala, El Salvador, Honduras, Costa Rica, Panama

South America

Colombia, Venezuela, Suriname, Ecuador, Peru, Bolivia, Brazil, Argentina, Chile

Europe

Finland, Poland, UK, France, Malta, Spain, Portugal, Andorra, Sweden, Belarus, Monaco

Africa

Egypt, Libya, Sudan, Tunisia, Algeria, Morocco, Kenya, Tanzania, Uganda, Gabon, Burkina Faso, Nigeria, Cape Verde, Côte d’Ivoire, Ghana, Zambia, Angola, Zimbabwe, Malawi, South Africa, Madagascar

Asia

South Korea, Japan, Philippines, Vietnam, Laos, Cambodia, Myanmar, Thailand, Malaysia, Indonesia, Bangladesh, India, Pakistan, Sri Lanka, Iraq, Iran, Syria, Jordan, Lebanon, Israel, Palestine, Saudi Arabia, Bahrain, Qatar, Kuwait, United Arab Emirates, Oman, Yemen, Turkey

Why Choose Us?

As a brake drum factory with rich experience, we provide full support to help you grow your business with ease.

OE Quality

Make production according to OE standards

Competitive Price

Give you factory direct selling prices

Lower MOQ

50pcs each model

OEM&ODM

Support do your customized brand package

Warranty

1 Year after you receive our products

Your challenge VS Our solution

We understand your challenges, so we’ve built solutions for you

Your Challenge with other supplier

- Difficult Communication

“Sometimes I get slow responses from suppliers, and their answers don’t address what I really need. It feels like they don’t fully understand my requirements, which makes communication really frustrating.”

- Delivery Delays and Broken Promises

“My previous supplier kept delaying every delivery. Even when they promised a date, they would push it further, and I just couldn’t tolerate it. My clients even started complaining to me because of the delays.”

- Receiving Low or Unstable Quality Products

“Sometimes when I receive goods, they arrive damaged or with missing quantities. What’s even worse is when my customers buy the products and later discover quality issues, leading to returns. These problems have seriously affected my business.”

- Poor After-Sales Support

“Every time I run into after-sales issues and turn to my supplier for support, they always try to avoid the problem, leaving me to handle my customers’ complaints on my own.”

Our Solution

- Good Communication

We work with customers in more than 80 countries, so communication is never a problem. Our team knows brake drums well and can give you clear, helpful support whenever you need it.

- Fast Delivery on Time

We manufacture around 300,000 brake drums every month, and our usual lead time is 45 days. With this production capacity, you can count on us to deliver your orders on time without surprises.

- Only Produce OE Quality Products

Each brake drum is checked carefully — from size measurements to balance testing and coating inspection. Only the brake drums that pass all these checks are allowed to be packed and shipped.

- Excellent After-Sales Service

We take after-sales support seriously. If there’s ever a problem, we’ll work with you to solve it in a fair and timely way. Our goal is to keep your business running smoothly and make you feel confident that we’re always here to help.

More Than A Supplier, Your Trusted Partner

Together with our clients, we build stronger markets through trust, quality, and long-term cooperation.

We take part in several exhibitions every year, such as Automechanika Las Vegas, Mexico, Dubai, Shanghai, and the Canton Fair. These events give us the chance to meet customers face-to-face, understand each other better, and discuss future plans.

We warmly welcome customers to visit our factory. You can see firsthand how we produce high-quality brake drums, and we hope the visit will give you even more confidence in our products.

To us, you’re more than just a customer, and we’re more than just a supplier. We see each other as trusted partners and friends. It’s a joy to share meals and happy moments together.

Frequently Asked Questions

Everything you want to know about working with us — answered here.

Are you a manufacturer or a trading company?

What is Your MOQ?

Do you offer customized packaging and branding?

What is your warranty policy?

What payment terms do you accept?

Contact Us

You can send us your inquiry lists, requirements, or suggestions using the following form. We will reach you asap.