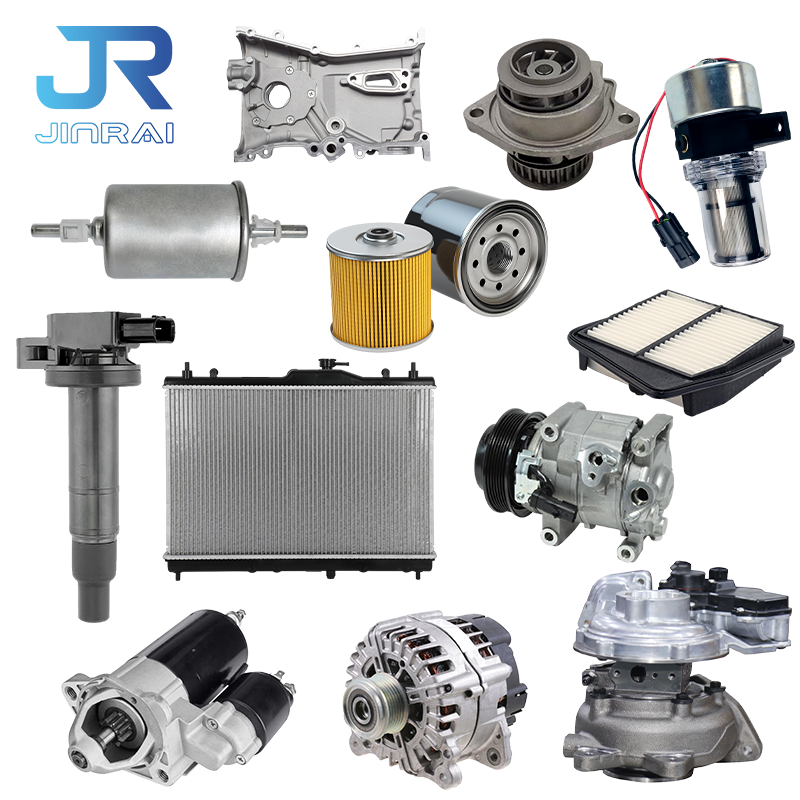

Wholesale Brake Shoe Manufacturer

We help aftermarket brake brands grow with reliable, brand-ready brake shoes from China.

Brake Shoe Manufacturer in China

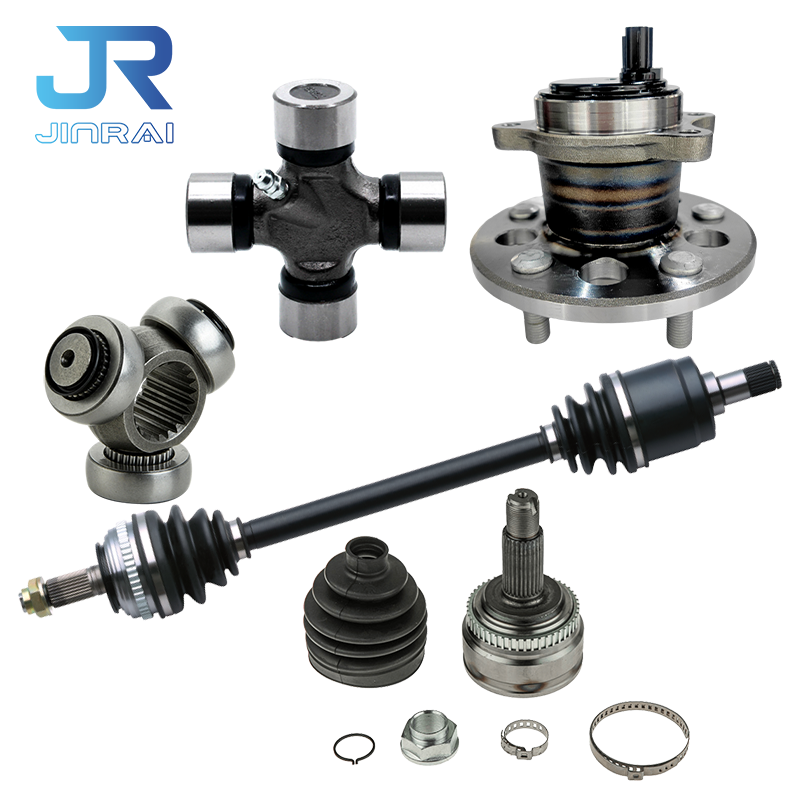

Anhui Goldenstar Auto Parts is a professional brake shoe manufacturer in China, specializing in the development and production of high-quality brake shoes for the global aftermarket.

With years of manufacturing experience, the company focuses on supplying trailer brake shoes, truck brake shoes, and car brake shoes, covering a wide range of Japanese, Korean, European, and American vehicle applications.

So far, more than 1,000 brake shoe models have been developed, meeting the demand of the most popular vehicles in the aftermarket.

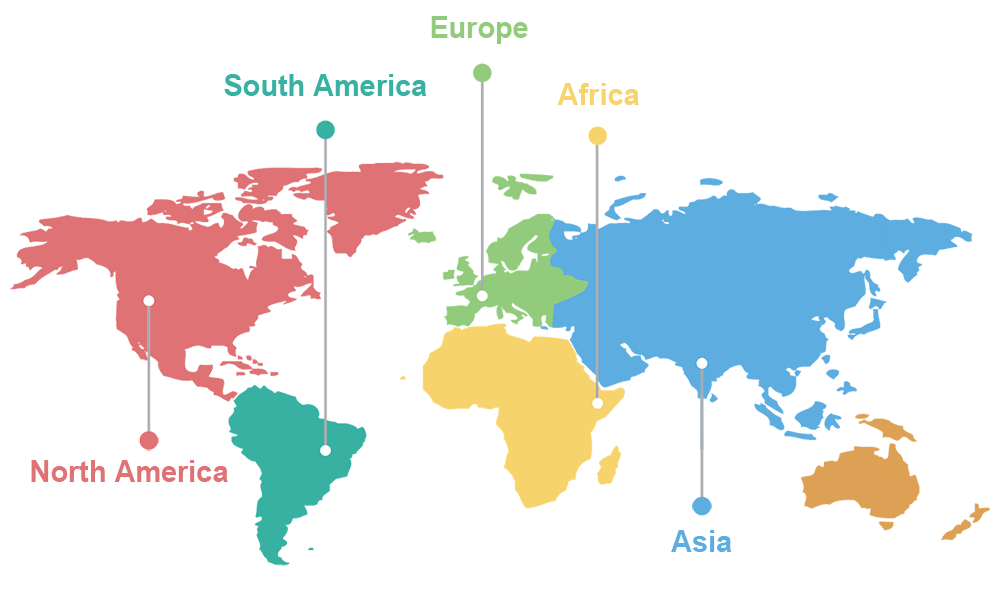

Our brake shoes are exported to North America, South America, Europe, the Middle East, Southeast Asia, Africa, and over 80 countries worldwide, helping customers source reliable brake shoes with stable quality and competitive pricing.

If you are searching for a stable China brake shoe factory with real production strength, feel free to contact us for pricing and cooperation.

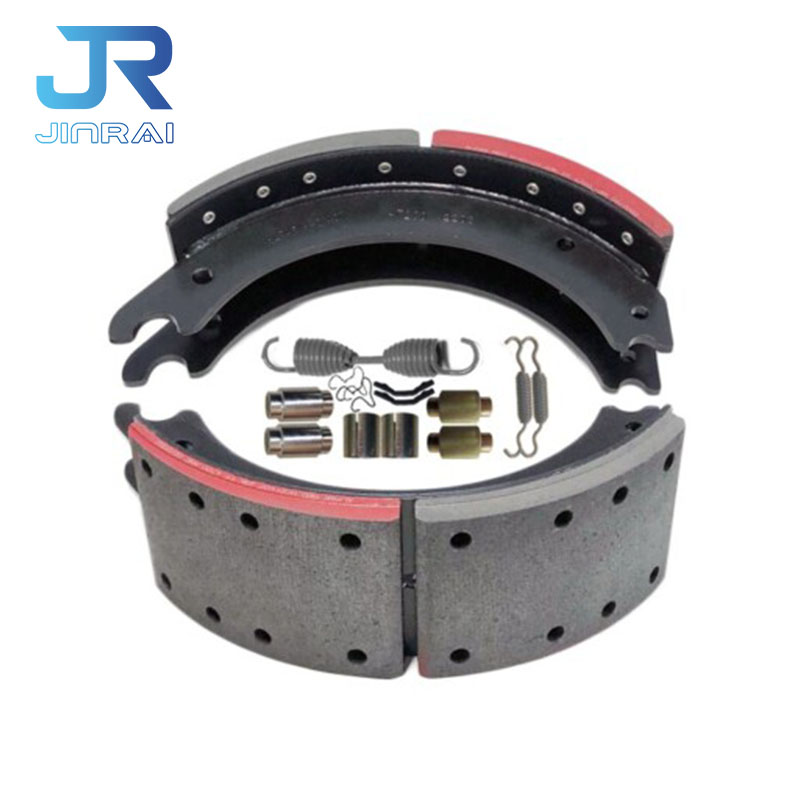

Our Brake Shoes

High-Quality Brake Shoes for the Aftermarket

Our brake shoes are engineered for consistent braking performance, long service life, and stable quality, making them a reliable choice for global aftermarket distributors.

Premium friction materials for stable braking and low fade

High-strength steel shoe webs to prevent deformation

Secure bonding or heavy-duty riveting for longer service life

Low noise and low dust performance

OEM-accurate dimensions for precise fitment

Consistent quality suitable for bulk and repeat orders

Brake Shoe Types

All sizes according to OE standards, 100% perfect fit and high performance

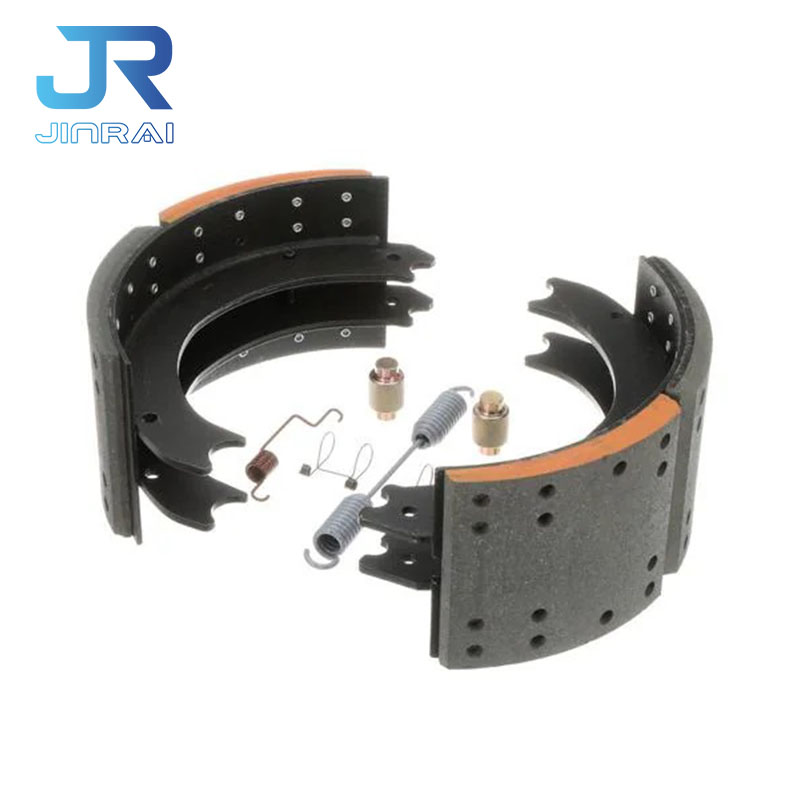

Trailer Brake Shoes

Designed for heavy loads and frequent braking, suitable for trailers and semi-trailers used in logistics and transportation.

Truck Brake Shoes

Built for medium- and heavy-duty trucks, offering reliable braking performance and wear resistance for demanding road conditions.

Car Brake Shoes

Covering a wide range of rear drum brake systems for popular passenger vehicles in aftermarket replacement.

Brake Shoe Friction Material

Good Materials, Good Brake Shoes

semi-metallic brake shoe

With a higher metal content, semi-metallic brake shoes provide stronger braking force and improved heat dissipation. They are commonly used in light trucks and commercial vehicles where higher load capacity and longer service life are required.

Ceramic Brake Shoe

Use ceramic fibers and non-ferrous fillers to deliver stable friction performance, low noise, and reduced brake dust. They are suitable for selected passenger cars and specialty applications where comfort, clean braking, and consistent performance are preferred.

Brake Shoe Factory

Founded in 2009, our factory specializes in manufacturing brake shoes and brake pads for the global aftermarket, supplying customers across various regions.

Our factory covers 50,000 square meters and is operated by a skilled team with long-term production experience. Their familiarity with materials, tooling, and process control allows us to maintain consistent product quality, reliable output, and efficient delivery schedules.

As a brake shoe supplier, we understand what matters most to you, and we are always ready to work with you and help grow your business.

How We Produces OE-Quality Brake Shoes?

Strong manufacturing. Reliable performance. Consistent quality.

Steel Shoe Web Forming

The process starts with high-strength steel plates, which are cut, pressed, and formed into the brake shoe web.

This steel frame determines the brake shoe’s structural strength and fitment accuracy.

Heat Treatment

To improve rigidity and fatigue resistance, the formed steel shoe web may undergo heat treatment.

- Enhances strength and durability

- Reduces deformation under braking pressure

Surface Treatment of the Shoe Web

The steel shoe web is treated to prevent corrosion and improve appearance.

- Shot blasting or sand blasting (surface cleaning)

- Anti-rust coating or painting

- Phosphate or electrocoating

Friction Material Preparation

We produce brake linings using carefully selected friction formulations developed for aftermarket use. The material is mixed, molded, and cured under controlled temperature and pressure to achieve stable friction and reliable wear performance.

Lining Attachment

The cured lining is securely fixed to the shoe web using high-strength bonding, heavy-duty riveting, or a combined method, depending on application requirements. This ensures the lining remains firmly in place throughout its service life.

Precision Grinding & Finishing

Each brake shoe is ground to the correct thickness and arc radius. This allows proper contact with the brake drum, smoother engagement, and more even wear from the first stop.

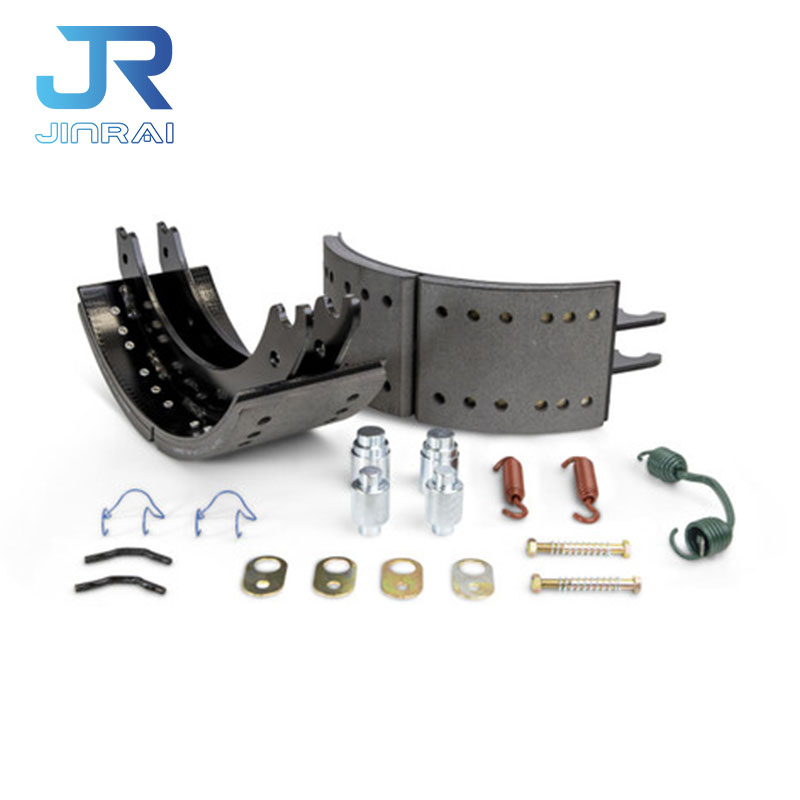

Assembly

For certain applications, we assemble brake shoes with springs, levers, or adjusters, supplying complete sets ready for installation.

Quality Inspection & Testing

Each batch goes through strict inspections, such as: dimensional checks, bonding or rivet strength testing, lining thickness measurement, visual inspection for defects. Only qualified products proceed to packing.

Packaging & Shipment

Brake shoes are packed according to your order requirements: neutral packaging, brand packaging, or customized labeling. Orders are then prepared for shipment with stable lead times and bulk consistency.

Our Main Markets

North America

America, Canada, Mexico, Guatemala, El Salvador, Honduras, Costa Rica, Panama

South America

Colombia, Venezuela, Suriname, Ecuador, Peru, Bolivia, Brazil, Argentina, Chile

Europe

Finland, Poland, UK, France, Malta, Spain, Portugal, Andorra, Sweden, Belarus, Monaco

Africa

Egypt, Libya, Sudan, Tunisia, Algeria, Morocco, Kenya, Tanzania, Uganda, Gabon, Burkina Faso, Nigeria, Cape Verde, Côte d’Ivoire, Ghana, Zambia, Angola, Zimbabwe, Malawi, South Africa, Madagascar

Asia

South Korea, Japan, Philippines, Vietnam, Laos, Cambodia, Myanmar, Thailand, Malaysia, Indonesia, Bangladesh, India, Pakistan, Sri Lanka, Iraq, Iran, Syria, Jordan, Lebanon, Israel, Palestine, Saudi Arabia, Bahrain, Qatar, Kuwait, United Arab Emirates, Oman, Yemen, Turkey

Why Choose Us?

As a brake shoe factory with rich experience, we provide full support to help you grow your business with ease.

OE Quality

Make production according to OE standards

Competitive Price

Give you factory direct selling prices

Lower MOQ

100sets each model

OEM&ODM

Support do your customized brand package

Warranty

1 Year after you receive our products

Your challenge VS Our solution

We understand your challenges, so we’ve built solutions for you

Your Challenge with old supplier

- Difficult Communication With Suppliers

“Working with some suppliers is frustrating. They often don’t fully understand my requirements, seem unfamiliar with the products, and take a long time to respond. This slows everything down.”

- Delivery Delays and Broken Promises

“Late delivery is a big problem with some suppliers. The shipping date keeps changing, and it causes trouble for my business. It’s honestly frustrating.”

- Receiving Low or Unstable Quality Products

“Sometimes when I receive the goods, the quantities are incomplete. Even worse, after I sell them to my customers, quality issues lead to complaints and returns. This happens far too often and causes serious trouble for my business.”

- Poor After-Sales Support

“When problems come up and I turn to the supplier for help, they avoid the issue and show no real willingness to solve it. I’m left dealing with angry customers by myself, which is incredibly discouraging.”

Our Solution

- Good Communication

Our sales team knows our products inside and out. We serve customers from over 80 countries, so language is never a barrier. We respond quickly, communicate clearly, and ensure you have the support you need.

- Fast Delivery on Time

Our monthly production capacity reaches 200,000 sets, allowing us to deliver your orders on time, in full, and with consistent quality.

- Only Produce OE Quality Products

Our brake shoes undergo strict quality testing both during production and before shipment, ensuring that every product you receive meets the highest standards.

- Excellent After-Sales Service

We take your feedback seriously. Within a 1-year warranty, if any quality issues arise, you can contact us at any time, and we will work with you to resolve them and compensate you promptly.

More Than A Supplier, Your Trusted Partner

Together with our clients, we build stronger markets through trust, quality, and long-term cooperation.

Every year, we participate in major exhibitions such as Automechanika Las Vegas, Mexico, Dubai, Shanghai, and the Canton Fair to meet our customers in person and gain firsthand insight into their market needs.

We warmly invite customers to tour our factory. Witnessing our production process, quality checks, and team in action helps build trust and confidence for long-term cooperation.

Beyond the typical buyer-supplier relationship, we see our customers as friends. We talk about life, daily experiences, and even future plans, building a genuine connection that goes beyond business.

Frequently Asked Questions

Everything you want to know about working with us — answered here.

Are you a manufacturer or a trading company?

What is Your MOQ?

Do you offer customized packaging and branding?

What is your warranty policy?

What payment terms do you accept?

Contact Us

You can send us your inquiry lists, requirements, or suggestions using the following form. We will reach you asap.