Wholesale Car Bushing Manufacturer

OE Quality | Factory Pricing | Support Customized Brand

Car Bushing Manufacturer in China

Anhui Goldenstar Auto Parts is a professional car bushing manufacturer specializing in high-quality rubber components for the automotive aftermarket, including bushings, strut mounts, engine mounts, and more.

With over 2,000 suspension bushing models developed, such as control arm bushings, stabilizer bar bushings, and sway bar bushings, we cover a wide range of vehicles from Japanese, European, and American car brands.

As a factory, we offer a unique advantage for customers looking to customize their own brand packaging. From design to packaging, we can help you create a brand that stands out, all at competitive prices that boost your market edge.

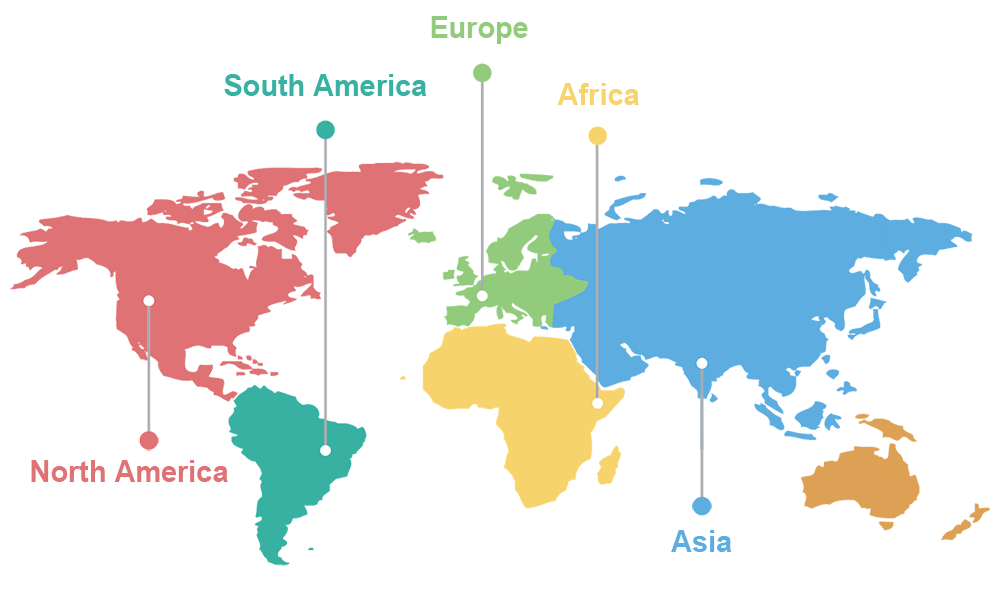

Our products are trusted by customers in over 100 countries, spanning South America, North America, Europe, the Middle East, Africa, and Southeast Asia. With our rich experience and strong manufacturing capabilities, we are ready to help your business grow and succeed.

Partner with Goldenstar Auto Parts, and let us help you bring high-quality rubber components and your brand vision to the global market.

Our Car Bushings Advantages

- Durable Rubber Material

Made from premium natural rubber compounds that resist wear, heat, and aging. - Precision Fit

Make production according to OE standards, providing a perfect fit and stable suspension performance. - Vibration & Noise Reduction

Effectively absorbs shocks and road vibrations, improving driving comfort and stability. - Corrosion & Chemical Resistance

Resistant to oil, grease, and other chemicals commonly found in engine and suspension systems. - Consistent Performance

Every bushing undergoes strict quality control to guarantee uniformity and reliability.

Our Car Bushings Application

What you need is exactly what we offer.

Japanese vehicles

Toyota, Honda, Nissan, Mazda, Subaru, Mitsubishi, Suzuki, Isuzu, Hino, Daihatsu

Korean Vehicles

Hyundai, Kia, Genesis, SsangYong

European Vehicles

DAF, Renault, Peugeot, Citroën, Fiat, Iveco, Volvo, Scania, Land Rover

American Vehicles

Ford, Chevrolet, Dodge, Tesla, Jeep, Cadillac, Buick

German Vehicles

Volkswagen, BMW, Audi, Porsche, Mercedes-Benz, MAN, Opel

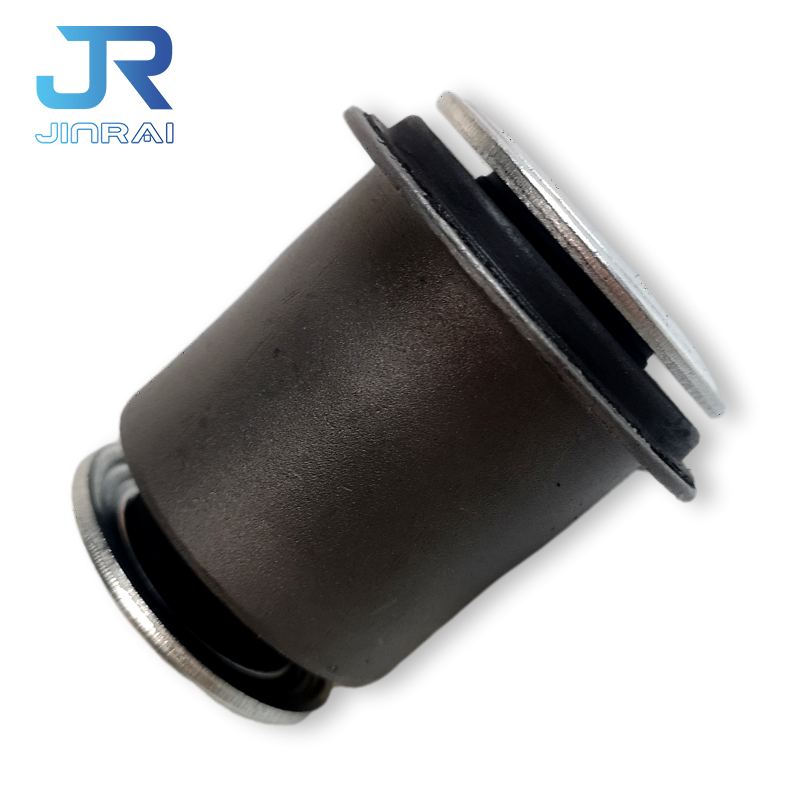

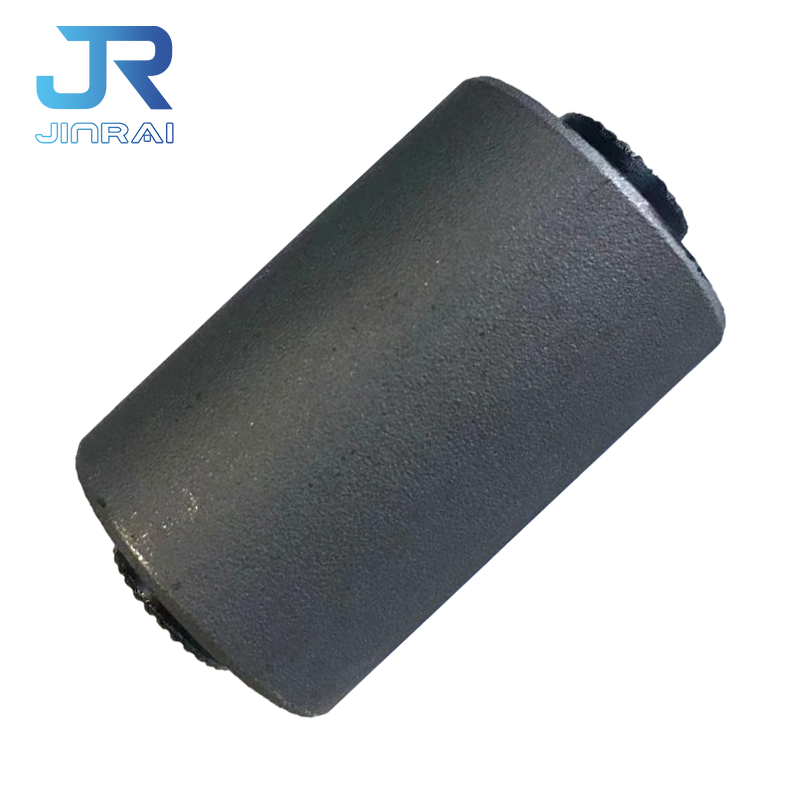

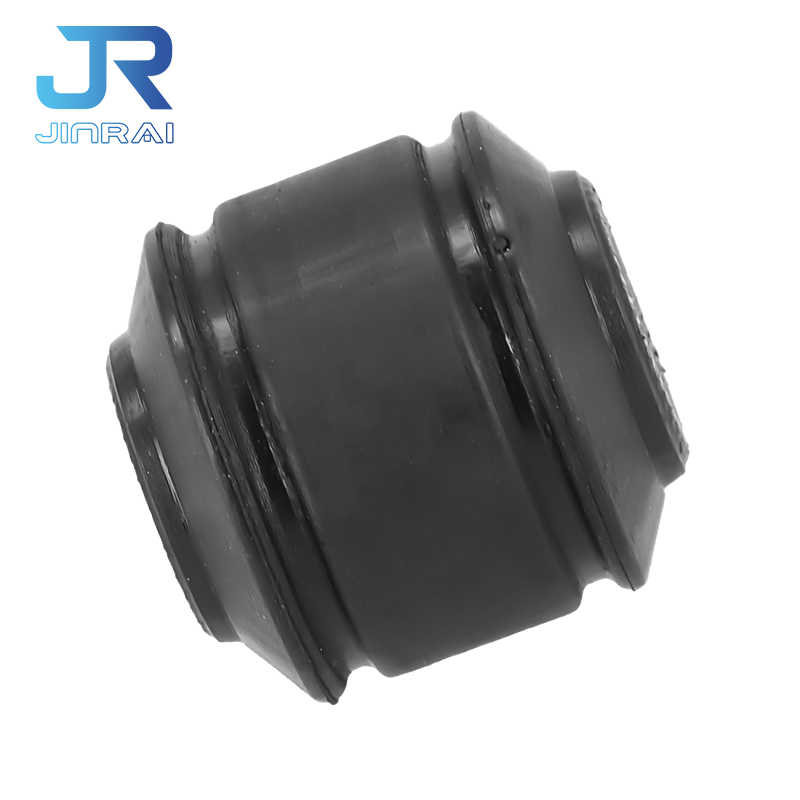

Type of Our Car bushings

Control Arm Bushing

Installed at the connection points between the control arm and the chassis or subframe.

Shock Absorber Bushing

Found at the upper and lower mounting points of the shock absorber.

Sway Bar Bushing

Mounted between the sway bar (stabilizer bar) and the vehicle frame or subframe.

Axle Bushing

Located between the axle and the vehicle frame or suspension bracket.

Leaf Spring Bushing

Positioned at both ends of the leaf spring, where it connects to the chassis and shackle.

Torque Rod Bushing

Located at both ends of the torque rod, connecting the axle to the chassis.

Car Bushing Factory

Founded in 2000, our factory has over 20 years of experience in manufacturing and exporting high-quality rubber components, specializing in car bushings, strut mounts, engine mounts, and other suspension parts.

Equipped with more than 20 production and testing machines and supported by over 120 skilled workers, we maintain a monthly output of around 200,000 bushings, ensuring reliable supply and consistent quality for every order.

With streamlined production and logistics, we can provide a stable delivery timeline of 30–45 days, helping you meet your schedule and satisfy your customers.

We are committed to producing durable, precise, and high-performing car bushings that support your business growth. Partner with us, and let’s drive your success together.

How We Produces OE-Quality Car Bushings?

Strong manufacturing. Reliable performance. Consistent quality.

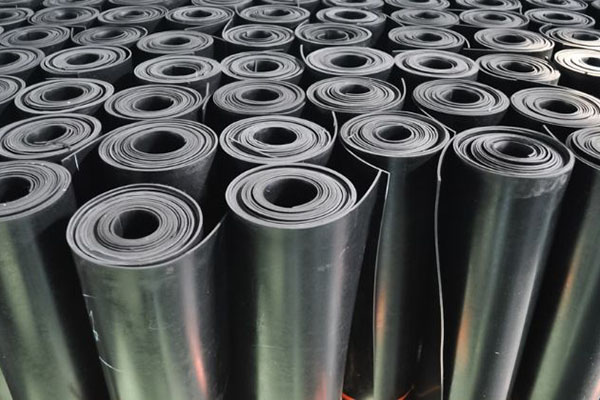

Material Selection

High-quality car bushings start with carefully selected rubber compounds. We use durable rubber materials with excellent resistance to wear, heat, and aging, ensuring stable performance under different road and climate conditions.

Precise Rubber Mixing & Compounding

The rubber is mixed according to strict formulas to achieve the right balance of elasticity, strength, and durability.

This step is critical to ensure consistent performance from batch to batch.

Mold Design & Preparation

Each bushing is produced using precision molds designed to match OEM specifications. This guarantees accurate dimensions, proper fitment, and reliable suspension performance.

Vulcanization & Forming

Through controlled temperature and pressure, the rubber is vulcanized and molded into shape. This process strengthens the rubber structure and ensures long service life.

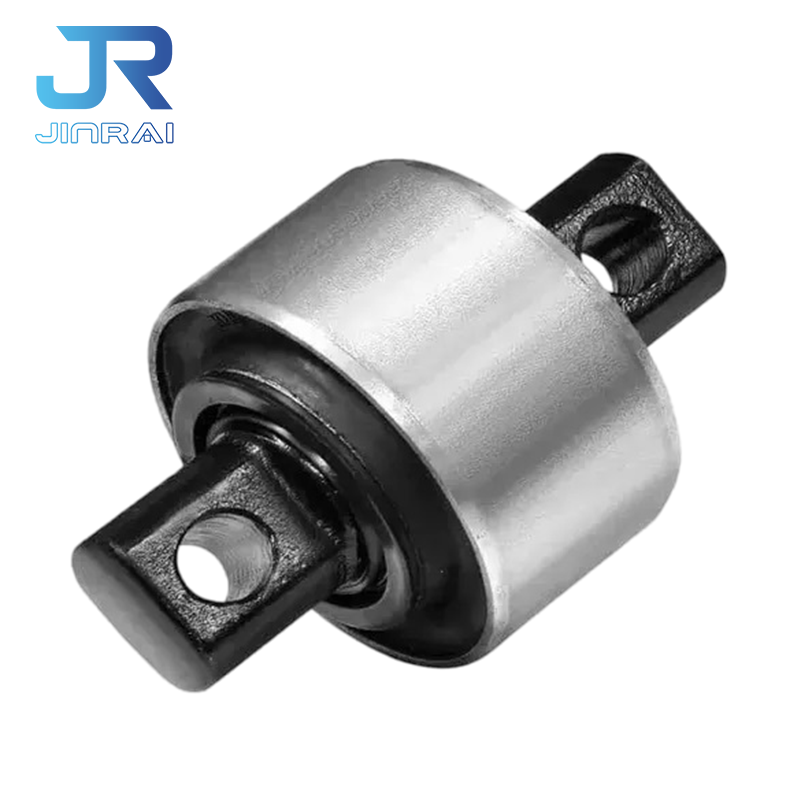

Metal Bonding

For bushings with metal sleeves, rubber and metal components are securely bonded to ensure strong adhesion and durability during long-term use.

Trimming & Surface Finishing

After molding, excess rubber is carefully trimmed and surfaces are finished to meet appearance and performance standards.

Dimensional & Performance Inspection

Each car bushing is inspected for dimensions, appearance, and performance to ensure it meets quality requirements before packaging.

Packaging & Delivery

- Neutral packaging

- Customized brand packaging

- Barcode and labeling support

Designed for safe transport and efficient distribution.

Our Main Markets

North America

America, Canada, Mexico, Guatemala, El Salvador, Honduras, Costa Rica, Panama

South America

Colombia, Venezuela, Suriname, Ecuador, Peru, Bolivia, Brazil, Argentina, Chile

Europe

Finland, Poland, UK, France, Malta, Spain, Portugal, Andorra, Sweden, Belarus, Monaco

Africa

Egypt, Libya, Sudan, Tunisia, Algeria, Morocco, Kenya, Tanzania, Uganda, Gabon, Burkina Faso, Nigeria, Cape Verde, Côte d’Ivoire, Ghana, Zambia, Angola, Zimbabwe, Malawi, South Africa, Madagascar

Asia

South Korea, Japan, Philippines, Vietnam, Laos, Cambodia, Myanmar, Thailand, Malaysia, Indonesia, Bangladesh, India, Pakistan, Sri Lanka, Iraq, Iran, Syria, Jordan, Lebanon, Israel, Palestine, Saudi Arabia, Bahrain, Qatar, Kuwait, United Arab Emirates, Oman, Yemen, Turkey

Why Choose Us?

As a car bushing factory with rich experience, we provide full support to help you grow your business with ease.

OE Quality

Make production according to OE standards

Competitive Price

Give you factory direct selling prices

Lower MOQ

100pcs each model

OEM&ODM

Support do your customized brand package

Warranty

1 Year after you receive our products

Your challenge VS Our solution

We understand your challenges, so we’ve built solutions for you

Your Challenge

- Difficult Communication With Suppliers

“Communication with my previous suppliers was often inefficient. Slow replies, unclear information, and frequent misunderstandings made it difficult to move forward with confidence.”

- Delivery Delays and Broken Promises

“Unreliable delivery schedules create serious risks. Orders are confirmed with a promised delivery date, but last-minute delays happen too often. These disruptions impact my operations, lead to customer complaints, and hurt my credibility”

- Receiving Low or Unstable Quality Products

“With my previous suppliers, quality was never truly consistent. Some products worked perfectly, but others had issues far too early. I ended up handling returns, complaints, and unexpected costs.”

- Poor After-Sales Support

“Whenever a problem occurs, some suppliers simply go quiet. Replies become slow, responsibility is pushed aside, and no real solution is offered. In the end, I’m left dealing with customer complaints, covering the losses, and protecting my reputation on my own.”

Our Solution

- Good Communication

Having served customers in over 100 countries, we communicate clearly and efficiently, with no language or cultural barriers. Our experienced team provides professional, easy-to-understand guidance and responds promptly to all inquiries.

- Fast Delivery on Time

Our delivery reliability is built on real production capacity. With a stable monthly output of around 200,000 pcs, we schedule every order based on actual machine load and workforce availability. Combined with a clearly defined 30-45day production cycle.

- Only Produce OE Quality Products

We ensure quality through strict control of materials, production processes, and in-process inspections to prevent defects. Every batch is fully traceable, and if any issue arises, our quality team takes immediate corrective action to resolve it and prevent recurrence.

- Excellent After-Sales Service

When an issue occurs, we act quickly to investigate and fix it, keeping you updated throughout. Our goal is to protect your business, limit any impact, and make sure you feel supported and confident in our partnership.

More Than A Supplier, Your Trusted Partner

Together with our clients, we build stronger markets through trust, quality, and long-term cooperation.

Each year, we participate in major automotive exhibitions around the world, including Las Vegas, Mexico, Dubai, Shanghai, and the Canton Fair. These events allow us to present our products directly, connect with customers face-to-face, and gain first-hand insights into global market trends.

Visiting our factory gives customers a direct look at how we manage production, maintain consistent quality, and coordinate as a team. Seeing our operations in action provides confidence in our professionalism and the dependability of a long-term business relationship.

Our customers are more than business contacts — they are collaborators we grow with. Through open conversations, shared experiences, and working closely together, we build trust, understand each other’s needs, and create partnerships that feel as close as friendship.

Frequently Asked Questions

Everything you want to know about working with us — answered here.

Are you a manufacturer or a trading company?

What is Your MOQ?

Do you offer customized packaging and branding?

What is your warranty policy?

What payment terms do you accept?

Contact Us

You can send us your inquiry lists, requirements, or suggestions using the following form. We will reach you asap.