Wholesale Clutch Disc Manufacturer

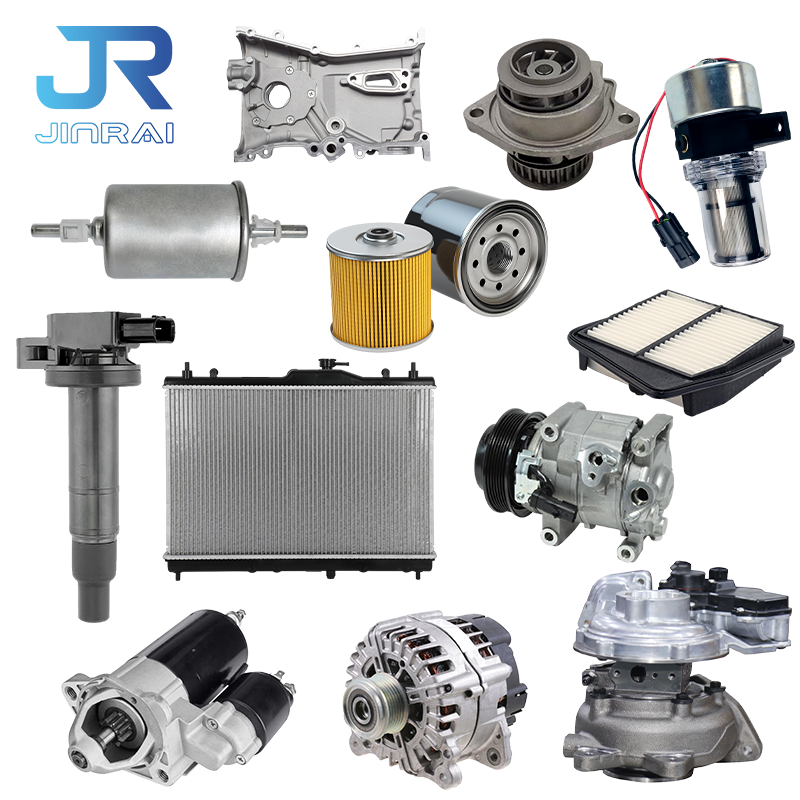

Factory-Direct Supply | Consistent OE Quality | Full Range

Clutch Disc Manufacturer in China

Anhui Goldenstar Auto Parts is a professional clutch disc manufacturer serving the global aftermarket with OE-quality clutch kits, including clutch discs and clutch pressure plates.

For many years, we have focused on one thing only — manufacturing reliable clutch discs that customers can trust. This long-term focus allows us to control materials, processes, and quality details that directly affect performance and service life.

Today, we offer over 1,000 clutch disc models, covering passenger cars, light-duty and heavy-duty trucks, as well as buses, for American, European, Japanese, and Korean vehicles. Our products are designed for stable engagement, consistent friction performance, and dependable batch-to-batch quality.

To support distributors and brand owners, we provide customized packaging solutions, including color bags, color boxes, and private labels. These services help our partners build strong, recognizable brands in their local markets.

So far, we have helped more than 100 customers worldwide establish and grow their clutch product lines. If you are looking for a clutch disc supplier that understands margin control, supply stability, and long-term cooperation, Anhui Goldenstar Auto Parts is ready to work with you.

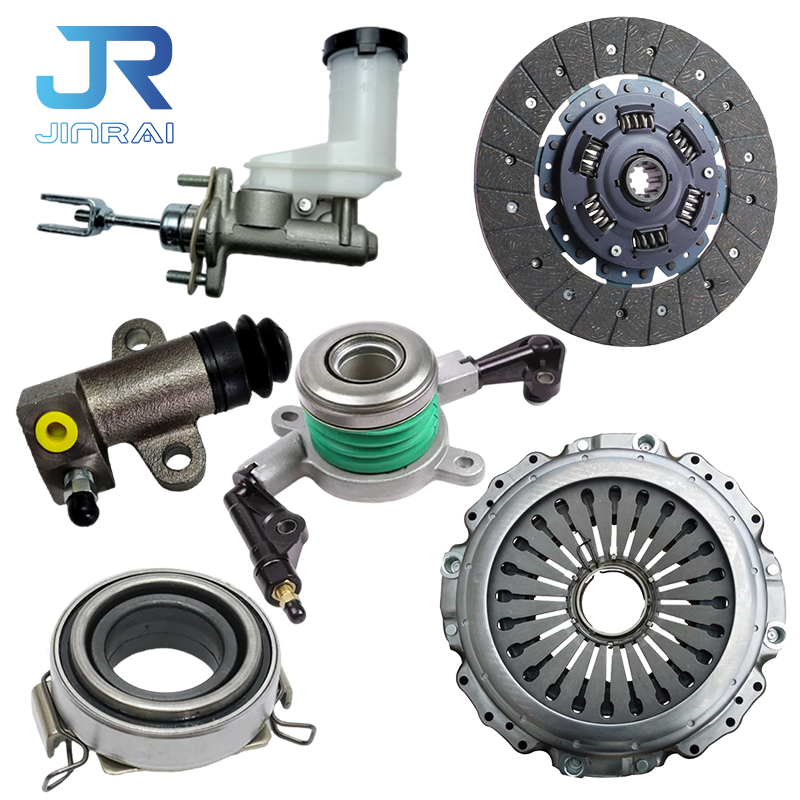

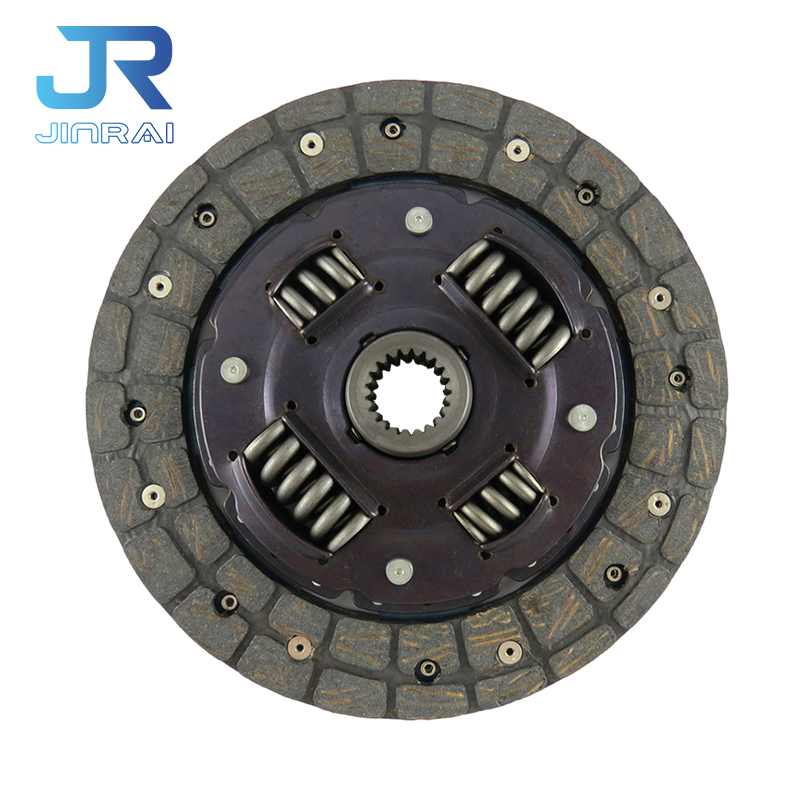

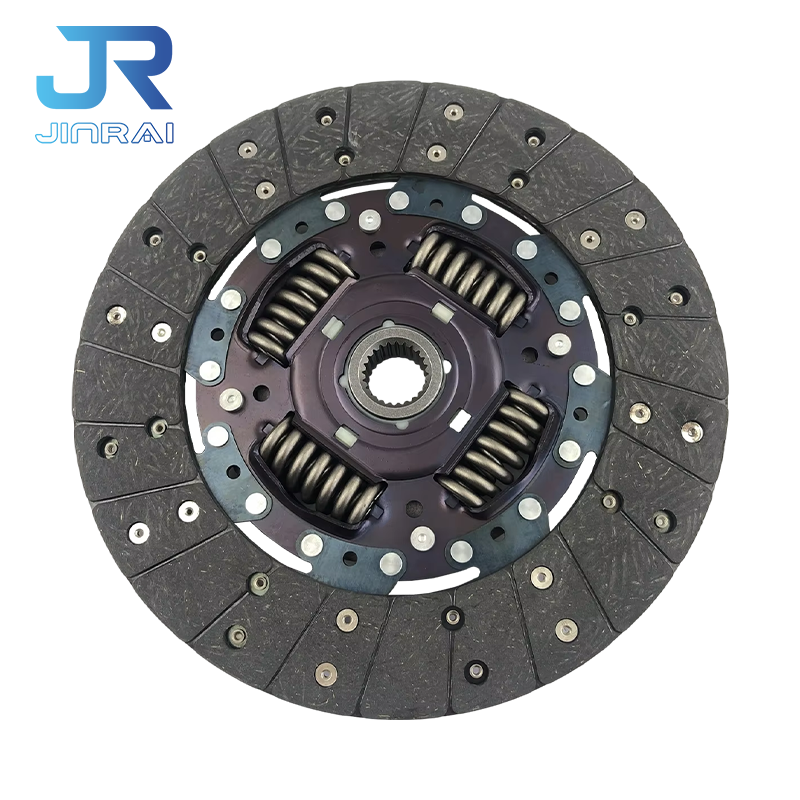

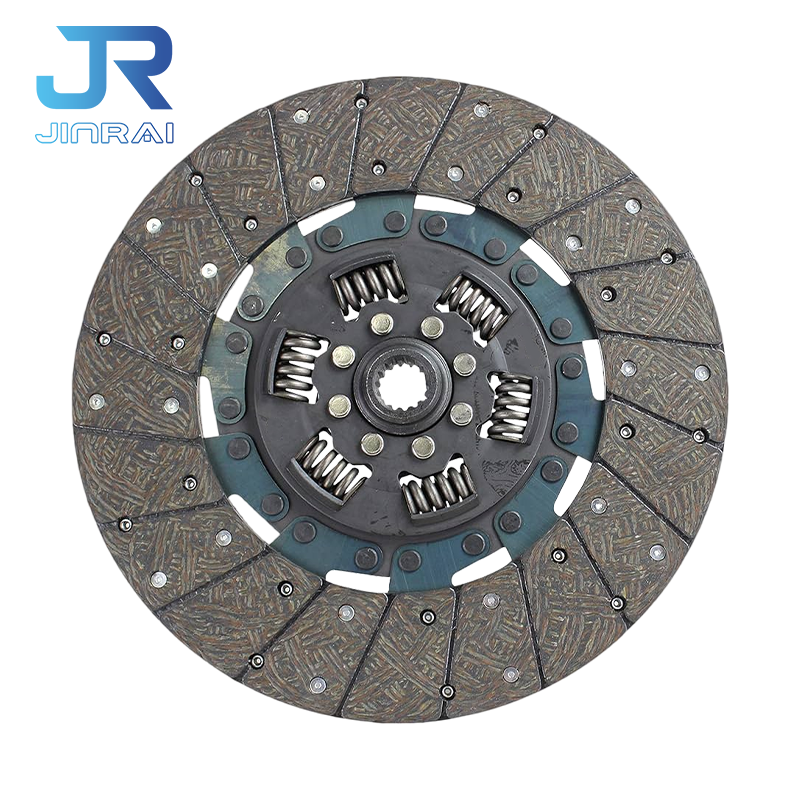

Our Clutch Discs

OE-Quality Clutch Discs for the Aftermarket

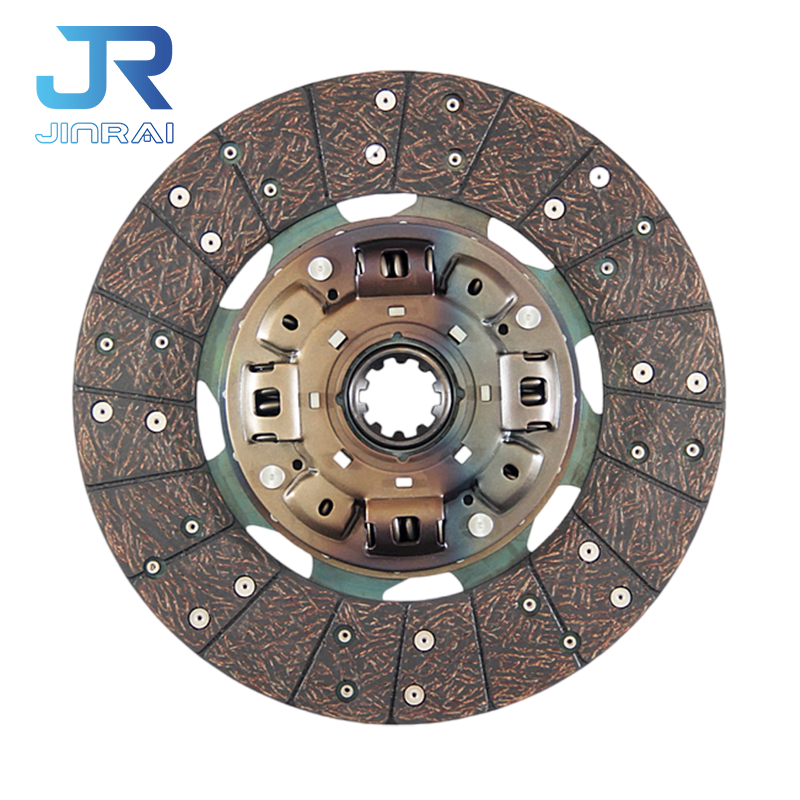

As a professional clutch disc manufacturer, we only produce high-quality clutch discs with stable performance and long service life for the aftermarket.

- Stable Organic Friction Material

Maintains consistent friction under high temperatures and extends service life. - Smooth Engagement & Responsive Shifting

Balanced friction design reduces judder and improves shift feel. - Heavy-Duty Torsion Springs

Absorb drivetrain shock, reduce noise, and improve driving comfort. - Reinforced Steel-Backed Structure

Enhances strength and reliability under high load conditions. - Precision Machined Hub & Splines

Ensures accurate fit and stable torque transmission. - Heat-Treated Critical Components

Improves durability and resistance to deformation over time.

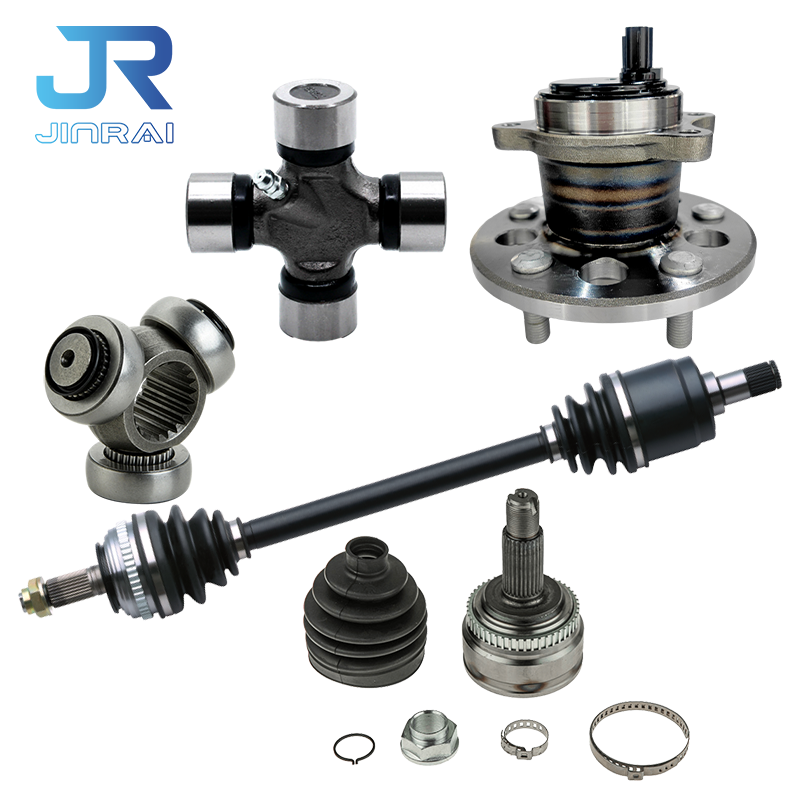

Our Clutch Discs Application

What you need is exactly what we offer.

Japanese vehicles

Toyota, Honda, Nissan, Mazda, Subaru, Mitsubishi, Suzuki, Isuzu, Hino, Daihatsu

Korean Vehicles

Hyundai, Kia, Genesis, SsangYong

European Vehicles

DAF, Renault, Peugeot, Citroën, Fiat, Iveco, Volvo, Scania, Land Rover

American Vehicles

Ford, Chevrolet, Dodge, Tesla, Jeep, Cadillac, Buick

German Vehicles

Volkswagen, BMW, Audi, Porsche, Mercedes-Benz, MAN, Opel

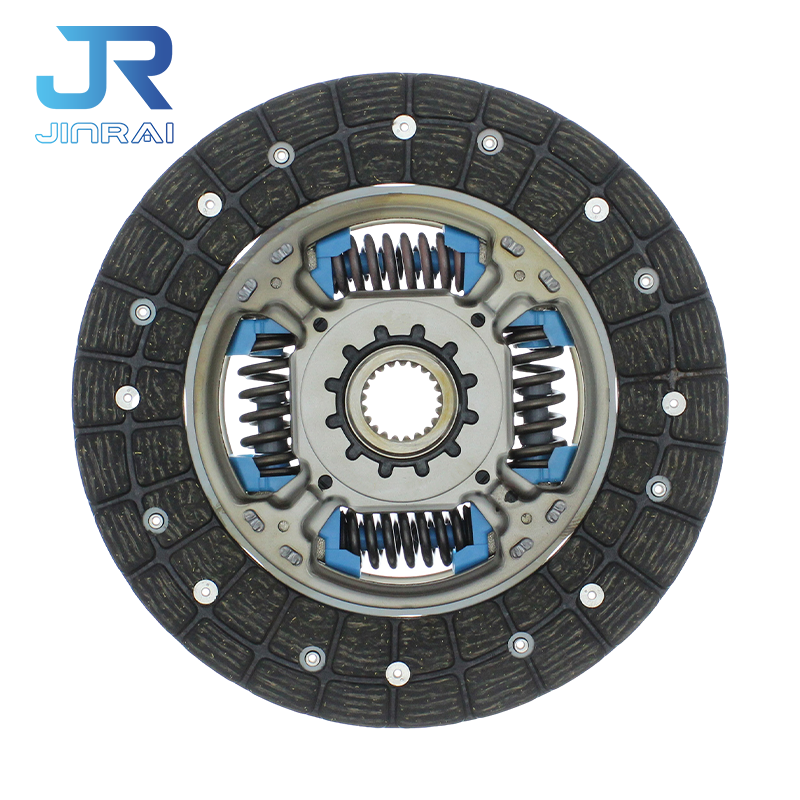

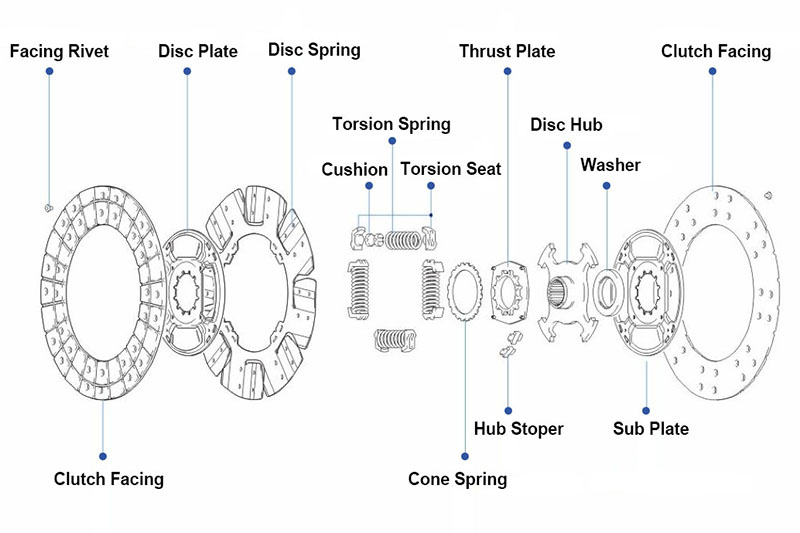

Main Parts of a Clutch Disc

Each component of our clutch disc assembly is manufactured with strict quality control to ensure stable performance and long service life:

Friction linings – create grip with the flywheel and pressure plate

Torsion springs – absorb vibration and reduce drivetrain shock

Steel core plate – maintains strength and stability

Hub & splines – connect the disc to the transmission shaft

Together, these high-quality parts play crucial roles in ensuring a smooth power transfer and a long service life.

what is a clutch disc?

A clutch disc is one of the most important components in a vehicle’s clutch system.

It sits between the engine and the transmission. When you press the clutch pedal, the clutch disc disconnects the engine from the transmission.

When the pedal is released, the clutch disc reconnects them, allowing the vehicle to move.

function of clutch disc

The main function of a clutch disc is to transfer engine power to the transmission smoothly.

- Start the vehicle smoothly

- Shift gears easily

- Control power connection between the engine and gearbox

- Absorb vibration and reduce shock, protect the transmission, and improve driving comfort.

bad clutch disc symptoms

- Clutch slipping – engine speed rises but vehicle acceleration is weak

- Hard gear shifting – gears feel difficult to engage

- Shudder or vibration – shaking when starting from a stop

- Burning smell – caused by overheating from slipping

- Loss of acceleration – poor power delivery, especially under load

- Abnormal noise – unusual sounds during clutch operation

Clutch Disc Factory

Founded in 2000, our factory has been focused on the manufacturing of clutch discs for the global aftermarket. From the beginning, our goal has been simple — to supply reliable, OE-quality clutch discs that support stable long-term cooperation.

Our production base covers over 50,000 ㎡ and is operated by more than 230 experienced workers. With a monthly output of up to 160,000 pcs clutch discs, we can maintain consistent quality standards while ensuring reliable supply for wholesale and repeat orders.

By working directly with us as a manufacturer, you will gain not only stable products but also the production capacity and supply reliability needed to stay competitive in fast-moving aftermarket markets.

How We Produces OE-Quality Clutch Discs?

Strong manufacturing. Reliable performance. Consistent quality.

Material Selection

Every clutch disc starts with carefully selected materials, including friction linings, high-strength steel core plates, damper springs, and fastening components.

All materials are inspected for strength, consistency, and dimensional accuracy before entering production, ensuring stable performance from the beginning.

Steel Core Plate Stamping

The steel core plate is stamped using precision tooling to form the structural backbone of the clutch disc. Key controls at this stage include:

- Accurate dimensions

- Consistent spline positioning

- Stable concentricity

This guarantees proper fitment and smooth power transmission after installation.

Friction Lining Forming

Through controlled mixing, high-pressure molding, and curing, the friction linings achieve:

- Stable friction coefficient

- Strong wear resistance

- Reliable heat tolerance

This directly affects clutch engagement feel and service life.

Riveting & Assembly

The friction linings are firmly riveted onto both sides of the steel core plate.

Precise riveting ensures:

- Tight bonding

- No looseness at high speed

- Even wear during operation

Damper Spring Installation

The damper spring system is assembled at the disc center to absorb torque shocks. This helps:

- Reduce vibration and noise

- Improve shifting comfort

- Protect the transmission system

Spring specifications are matched according to torque requirements.

Dynamic Balancing & Precision Control

Each clutch disc undergoes dynamic balancing and runout inspection.

This ensures stable rotation at high RPMs with:

- No abnormal vibration

- No uneven wear

- Consistent driving performance

Performance Testing & Final Inspection

Finished clutch discs are tested for:

- Torque capacity

- Heat resistance

- Durability under load

- Dimensional accuracy

Only products that pass all inspections move to packaging.

Packaging & Delivery

Clutch discs are packed according to customer needs, including:

- Neutral packaging

- Customized brand packaging

- Barcode and labeling support

Designed for safe transport and efficient distribution.

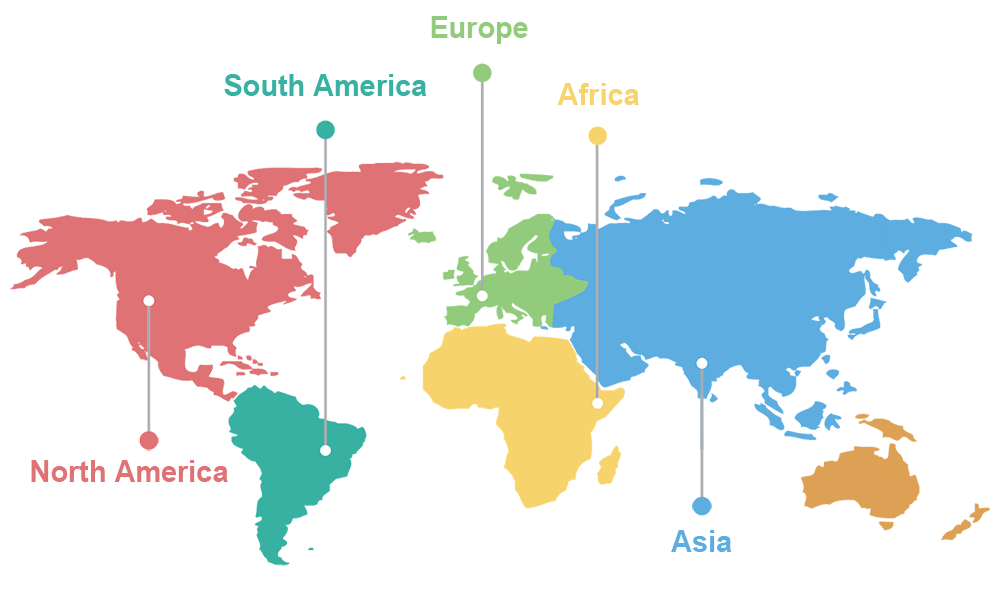

Our Main Markets

North America

America, Canada, Mexico, Guatemala, El Salvador, Honduras, Costa Rica, Panama

South America

Colombia, Venezuela, Suriname, Ecuador, Peru, Bolivia, Brazil, Argentina, Chile

Europe

Finland, Poland, UK, France, Malta, Spain, Portugal, Andorra, Sweden, Belarus, Monaco

Africa

Egypt, Libya, Sudan, Tunisia, Algeria, Morocco, Kenya, Tanzania, Uganda, Gabon, Burkina Faso, Nigeria, Cape Verde, Côte d’Ivoire, Ghana, Zambia, Angola, Zimbabwe, Malawi, South Africa, Madagascar

Asia

South Korea, Japan, Philippines, Vietnam, Laos, Cambodia, Myanmar, Thailand, Malaysia, Indonesia, Bangladesh, India, Pakistan, Sri Lanka, Iraq, Iran, Syria, Jordan, Lebanon, Israel, Palestine, Saudi Arabia, Bahrain, Qatar, Kuwait, United Arab Emirates, Oman, Yemen, Turkey

Why Choose Us?

As a clutch disc factory with rich experience, we provide full support to help you grow your business with ease.

OE Quality

Make production according to OE standards

Competitive Price

Give you factory direct selling prices

Lower MOQ

100pcs each model

OEM&ODM

Support do your customized brand package

Warranty

1 Year after you receive our products

Your challenge VS Our solution

We understand your challenges, so we’ve built solutions for you

Your Challenge

- Difficult Communication With Suppliers

“I often have to repeat my requirements multiple times, yet many suppliers still respond unclearly or too late. Order updates are missing, communication is inconsistent, and misunderstandings are common — resulting in delays, errors, and unnecessary time costs on my side.”

- Delivery Delays and Broken Promises

“Delivery delays are one of the biggest risks I face with unreliable suppliers. A delivery date is confirmed, I align my plans accordingly, and then it gets postponed at the last minute. This disrupts my operations, creates pressure from my customers, and damages my credibility — even though the delay is beyond my control.”

- Receiving Low or Unstable Quality Products

“I’ve received batches with inconsistent quality — some parts work fine, while others fail far too quickly. This leaves me dealing with returns, complaints, and extra costs that shouldn’t have been my responsibility.”

- Poor After-Sales Support

“When a quality issue comes up, some suppliers simply disappear. Responses become slow, problems are avoided, and real solutions never come. In the end, I’m left absorbing the loss, handling customer complaints, and taking the damage to my reputation. It completely undermines my confidence in the supplier”

Our Solution

- Good Communication

Having served customers in over 100 countries, we ensure smooth communication with no barriers. With extensive experience and in-depth knowledge, we provide clear, professional guidance and are available around the clock to respond promptly to any questions or concerns.

- Fast Delivery on Time

We maintain a steady monthly output of approximately 160,000 pieces and operate on a clearly defined 55-day lead time. Our production capacity and planning discipline ensure on-time delivery as promised, helping you avoid delays, disruptions, and uncertainty in your supply chain.

- Only Produce OE Quality Products

From casting and machining to final assembly, every production step is completed in-house under strict supervision. We don’t just assemble the products, each clutch disc is individually tested before leaving our factory to ensure it meets OE standards.

- Excellent After-Sales Service

We take after-sales support seriously. Whenever an issue arises, we respond promptly, thoroughly investigate the situation, and work closely with you to reach a fair solution. We aim to minimize any impact on your business and ensure you feel fully supported, giving you confidence that we are always here to protect your interests.

More Than A Supplier, Your Trusted Partner

Together with our clients, we build stronger markets through trust, quality, and long-term cooperation.

With the capability to attend major automotive exhibitions across the globe each year — from Las Vegas and Mexico to Dubai, Shanghai, and the Canton Fair — we showcase our products, engage directly with customers, and stay closely attuned to international market demands, reflecting our strong global presence and industry expertise.

Customers are always welcome to visit our factory. Seeing our production lines, quality management, and teamwork in action allows you to experience our capabilities firsthand and strengthens confidence in a reliable, long-term business relationship.

We see our customers as more than clients. Beyond business transactions, we share ideas, meals, and experiences with them, learning from each other and growing together, which makes us understand their real needs, offer better solutions, and foster a partnership that feels as close and trustworthy as friendship.

Frequently Asked Questions

Everything you want to know about working with us — answered here.

Are you a manufacturer or a trading company?

What is Your MOQ?

Do you offer customized packaging and branding?

What is your warranty policy?

What payment terms do you accept?

Contact Us

You can send us your inquiry lists, requirements, or suggestions using the following form. We will reach you asap.