Offroad Shock Absorber Manufacturer

Factory Price | Extreme Performance | Ready to Ship

Offroad Shock Absorber Manufacturer in China

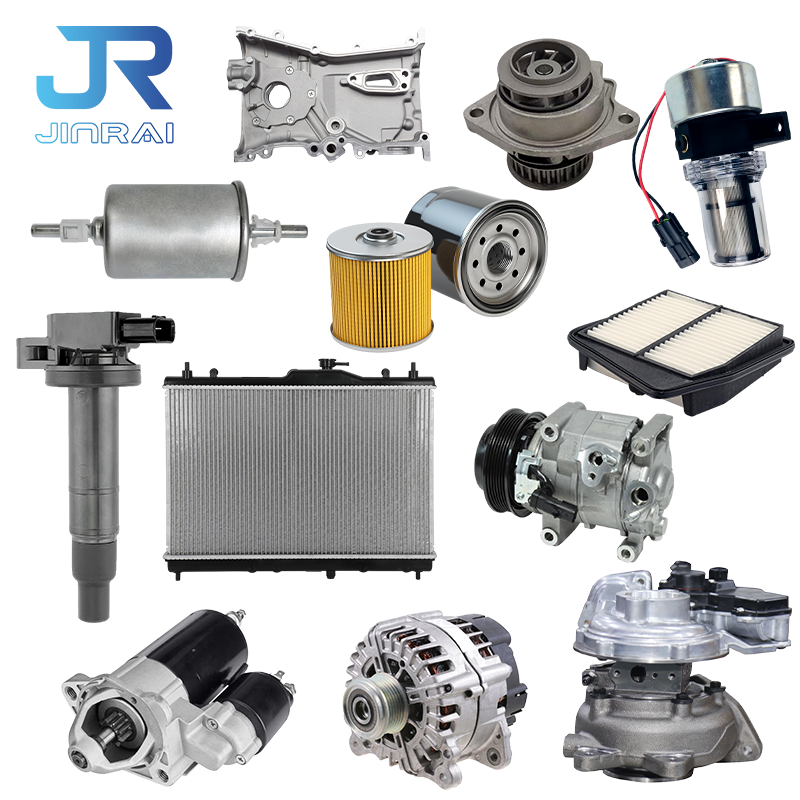

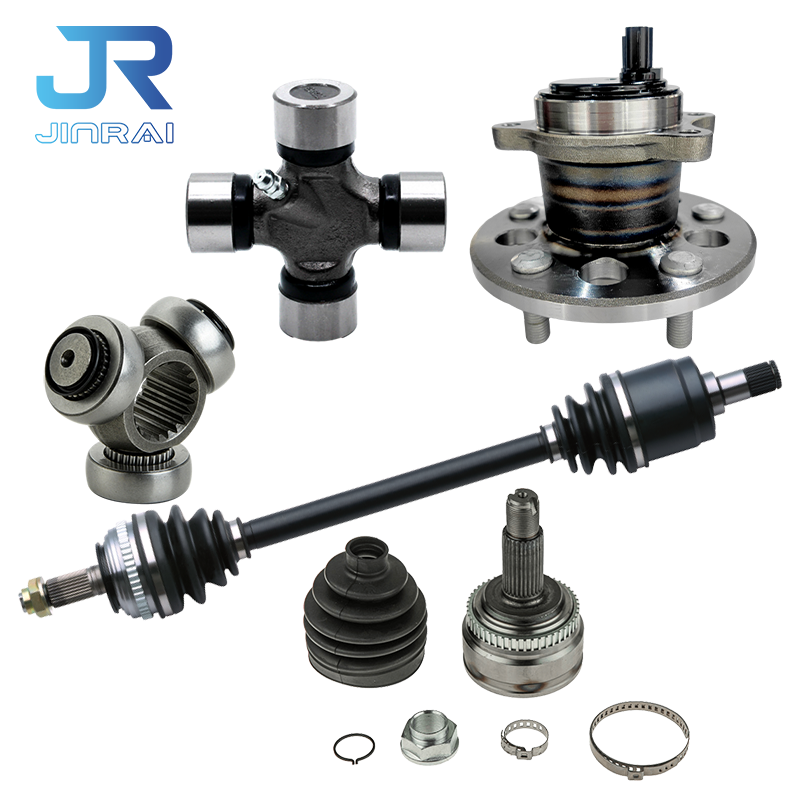

Anhui Goldenstar Auto Parts is a professional manufacturer specializing in off-road shock absorbers with over 20 years of experience. We offer a comprehensive range of 4×4 shocks, including adjustable and non-adjustable nitrogen shocks and oil dampers, engineered to enhance performance, stability, and comfort for all types of offroad vehicles.

Our 4×4 off-road shocks cover a wide variety of vehicles, including Toyota, Nissan, Mitsubishi, Ford, Chrysler, Isuzu, Baic, GM, Great Wall, Suzuki, Mazda, VW, JMC, LDV, Mercedes-Benz, Land Rover, and Sand/UTV/ATV/Buggy.

Whether you’re looking to upgrade your personal off-road vehicle—we can ship within 7 days for one set—or you’re a distributor seeking a reliable off-road shock absorber manufacturer with custom-branded packaging, we are ready to support your needs with flexibility and speed.

Don’t wait, contact us now for fast delivery and custom solutions! Our professional sales team are waiting for you!

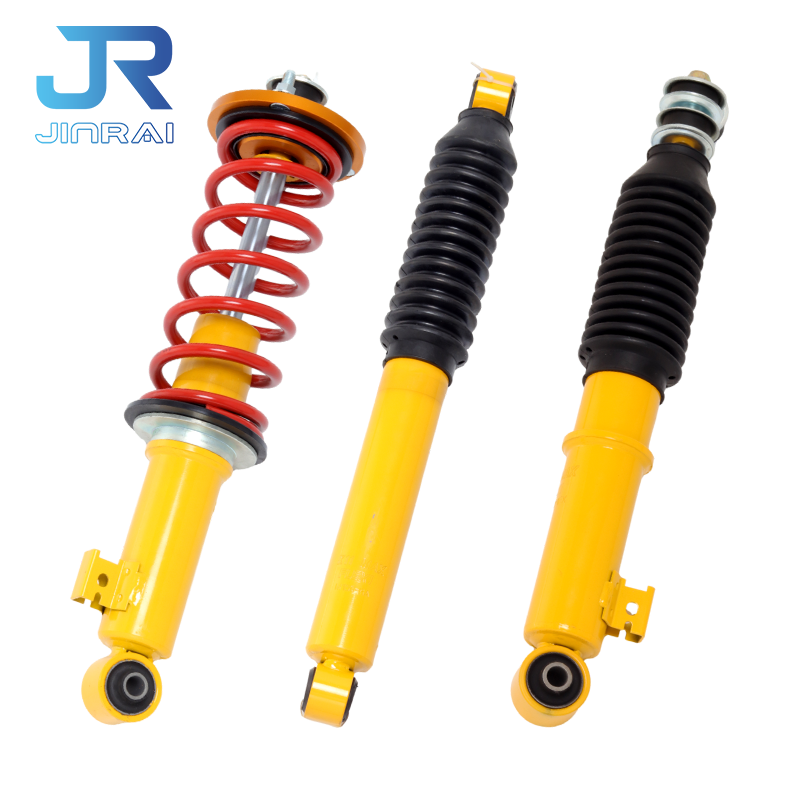

Kinds of Our 4x4 Shocks

oil Twin-tube shock

Non-adjustable

Oil Twin-Tube Shock

Adjustable

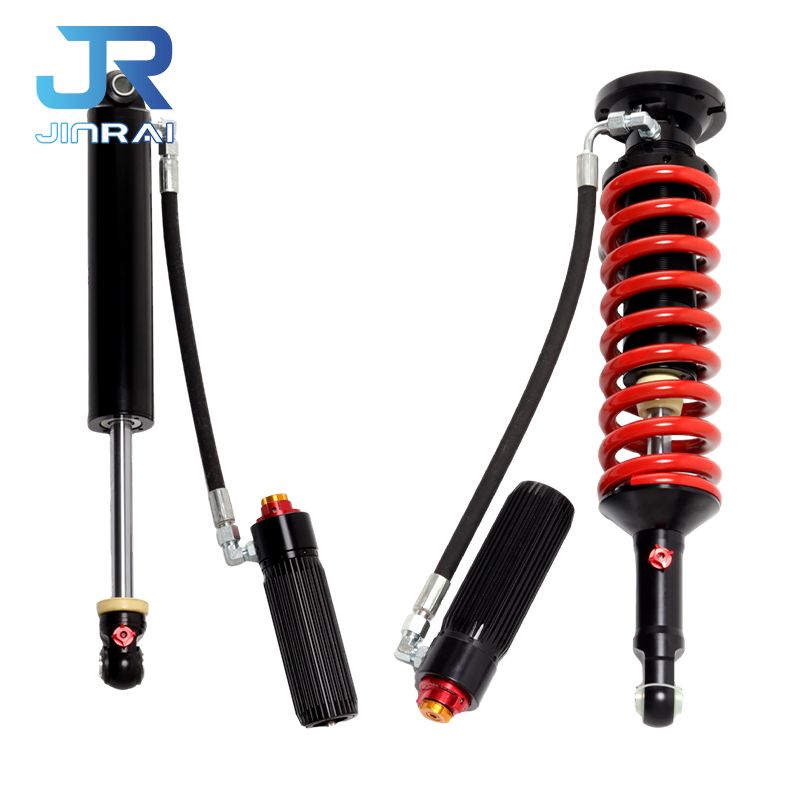

nitrogen monotube shock

- with a inside reservoir

- adjustable compression

nitrogen monotube shock

- with a remote reservoir

- adjustable compression

nitrogen monotube shock

- with a remote reservoir

- adjustable compression

- adjustable rebound

nitrogen monotube shock

- with a remote reservoir

- adjustable compression

- adjustable rebound

- adjustable high-and low-speed

nitrogen monotube shock

- with a remote reservoir

- Inside bump stop

- adjustable compression

- adjustable rebound

- adjustable high-and low-speed

Send Inquiry

Please let us know car models and years of vehicles, we will make a recommendation of 4×4 shocks for you.

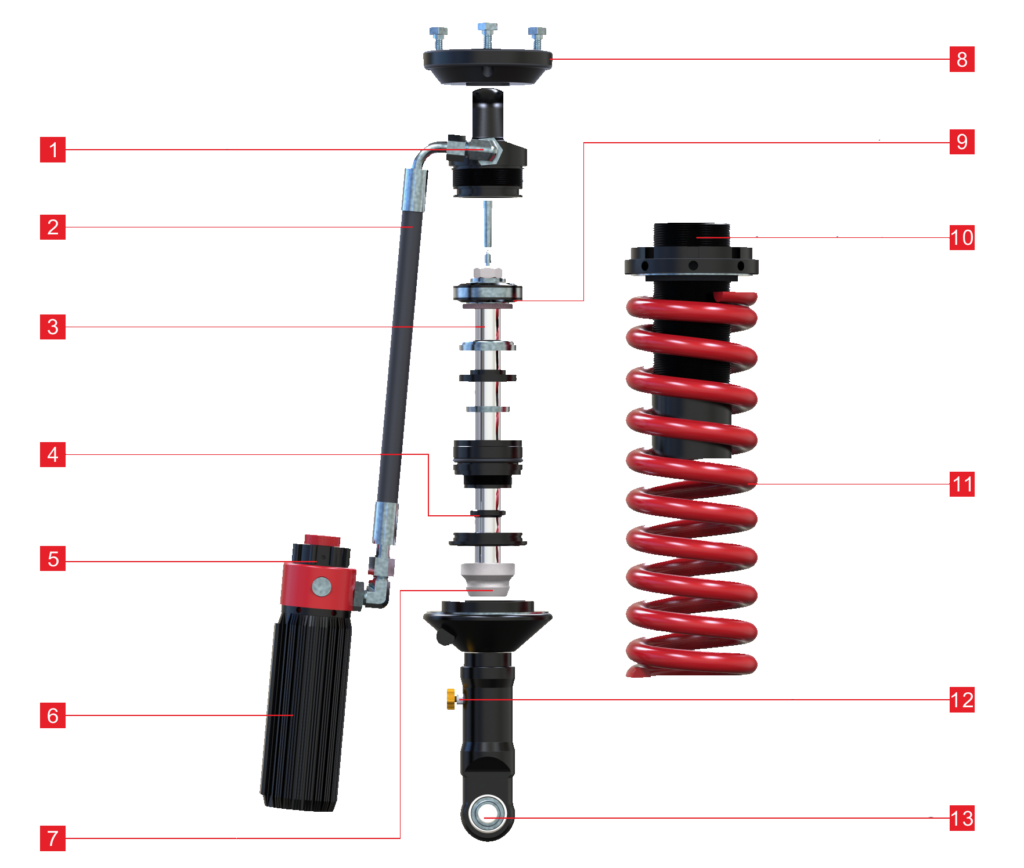

Performance Starts with the Details

Built for extreme off-road conditions, our 4×4 shock absorbers combine heavy-duty materials with premium components to deliver strong damping performance, long service life, and reliable control.

- 35CrMo piston rod

Twin-tube 20mm / Mono-tube 22mm — high strength and impact resistance - Reinforced steel body

Twin-tube 56mm / Mono-tube 2.25″ & 2.5″ — improved rigidity and heat dissipation - T6061 aluminum reservoir

48mm inner diameter — lightweight, corrosion-resistant, stable performance - Premium sealing system

Japan NOK oil seals & Taiwan Hansheng O-rings — no leakage, long durability - Racing-grade shock oil

Mitsubishi (Japan) & Fuchs (Germany) — smooth damping in all conditions

How to Use Our 4x4 Shocks?

Simple tuning for different driving conditions

Compression Damping

Controls how quickly the shock compresses.

- Harder (+) improves body control and reduces roll.

- Softer (-) increases ride comfort.

Rebound Damping

Controls how quickly the shock returns after compression.

- Harder (+) improves handling and stability.

- Softer (-) improves tire contact and traction.

Recommended Starting Settings

| Driving Condition | Compression | Rebound | Description |

|---|---|---|---|

| Everyday driving | 8–10 | 10–12 | The perfect balance of comfort and handling |

| High-speed cruising | 12–14 | 14–16 | Increased stability, reduced float |

| Intense cornering | 16–18 | 14–16 | Strong lateral support |

| Track driving | 20–22 | 18–20 | Maximizes handling precision and responsiveness |

| Offroad driving | 6–8 | 8–10 | Allows for greater travel, keeping the tire grounded |

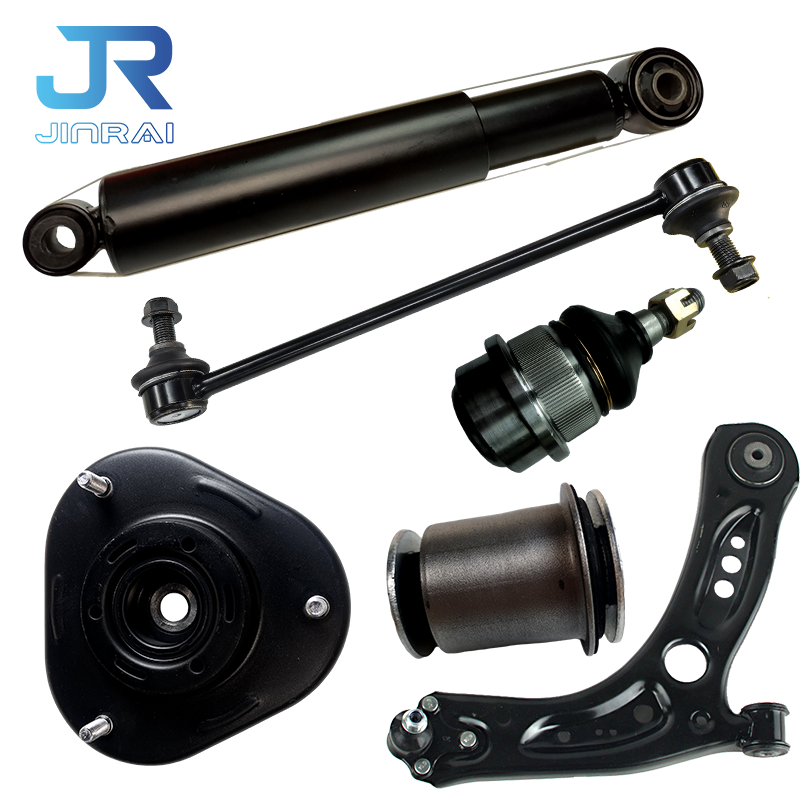

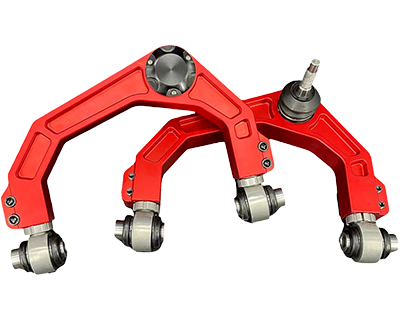

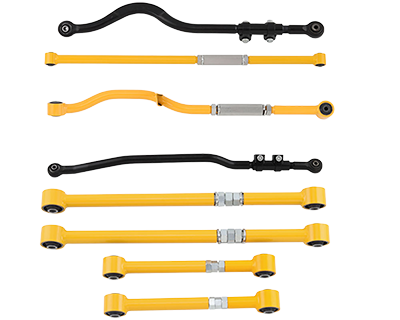

2”+ Lift Upgrade Solutions

Every accessories you need to raise your off-road vehicle

Control Arm

Coil Spring

Lifting Lug

Panhard Rod

Bumper

4x4 Shocks Applications

Wherever you drive, our 4×4 shocks are built to perform.

Rough mountain roads

Our 4×4 shocks are made to take on rocks, bumps, and uneven trails. We focus on keeping wheel movement smooth, body control stable, and vibrations low, so driving in the mountains feels more confident and comfortable.

Desert

our offroad shocks stay stable even on desert. We pay special attention to heat resistance and damping consistency, so performance doesn’t fade when the road gets tough.

Highway

For daily and long-distance driving, our shocks deliver a smoother ride and better stability at high speeds. They help reduce body roll and driver fatigue, making every journey more relaxed.

Harsh weather

Our shocks are tested to work from -40°C to 160°C, handling snow, rain, extreme heat, and heavy-duty environments with the same reliable performance.

Offroad Shock Absorber Factory

Founded in 2010 and located in Wuhu, Anhui Province, our off-road shock absorber factory covers 2,000㎡ and employs over 70 skilled workers. Over the years, we have developed upgrade suspension solutions for more than 1,000 vehicle models, delivering high-quality offroad products at competitive prices.

Partner with us and take your business to the next level — with reliable products, innovative designs, and consistent support, we help you stand out in the off-road market.

How We Control Quality?

Strong manufacturing. Reliable performance. Consistent quality.

Raw Material Quality Control

Quality control starts from the source. All critical raw materials are inspected before entering production:

- Cylinder tubes: material strength, wall thickness, and dimensional tolerance

- Piston rods: hardness, straightness, and surface condition

- Seals and rubber components: heat resistance and aging performance

Only qualified materials are approved for production.

In-Process Inspection

During machining and surface treatment, we apply strict In-Process Quality Control (IPQC):

- Chrome plating thickness and adhesion on piston rods

- Inner surface roughness and concentricity of cylinder tubes

- Dimensional accuracy of pistons and valve components

This ensures every key component meets design requirements before assembly.

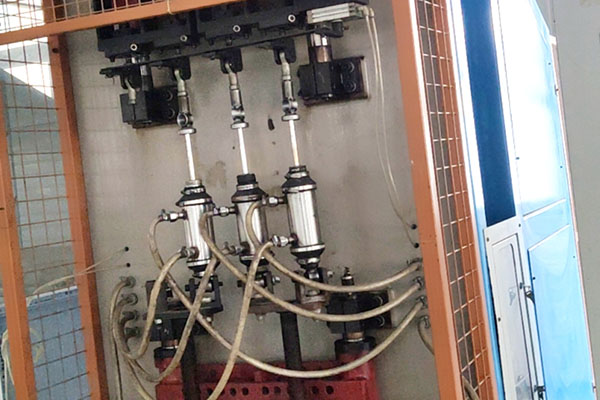

Standardized Assembly Control

Assembly accuracy directly affects shock absorber performance. To ensure consistency:

- Vacuum oil filling is used to eliminate air bubbles

- Precise oil volume control for uniform damping performance

- Standard Operating Procedures applied at critical assembly stations

This minimizes human error and guarantees product consistency.

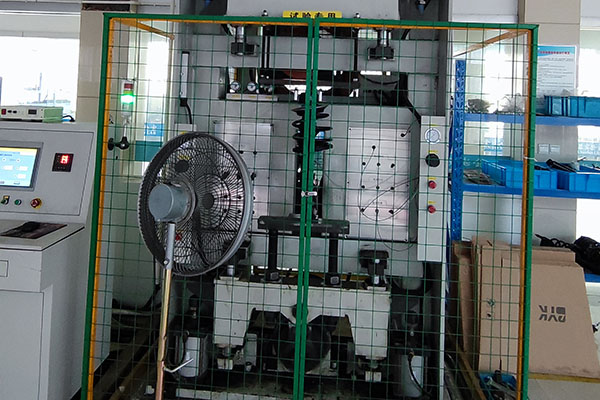

100% Performance and Sealing Inspection

Every off-road shock absorber is fully tested before shipment:

- Damping force test (compression and rebound)

- Stroke and movement inspection

- Leak and sealing performance check

Only products that pass all inspections are released for delivery.

Durability and Fatigue Testing

To ensure long-term reliability, we conduct regular durability tests on batch samples:

- High-frequency fatigue cycling

- High-temperature continuous operation tests

- Simulated off-road impact conditions

These tests verify performance stability under extreme operating conditions.

Feedback-Based Improvement

We actively collect customer and market feedback and use it to:

- Optimize damping tuning

- Improve structural design

- Upgrade future product generations

Quality control is not a one-time process, but a continuous improvement cycle.

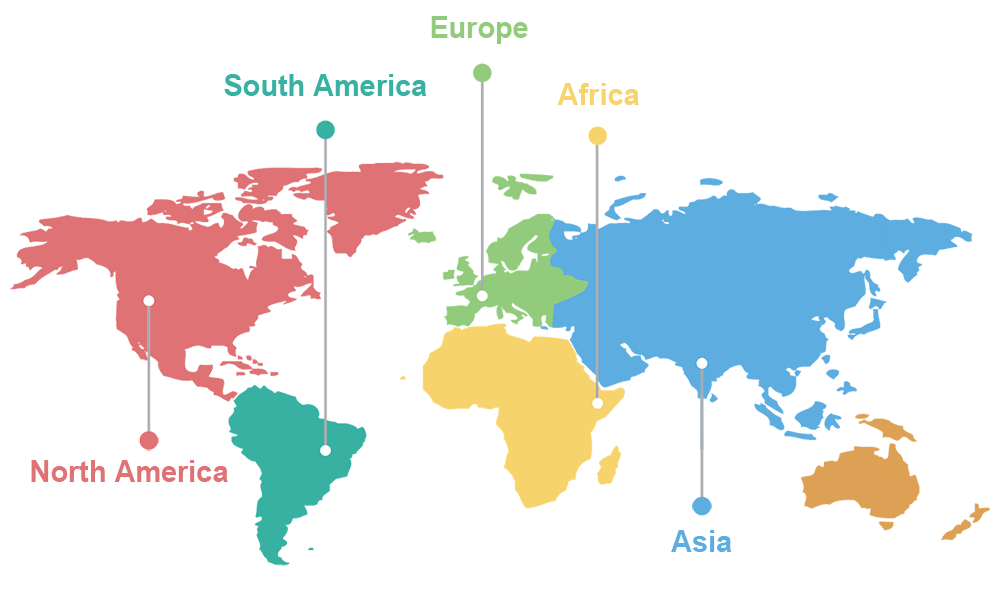

Our Main Markets

North America

America, Canada, Mexico, Guatemala, El Salvador, Honduras, Costa Rica, Panama

South America

Colombia, Venezuela, Suriname, Ecuador, Peru, Bolivia, Brazil, Argentina, Chile

Europe

Finland, Poland, UK, France, Malta, Spain, Portugal, Andorra, Sweden, Belarus, Monaco

Africa

Egypt, Libya, Sudan, Tunisia, Algeria, Morocco, Kenya, Tanzania, Uganda, Gabon, Burkina Faso, Nigeria, Cape Verde, Côte d’Ivoire, Ghana, Zambia, Angola, Zimbabwe, Malawi, South Africa, Madagascar

Asia

South Korea, Japan, Philippines, Vietnam, Laos, Cambodia, Myanmar, Thailand, Malaysia, Indonesia, Bangladesh, India, Pakistan, Sri Lanka, Iraq, Iran, Syria, Jordan, Lebanon, Israel, Palestine, Saudi Arabia, Bahrain, Qatar, Kuwait, United Arab Emirates, Oman, Yemen, Turkey

Why Choose Us?

As a offroad shock absorber factory with rich experience, we provide full support to help you grow your business with ease.

OE Quality

Make production according to OE standards

Competitive Price

Give you factory direct selling prices

Lower MOQ

1 set available

OEM&ODM

Support do your customized brand package

Warranty

1 Year after you receive our products

Your challenge VS Our solution

We understand your challenges, so we’ve built solutions for you

Your Challenge

- Hard to Choose the Right Brand

“All of them claim to be nitrogen gas shocks, but the quality varies massively. Some perform amazingly well, while others feel like complete garbage. It’s really hard to know which one is actually reliable.”

- Too Hard or Too Soft

“I chose nitrogen gas offroad shocks expecting better control and comfort, but in reality they feel too stiff and harsh. On normal roads, every small bump is clearly transmitted to the cabin, making daily driving uncomfortable and tiring.”

- Pressure Loss Over Time

“I bought a 4×4 shock from another supplier. The shocks felt great when they were new, but after about six months, the performance clearly dropped. They don’t feel as firm and responsive as before.”

- One Failure, Full Replacement

“Once my shock performance starts to fade, there is no way to fix it. I have no choice but to replace the entire shock absorber, which makes the long-term cost much higher than expected.”

Our Solution

- Factory Quality You Can Trust

Our 4×4 shocks are manufactured in our own factory, allowing us to control both cost and quality from the source. Every unit goes through multiple performance and durability tests before shipment.

- Adjustment by Our Professional Guide

We provide adjustable nitrogen offroad shock absorbers that can be tuned according to different driving styles and terrain conditions. More importantly, our technical team offers professional guidance and clear instructions, helping you set the correct damping level.

- Long-Term Pressure Stability

Our nitrogen gas shocks are built with a multi-layer sealing structure and high-quality oil seals to prevent gas leakage over time, ensuring stable internal pressure and reliable performance within 2 years.

- Recharge Instead of Replace

Our 4×4 shock absorbers are designed with a rechargeable nitrogen gas structure, allowing you to restore performance instead of replacing the whole product.

More Than A Supplier, Your Trusted Partner

Together with our clients, we build stronger markets through trust, quality, and long-term cooperation.

Every year, we attend major automotive exhibitions worldwide. You can find us at Automechanika in Las Vegas, Mexico, Dubai, and Shanghai, or at the Canton Fair. We warmly welcome you to visit our booth and discuss business face-to-face.

We warmly welcome customers to visit our factory at any time. See your orders being produced firsthand and experience our team and facilities in action. Let’s build a reliable, long-term business relationship together.

To us, customers are more than clients. Through shared experiences, discussions, and collaboration, we learn what they truly need and provide thoughtful solutions, building partnerships grounded in trust and friendship.

Frequently Asked Questions

Everything you want to know about working with us — answered here.

Are you a manufacturer or a trading company?

What is Your MOQ?

Do you offer customized packaging and branding?

What is your warranty policy?

What payment terms do you accept?

Contact Us

You can send us your inquiry lists, requirements, or suggestions using the following form. We will reach you asap.