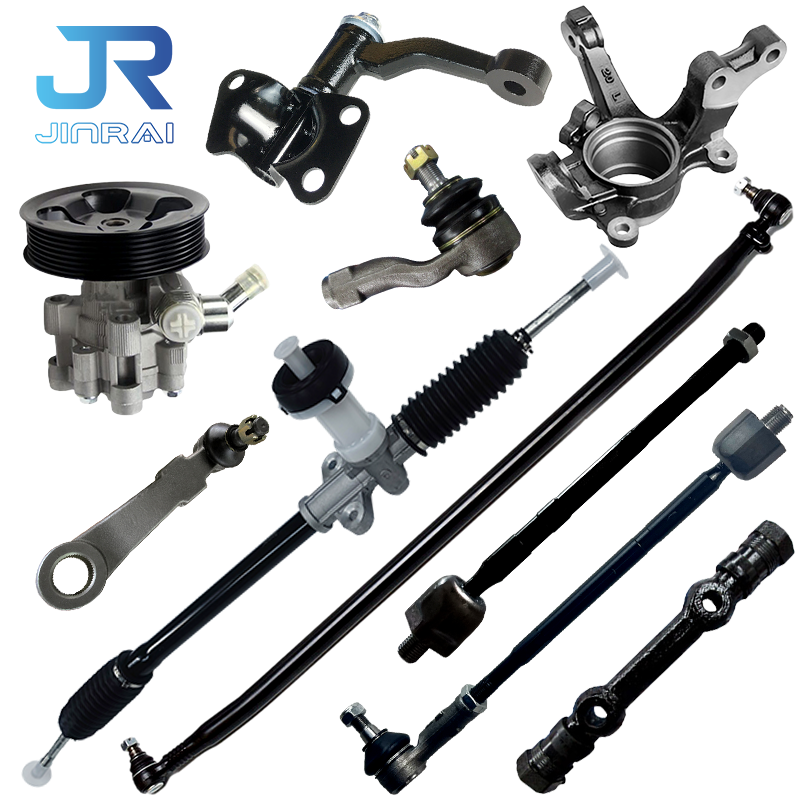

Wholesale Tie Rod End Manufacturer

Factory Prices | OE Quality | Customization Service

Tie Rod End Manufacturer in China

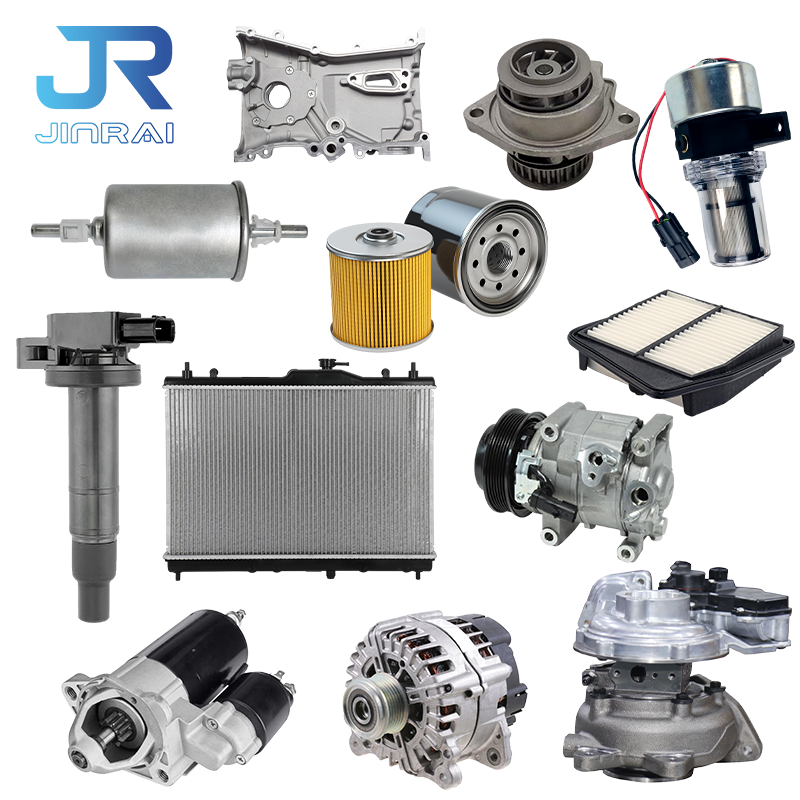

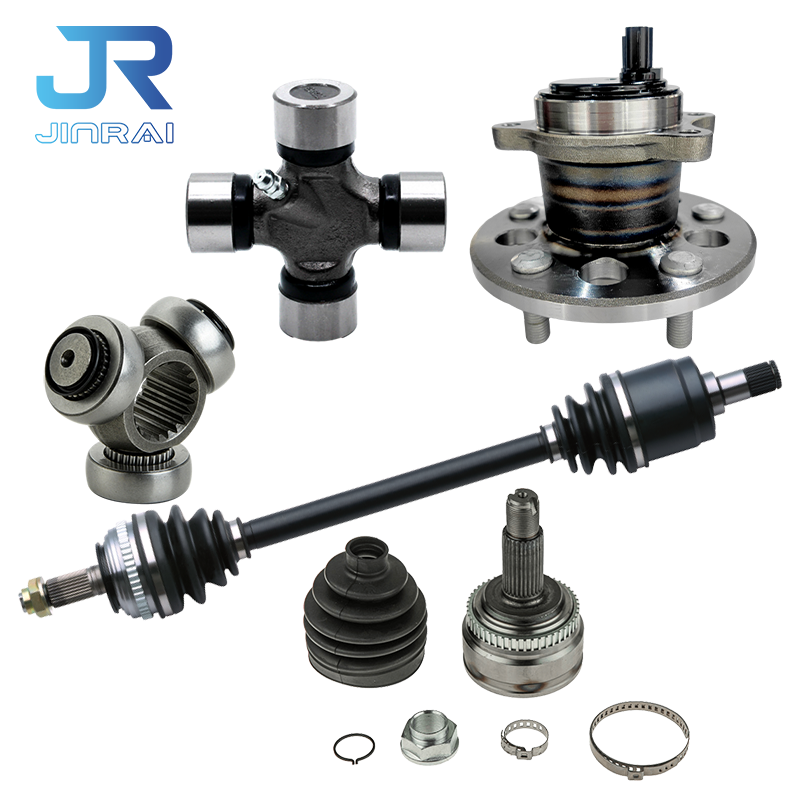

Anhui Goldenstar Auto Parts is a professional tie rod end manufacturer with over 20 years of experience serving the global automotive aftermarket. As a direct factory, we focus on helping distributors, importers, and aftermarket brands build competitive and reliable steering product lines.

Our product range covers a wide selection of Japanese, Korean, European, American, and Chinese vehicle applications, including passenger cars, trucks, and commercial vehicles. With extensive model coverage and continuous expansion of references, we help our partners respond quickly to customer inquiries and avoid missed sales due to limited catalog availability.

In addition, we provide flexible private-label solutions to strengthen your brand presence. Customized laser marking, logo printing, brand labels, color bags, inner boxes, and outer cartons are available to match your market positioning while keeping costs under control.

If you are searching for a reliable tie rod end manufacturer who understands the real needs of global markets, Anhui Goldenstar Auto Parts is ready to support your long-term business growth.

Our Tie Rod Ends Advantages

- Accurate Fitment

Designed with accurate dimensions and correct threading to ensure easy installation and proper steering alignment. - Strong Housing Construction

Built from high-strength materials to withstand impact and road stress, keeping the structure solid over time. - Hardened Ball Stud

Processed for high hardness and smooth rotation, improving steering response and reducing wear. - Wear-Resistant Internal Design

Quality bearing materials maintain proper tightness and help prevent premature looseness. - Reliable Dust Boot Protection

Durable sealing keeps out water and dirt, protecting internal components and extending service life. - Anti-Corrosion Surface Treatment

Protective coating resists rust and corrosion, especially in harsh environments.

Our Tie Rod Ends Application

What you need is exactly what we offer.

Japanese vehicles

Toyota, Honda, Nissan, Mazda, Subaru, Mitsubishi, Suzuki, Isuzu, Hino, Daihatsu

Korean Vehicles

Hyundai, Kia, Genesis, SsangYong

European Vehicles

DAF, Renault, Peugeot, Citroën, Fiat, Iveco, Volvo, Scania, Land Rover

American Vehicles

Ford, Chevrolet, Dodge, Tesla, Jeep, Cadillac, Buick

German Vehicles

Volkswagen, BMW, Audi, Porsche, Mercedes-Benz, MAN, Opel

Tie Rod End Ordering Notes

Details should be confirmed with our sales team before purchase

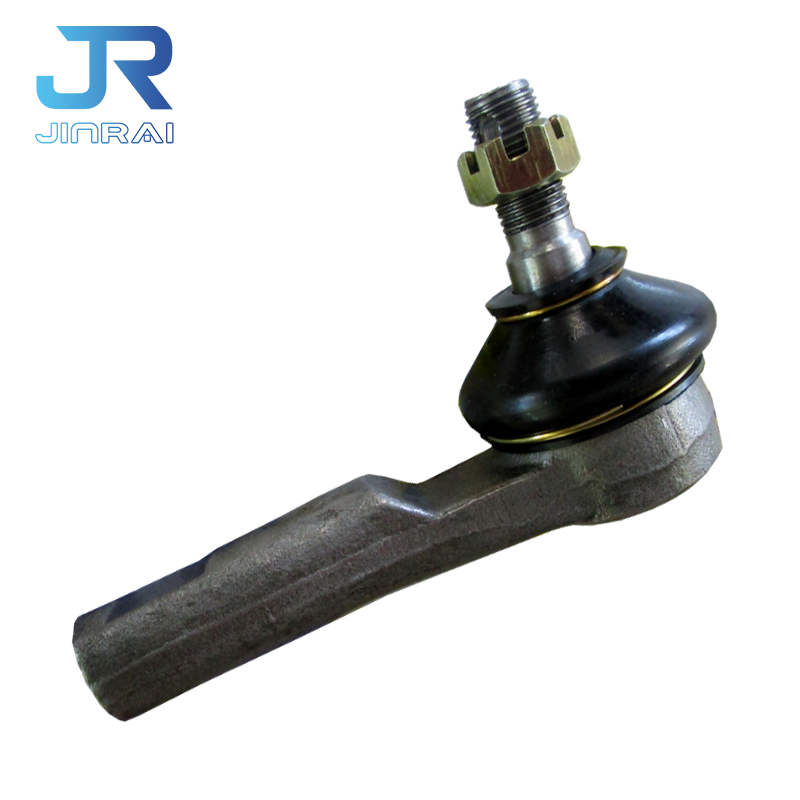

Surface Finish & Color

We offer multiple surface finish options to meet different market preferences. According to our experience, customers in South America prefer black color, and clients in North Africa widely accept black or silver color.

Natural Color

Black Color

Silver Color

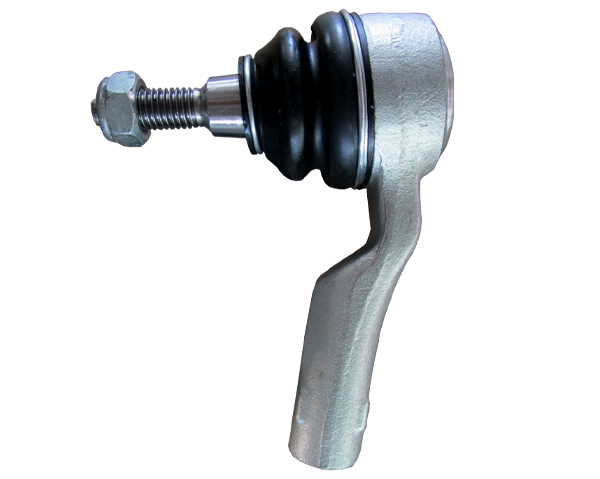

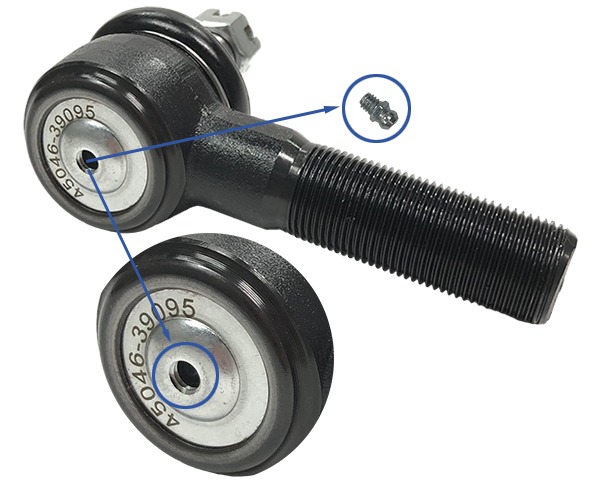

Tie Rod End Grease Nipple Design

Tie Rod End With grease nipple

Advantages:

- Allows regular lubrication, effectively reducing friction and internal wear

- Extends service life, especially under heavy loads or harsh road conditions

- Preferred in markets where routine vehicle maintenance is standard practice

Disadvantages:

- Requires periodic greasing during regular servicing

- Incorrect or excessive lubrication may cause contamination or inconsistent performance

Tie Rod End Without grease nipple

Advantages:

- Maintenance-free design with no need for periodic lubrication

- Fully sealed structure reduces the risk of dirt and water intrusion

- Ideal for users who prefer easy installation and minimal servicing

Disadvantages:

- Cannot be re-lubricated once the factory grease is exhausted

- Service life largely depends on the initial grease quality and sealing effectiveness

Twist Force

The video demonstrates the tie rod end with standard tightening torque, suitable for most common applications. If a higher torque specification is required, please inform us before placing your order. The specific torque requirement will be clearly stated on the order and confirmed before production.

FAQ of Tie Rod Ends

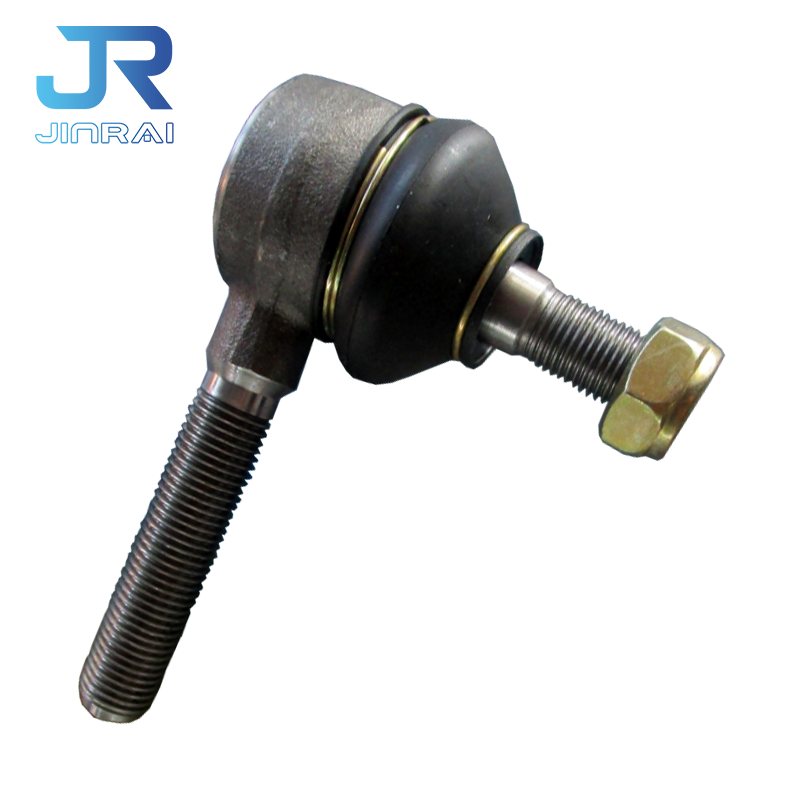

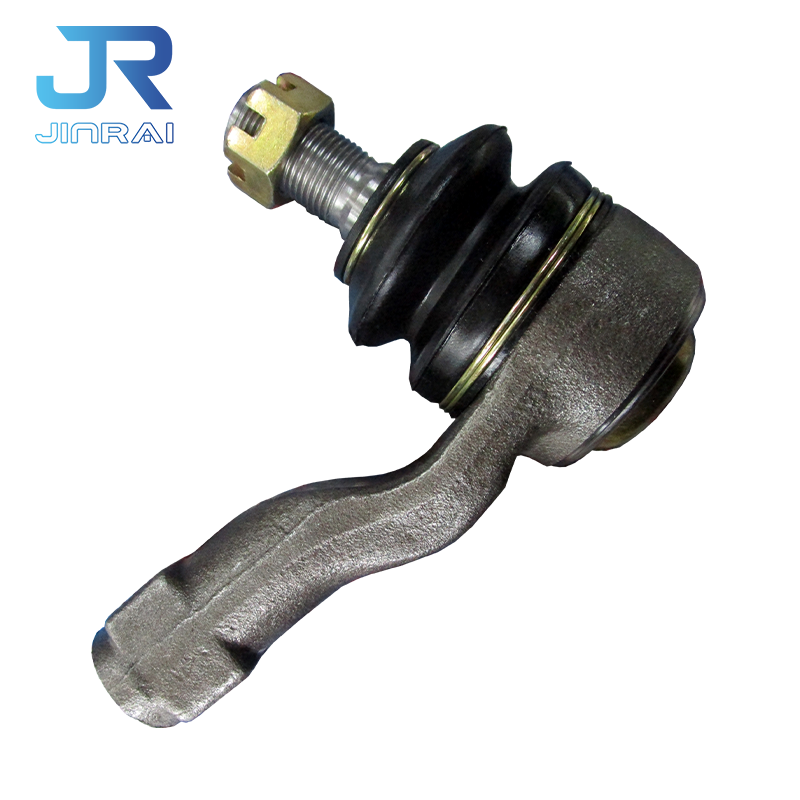

What is a tie rod end?

A tie rod end is a critical steering component that connects the steering rack (or center link) to the steering knuckle on each front wheel. It allows steering force to be transferred from the steering wheel to the wheels while still permitting vertical suspension movement.

Tie rod ends are designed with a ball-and-socket structure, enabling smooth articulation as the vehicle turns or travels over uneven roads. They play a key role in maintaining proper wheel alignment and precise steering response.

In most vehicles, tie rod ends are classified as inner tie rod ends and outer tie rod ends, working together as part of the steering linkage system.

How Long Does a Tie Rod End Last?

The service life of a tie rod end typically ranges from 80,000 to 150,000 km, depending on driving conditions, vehicle load, and part quality.

Factors that can shorten tie rod end lifespan include:

- Rough or off-road driving

- Poor road conditions

- Torn or damaged dust boots

- Lack of lubrication or contamination by dirt and water

High-quality tie rod ends made with durable ball studs, strong housings, and reliable sealing systems tend to last significantly longer and provide more consistent steering performance over time.

What Does a Tie Rod End Do?

The primary function of a tie rod end is to control and transmit steering movement. When the driver turns the steering wheel, the tie rod end ensures the front wheels respond accurately and consistently.

In addition to steering control, tie rod ends also help:

- Maintain correct toe alignment

- Keep the wheels pointed in the intended direction

- Stabilize the vehicle during cornering and braking

Without properly functioning tie rod ends, steering becomes loose, unpredictable, and unsafe—especially at higher speeds.

Bad tie rod end Symptoms

A worn or failing tie rod end often shows clear warning signs. Common symptoms include:

- Loose or wandering steering, especially at highway speeds

- Uneven or rapid tire wear, caused by incorrect alignment

- Clunking or knocking noises when turning or driving over bumps

- Steering wheel vibration or poor steering return

- Visible play when the front wheels are inspected

Ignoring these symptoms can lead to further suspension damage, alignment issues, and increased safety risks.

Tie Rod End Factory

Founded in 2005, our tie rod end factory has grown into a large-scale production base covering 120,000㎡, supported by over 500 skilled workers. All key production processes are completed in-house. From forging and machining to heat treatment, assembly, and final inspection, every component is manufactured under our direct control.

We strictly manage quality at every step and ensure that each tie rod end meets high-performance and durability standards. With advanced production lines and modern testing equipment, we verify strength, hardness, dimensional accuracy, and long-term reliability before shipment.

Our current monthly output reaches 300,000 pieces, enabling us to handle both regular volume orders and urgent demand efficiently. With strong production capacity and organized planning, your orders are scheduled properly and delivered on time — without unnecessary delays.

Manufacture Process of OE-Quality Tie Rod Ends

Strong manufacturing. Reliable performance. Consistent quality.

Material Preparation

Everything starts with the right steel. High-strength alloy steel is carefully selected to ensure excellent tensile strength, impact resistance, and long service life. Material certificates are verified before production begins.

Precision Forging

The housing is hot-forged to achieve a dense internal structure and superior mechanical strength. Forging improves durability and prevents cracking under heavy steering loads.

CNC Machining

After forging, components are processed using high-precision CNC machines. This ensures accurate dimensions, smooth threads, and proper tolerance control — critical for steering stability and easy installation.

Heat Treatment

Ball studs undergo controlled heat treatment to increase hardness while maintaining toughness. This step ensures wear resistance and prevents premature failure during long-term use.

Surface Treatment & Anti-Corrosion Protection

To enhance durability, parts receive surface treatments such as phosphating, electrophoretic coating, or zinc plating, offering strong corrosion resistance, especially in harsh road conditions.

Ball Pin Grinding & Polishing

The ball stud surface is finely ground and polished to achieve smooth movement inside the housing. This reduces friction and ensures responsive steering performance.

Assembly & Preload Adjustment

Each tie rod end is assembled with grease filling and proper preload adjustment. Correct preload ensures tight fit without excessive stiffness, balancing steering precision and flexibility.

100% Quality Inspection

- Dimensional accuracy check

- Hardness testing

- Pull-out force testing

- Swing torque testing

- Thread inspection

Packaging & Delivery

Tie rod ends are packed according to customer needs, including:

- Neutral packaging

- Customized brand packaging

- Barcode and labeling support

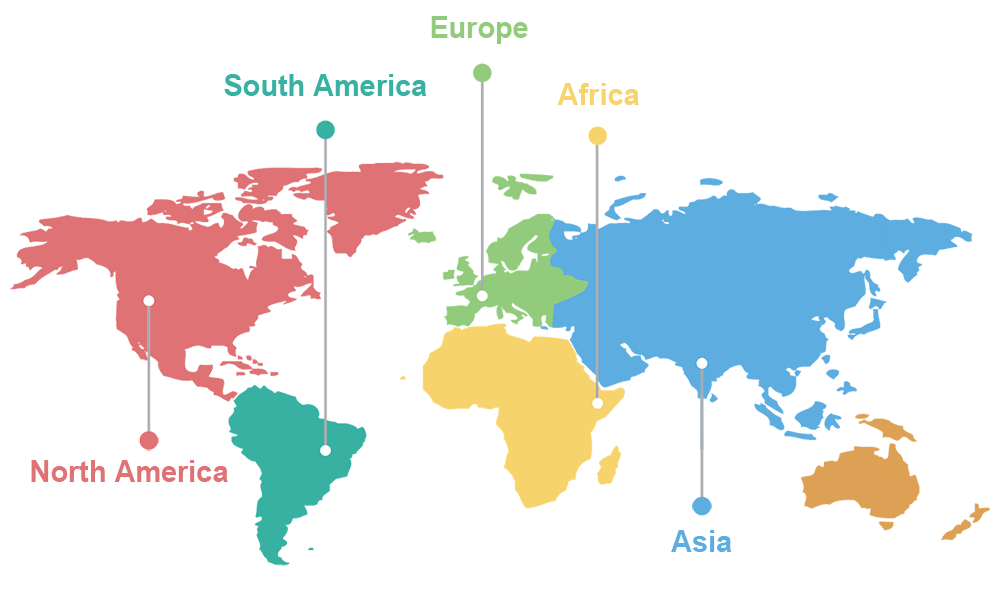

Our Main Markets

North America

America, Canada, Mexico, Guatemala, El Salvador, Honduras, Costa Rica, Panama

South America

Colombia, Venezuela, Suriname, Ecuador, Peru, Bolivia, Brazil, Argentina, Chile

Europe

Finland, Poland, UK, France, Malta, Spain, Portugal, Andorra, Sweden, Belarus, Monaco

Africa

Egypt, Libya, Sudan, Tunisia, Algeria, Morocco, Kenya, Tanzania, Uganda, Gabon, Burkina Faso, Nigeria, Cape Verde, Côte d’Ivoire, Ghana, Zambia, Angola, Zimbabwe, Malawi, South Africa, Madagascar

Asia

South Korea, Japan, Philippines, Vietnam, Laos, Cambodia, Myanmar, Thailand, Malaysia, Indonesia, Bangladesh, India, Pakistan, Sri Lanka, Iraq, Iran, Syria, Jordan, Lebanon, Israel, Palestine, Saudi Arabia, Bahrain, Qatar, Kuwait, United Arab Emirates, Oman, Yemen, Turkey

Why Choose Us?

As a tie rod end factory with rich experience, we provide full support to help you grow your business with ease.

OE Quality

Make production according to OE standards

Competitive Price

Give you factory direct selling prices

Lower MOQ

120pcs each model

OEM&ODM

Support do your customized brand package

Warranty

1 Year after you receive our products

Your challenge VS Our solution

We focus on solving these problems before they become your problems.

Your Challenge with other suppliers

- Difficult Communication

“I’ve already shared all the details, but the answers I get are vague or delayed. I feel like I’m repeating myself over and over, and sometimes language differences make communication even harder.”

- Delivery Delays and Broken Promises

“Orders are promised on time, but delays keep piling up. It slows down my sales and damages my reputation with my own customers.”

- Receiving Low or Unstable Quality Products

“I trusted the products, but after selling them, I started receiving returns and refund requests because of quality issues. It’s not just frustrating — it directly hurts my business and reputation.”

- Poor After-Sales Support

“When a problem arises after selling, it’s already stressful. What makes it worse is when some suppliers avoid responsibility or refuse to help.”

Our Solution

- Good Communication

Language is never a barrier. From Spanish to Arabic to Portuguese markets, our team fully understands your needs, the products, and the global trade process, making every discussion fast, clear.

- Fast Delivery on Time

Our production capacity of 300,000pcs/month gives us full control over delivery. Your order is scheduled in advance and completed as promised on time, in full, and without disruption to your business.

- Only Produce OE Quality Products

In-house manufacturing, quality checks at every stage, and 100% inspection before shipment—this is how we eliminate quality risks.

- Excellent After-Sales Service

We offer a 1-year warranty. After your order is placed, a dedicated group with the sales and a manager is set up to ensure any issue is handled quickly at the company level.

More Than A Supplier, Your Trusted Partner

Let’s work together — your success is our mission.

By actively participating in leading global trade shows across North America, Latin America, the Middle East, and Asia, we stay closely aligned with market developments and engage directly with customers to understand real demand better and build lasting partnerships.

We welcome customers to see how their products are made. A factory visit offers full transparency into our production, quality control, and in-house operations, so you can place orders with clarity and confidence.

We work alongside our customers, not just as a supplier, but as a committed partner. Through open communication and collaborative problem-solving, we align with your business goals and support long-term growth.

Frequently Asked Questions

Everything you want to know about working with us — answered here.

Are you a manufacturer or a trading company?

What is Your MOQ?

Do you offer customized packaging and branding?

What is your warranty policy?

What payment terms do you accept?

Contact Us

You can send us your inquiry lists, requirements, or suggestions using the following form. We will reach you asap.